Brazing method of hermetically sealed seat component

A brazing method and sealing seat technology, which is applied in the direction of welding medium, welding equipment, welding/welding/cutting items, etc., can solve the very high assembly and positioning requirements of sealing seat components, easy deformation of the seat body, chemical composition, etc. It can achieve the effect of high production efficiency, high qualified rate of brazing, and guarantee of sealing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

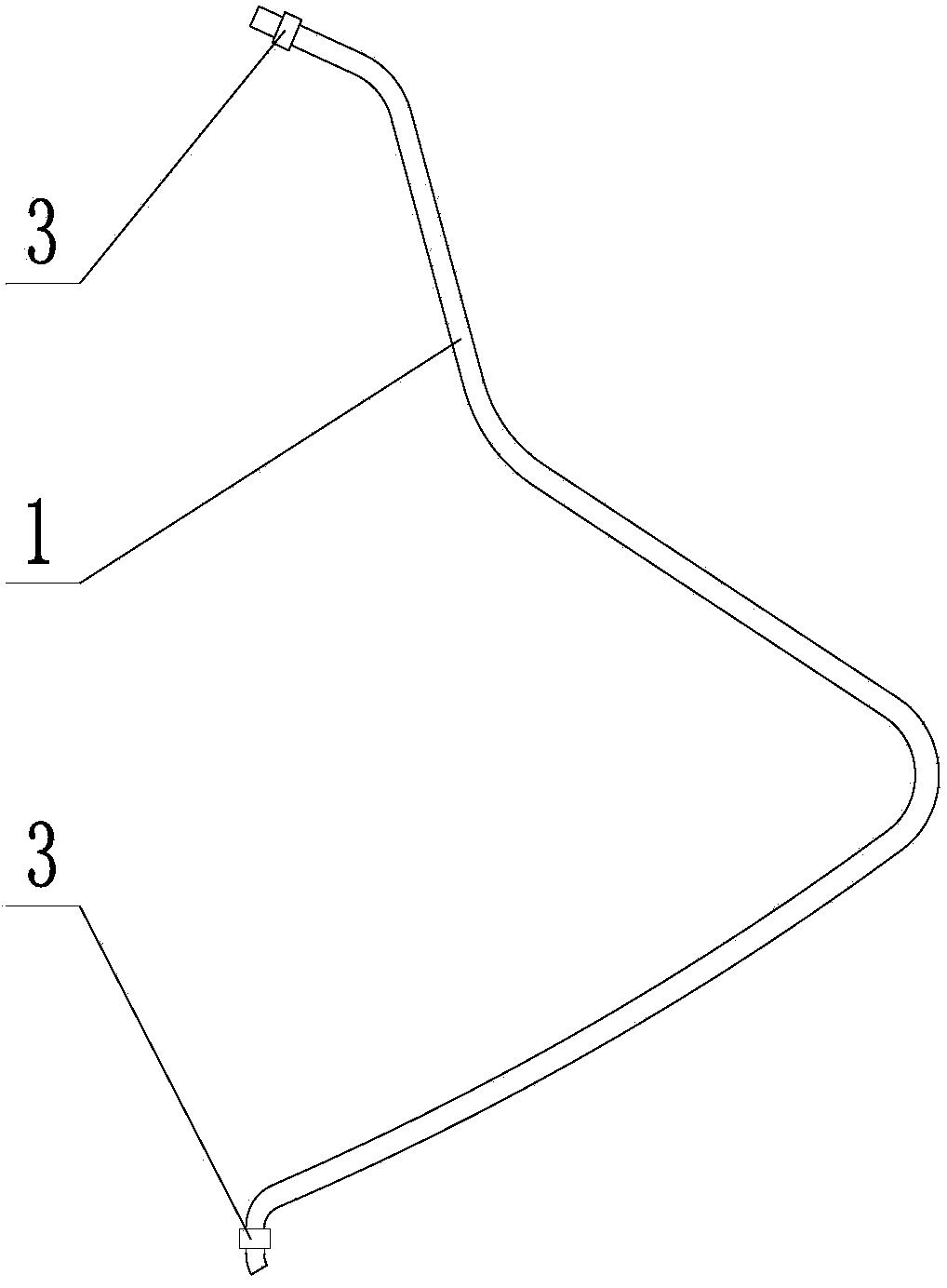

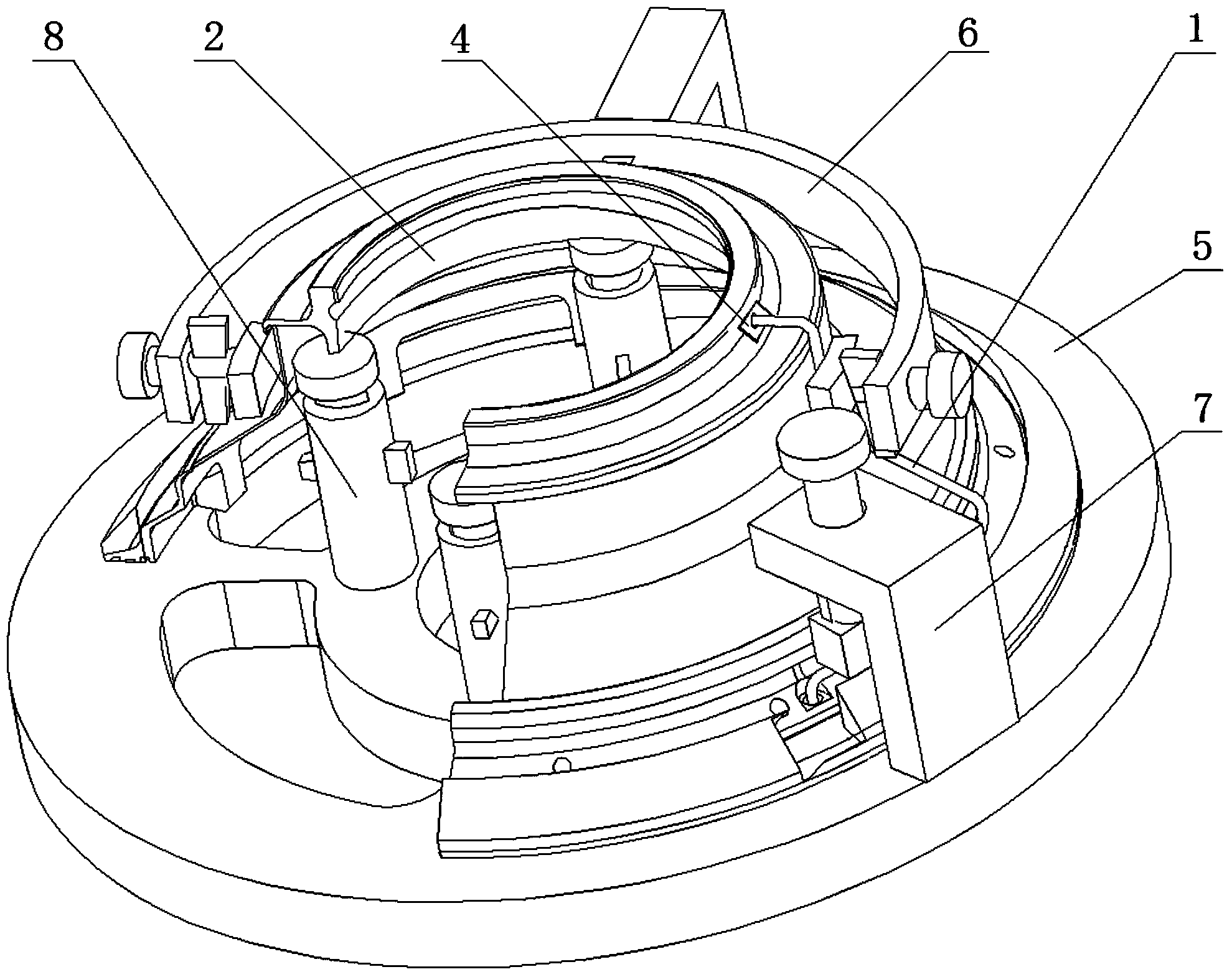

[0032] The seat body of the sealing seat assembly is TC4 titanium alloy, the conduit is 1Cr18Ni9Ti stainless steel, the conduit diameter is φ5mm, the depth of the two ends of the conduit inserted into the upper and lower mounting side holes of the seat body is 3mm, the upper and lower mounting edge holes of the seat body are The height difference is 120.5mm.

[0033] The type of vacuum furnace used in the brazing process is VBFV-300, the working temperature of the equipment is 550-1350°C, the temperature uniformity is ±5°C, and the ultimate vacuum pressure is 0.001Pa.

[0034] The brazing method of the above-mentioned sealing seat assembly includes the following steps:

[0035] Step 1: Preparation before welding

[0036] ① Prepare a BAg71CuNiLi strip-shaped finished solder with a thickness of 0.1mm, and then use emery gauze to clean the oxide film on the surface of the solder until it shows a metallic luster;

[0037] ② Use emery gauze to clean the oxide film at the two ends...

Embodiment 2

[0056] The seat body of the sealing seat assembly is TC4 titanium alloy, the conduit is 1Cr18Ni9Ti stainless steel, the conduit diameter is φ5mm, the depth of the two ends of the conduit inserted into the upper and lower mounting side holes of the seat body is 3.5mm, the upper and lower mounting sides of the seat body are The height difference is 120.8mm.

[0057] The type of vacuum furnace used in the brazing process is VBFV-300, the working temperature of the equipment is 550-1350°C, the temperature uniformity is ±5°C, and the ultimate vacuum pressure is 0.001Pa.

[0058] The brazing method of the above-mentioned sealing seat assembly includes the following steps:

[0059] Step 1: Preparation before welding

[0060] ① Prepare a BAg71CuNiLi strip-shaped finished solder with a thickness of 0.1mm, and then use emery gauze to clean the oxide film on the surface of the solder until it shows a metallic luster;

[0061] ② Use emery gauze to clean the oxide film at the two ends of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com