A kind of production method of α-high-strength gypsum powder

A production method and technology of gypsum powder, which is applied in the field of phosphogypsum production of α-high-strength gypsum powder, can solve the problems of not strict requirements on production line capacity, free water content, difficult sales of intermediate products, and promotion of unfavorable applications, so as to improve the utilization rate of raw materials , High data accuracy, conducive to the effect of regulation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

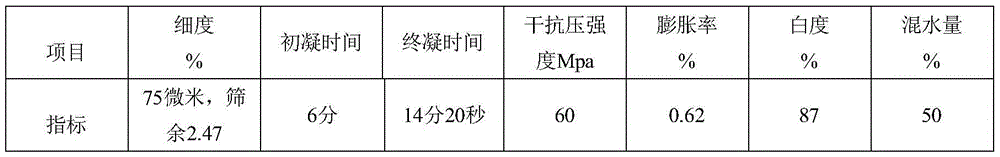

Embodiment 1

[0036] A kind of production method of α-high-strength gypsum powder, the steps are as follows:

[0037] (1) Mix 5 tons of phosphogypsum with a mass content of 96% on a dry basis with water to obtain a solid material with a specific gravity of 1200kg / m 3 slurry;

[0038] (2) Add 250 g of a crystal-transforming agent to the slurry prepared in step (1) at one time, and conduct crystal-transforming for 1.5 hours at 115° C. and 0.2 MPa. The described crystal-transforming agent is citrate;

[0039] The heating method is to heat the heat transfer oil with high-pressure steam first, and then use the heated heat transfer oil to heat the slurry;

[0040] During the crystal transformation process, the pressure is adjusted by adding compressed air;

[0041] (3) Remove the material obtained in step (2) to a free water mass content of ≤15%, and dry it at 140° C. for 1 hour; purify and dedust the tail gas generated during the drying process, and discharge the purified and dedusted water va...

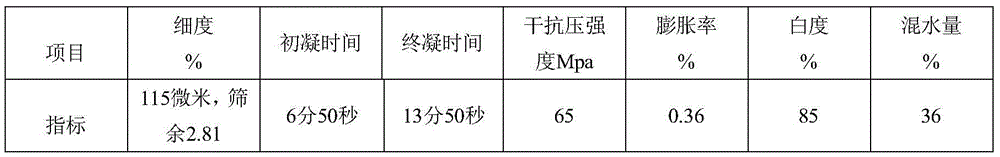

Embodiment 2

[0046] A kind of production method of α-high-strength gypsum powder, the steps are as follows:

[0047] (1) Mix 5 tons of phosphogypsum with a mass content of 95% on a dry basis with water to obtain a solid material with a specific gravity of 1250kg / m 3 slurry;

[0048] (2) Add 500 g of a crystal-transforming agent to the slurry prepared in step (1), and conduct crystal-transforming for 1.8 hours at 118° C. and 0.3 MPa. The described crystal-transforming agent is an alkyl sulfonate;

[0049] The heating method is to heat the heat transfer oil with high-pressure steam first, and then use the heated heat transfer oil to heat the slurry;

[0050] During the crystal transformation process, the pressure is adjusted by adding compressed air;

[0051]The addition method of the crystal transformation agent is added through the pump according to the crystal transformation situation, and can be adjusted in real time;

[0052] (3) Remove the material obtained in step (2) to a free wat...

Embodiment 3

[0057] A kind of production method of α-high-strength gypsum powder, the steps are as follows:

[0058] (1) Mix 5 tons of phosphogypsum with a mass content of 95% on a dry basis with water to obtain a solid material with a specific gravity of 1300kg / m 3 slurry;

[0059] (2) Add 750 g of a crystal-transforming agent to the slurry prepared in step (1) at one time, and conduct crystal-transforming for 2 hours at 122° C. and 0.4 MPa. The described crystal-transforming agent is an alkyl sulfonate;

[0060] The heating method is to heat the heat transfer oil with high-pressure steam first, and then use the heated heat transfer oil to heat the slurry;

[0061] During the crystal transformation process, the pressure is adjusted by adding compressed air;

[0062] (3) Remove the material obtained in step (2) to a free water mass content of ≤15%, and dry it at 145° C. for 1 hour; purify and dedust the tail gas generated during the drying process, and discharge the purified and dedusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com