Method and device for preparing hydroxyl radical solution

A free radical, solution technology, applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problems of poor UV penetration, high treatment cost, low concentration, etc., to achieve optimization Miscible process mode and parameters, improving gas-liquid mass transfer efficiency, and the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

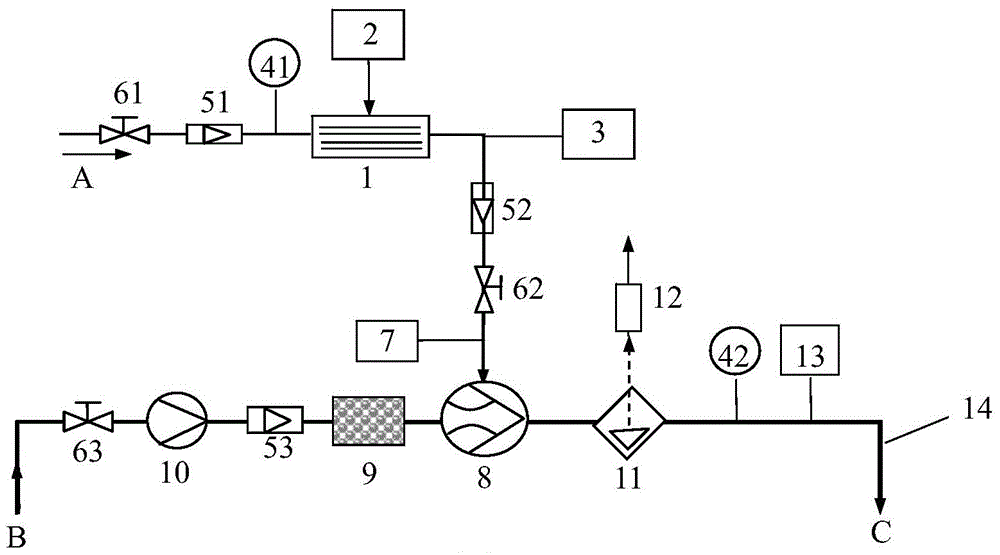

preparation example Construction

[0040] Provide the concrete steps of the preparation method of hydroxyl radical solution below:

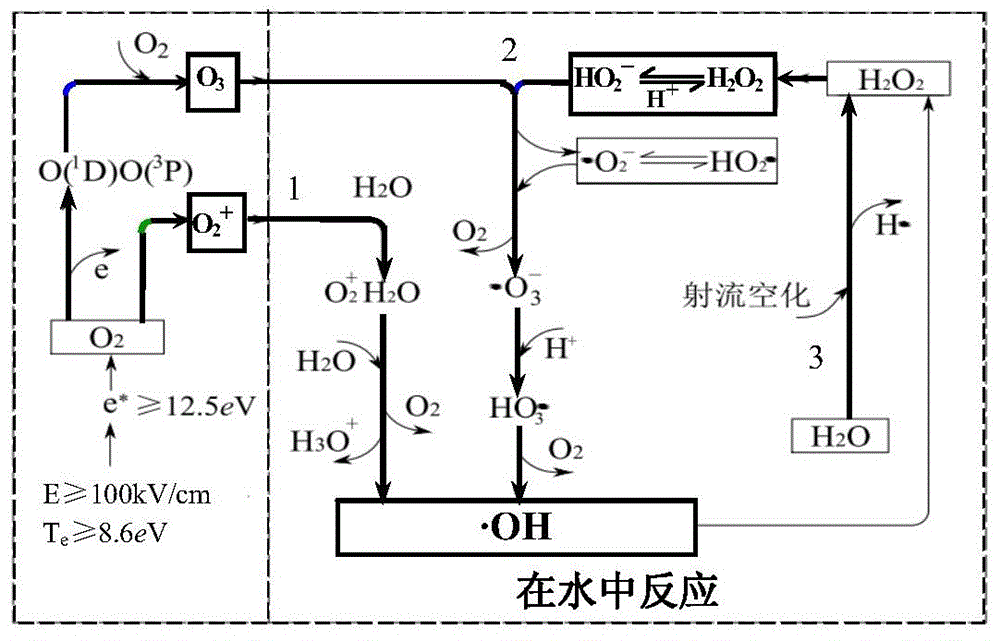

[0041] 1) Start the high-frequency high-voltage power supply 2, which applies an external excitation power to the oxygen plasma generator, and the raw material gas enters the oxygen plasma generator 1 through the polytetrafluoroethylene pipeline for ionization and dissociation. The strong ionization discharge that occurs in the discharge gap of the micro-fluid and the micro-glow alternately cooperates. The characteristic physical parameters of the atmospheric pressure ionization discharge, such as discharge power, critical electric field strength, high-energy electron occupancy, etc., can be used by Stark broadening method and fiber optic spectroscopy. Measure and control the plasma diagnostic method combined with numerical simulation; the concentration of the generated oxygen plasma, especially O 2 + , can be adjusted by the external excitation power of the high-frequency high-v...

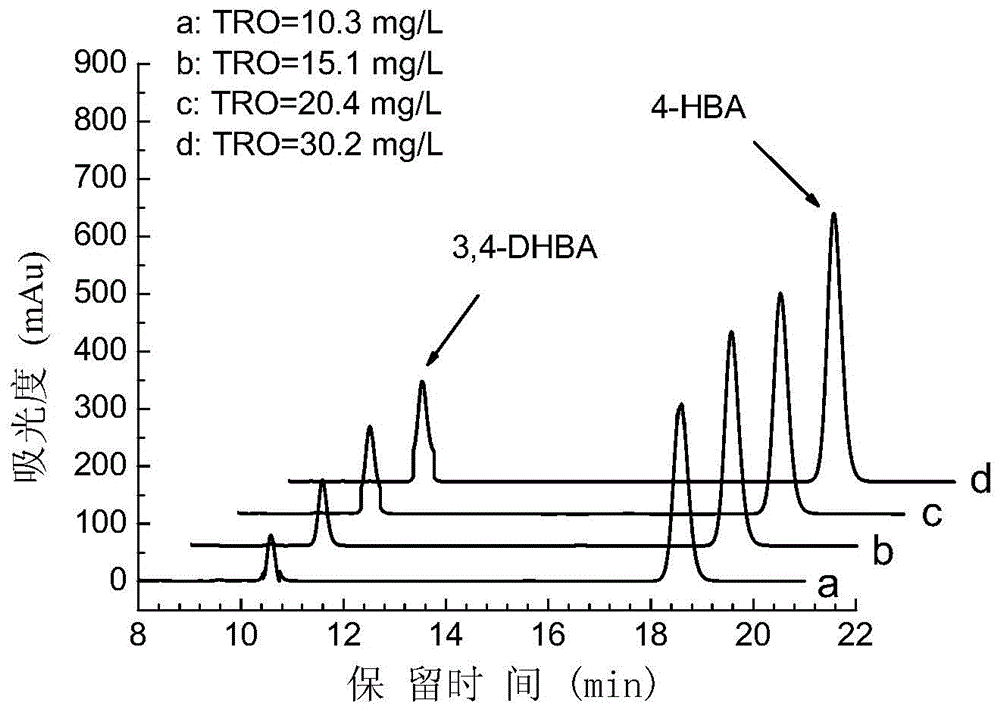

Embodiment 1

[0079] Adjust the discharge power at 100~400W, O 2 The intake air volume is 3.0L / min, and different concentrations of oxygen plasma gas are obtained. The water flow rate is 6-12L / min, and different concentrations of total oxidant (TRO) can be obtained after the oxygen plasma gas is injected into the water. Under the premise of not changing other experimental conditions, 750mL of water samples containing the capture agent 4-HBA with an initial concentration of 1mmol / L, a water body temperature of 15°C, and a pH of 7 were passed through the system, and 150mL of the resulting sample solution was filtered through 0.22μm After membrane filtration, HPLC is used to analyze the content of 3,4-DHBA, which is calculated by measuring the difference of total organic carbon TOC before and after the reaction. OH oxidizes 4-HBA and mineralizes it into CO 2 amount. The content of OH is calculated indirectly by the generation of 3,4-DHBA The amount of OH is related to the mineralization into...

Embodiment 2

[0087] Energy consumption test of hydroxyl radical solution preparation device.

[0088] The amount of OH generated by the hydroxyl radical generator is 25 to 50 m 3 / h, the total flow of water to be treated in the main pipeline is 400~500m 3 / h. Externally commissioned Dalian Energy Saving Technology Service Center to test the energy consumption of OH generators and the production of hydroxyl solution, and the Modern Analysis Center of Dalian Institute of Chemical Physics, Chinese Academy of Sciences to test the concentration of total oxidant (TRO) to calculate the energy consumption per ton of water treated and cost. The test results are shown in Table 2.

[0089] Energy consumption of OH generating device: power quality analyzer (model: FLUKE 435-II, accuracy level 0.5), detect voltage, current, power factor and electric energy at the power input terminal of OH device.

[0090] ·OH solution generation: intelligent electromagnetic flowmeter (model: LDBE-80, precision gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com