Membrane material for transfusion soft bag and application of membrane material

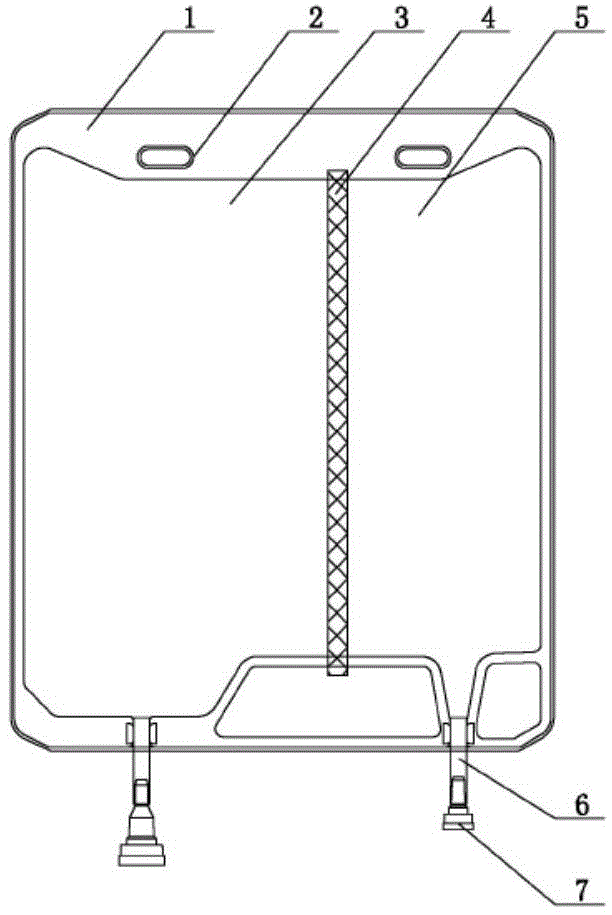

A technology for infusion soft bags and film materials, applied in the field of film materials for infusion soft bags, to achieve good heat resistance and printing performance, excellent drop resistance, and uniform tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

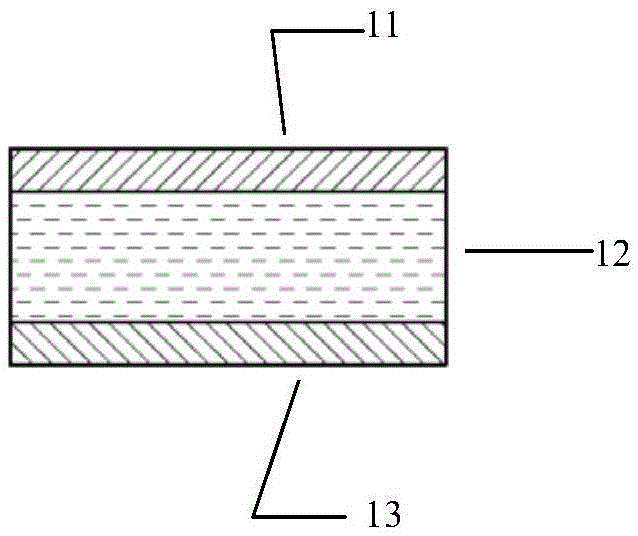

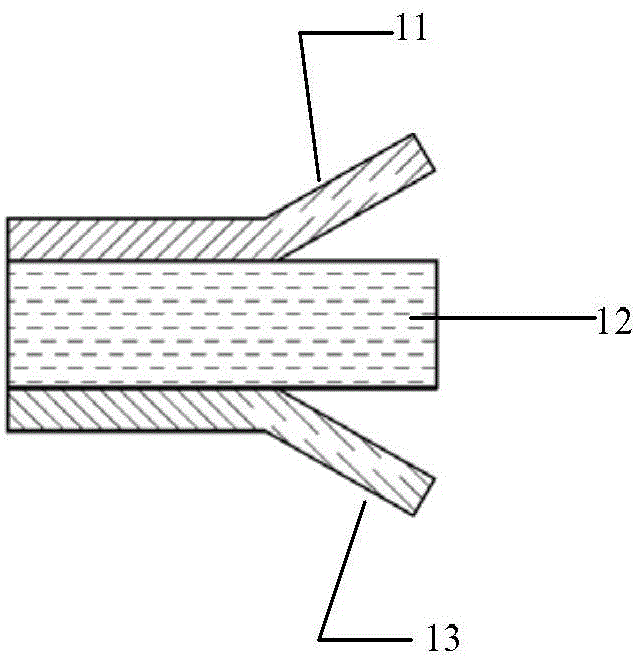

[0050] The outer layer formulation adopts 81% polypropylene (melting point 159.5°C, density 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 5.6g / 10min, the tensile strength is 21MPa, and the impact strength is 31KJ / m 2 ), and 6% by weight of polyethylene, 5% by weight of styrene-isoprene-styrene, 8% by weight of styrene-ethylene-butylene-styrene (density 0.887g / cm 3 , melt flow rate is 3.1g / 10min), add 0.07% 2,6-tert-butyl-4-methylphenol of the above-mentioned material percentage by weight and carry out physical mixing in a high-speed stirrer, and the mixed material can be used directly Or use it after twin-screw granulation.

[0051] The middle layer formula adopts the weight percentage to be 42% polypropylene (density is 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 3.7g / 10min, the tensile strength is 15MPa, and the impact strength is 19KJ / m 2 ), and 11% by weight of polyethylene, 47% by weight of sty...

Embodiment 2

[0058]The outer layer formulation adopts 83% polypropylene (melting point 161.0°C, density 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 5.6g / 10min, the tensile strength is 21MPa, and the impact strength is 31KJ / m 2 ), with 8% by weight polyethylene, and 9% by weight styrene-ethylene-butylene-styrene (density 0.887g / cm 3 , the melt flow rate is 3.1g / 10min), adding 0.07% of the weight percentage of the above materials 2,6-tert-butyl-4-methylphenol is physically mixed in a high-speed stirrer, and the mixed material can be used directly Or use it after twin-screw granulation.

[0059] The middle layer formula adopts 50% polypropylene by weight percentage (density is 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 3.7g / 10min, the tensile strength is 15MPa, and the impact strength is 19KJ / m 2 ), and 10% by weight of polyethylene, 35% by weight of styrene-ethylene-butylene-styrene (density 0.887g / cm 3 , melt...

Embodiment 3

[0065] The outer layer formulation adopts 95% by weight polypropylene (melting point 159.5°C, density 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 5.6g / 10min, the tensile strength is 21MPa, and the impact strength is 31KJ / m 2 ), and 0.5% by weight of polyethylene, 4.5% by weight of styrene-ethylene-butylene-styrene (density 0.887g / cm 3 , the melt flow rate is 3.1g / 10min), adding 0.07% of the weight percentage of the above materials 2,6-tert-butyl-4-methylphenol is physically mixed in a high-speed stirrer, and the mixed material can be used directly Or use it after twin-screw granulation.

[0066] The middle layer formula adopts the weight percent as 20% polypropylene (density is 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 3.7g / 10min, the tensile strength is 15MPa, and the impact strength is 19KJ / m 2 ), and 20% by weight of polyethylene, 60% by weight of styrene-ethylene-butylene-styrene (density 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com