High-temperature superconducting motor liquid cooling air gap armature stator structure and assembling method

A liquid cooling and high temperature superconducting technology, applied in the shape/style/structure of winding conductors, cooling/ventilation devices, electromechanical devices, etc., can solve the problems that cannot meet the heat dissipation requirements of the stator armature, and achieve simplified connection structure and assembly process, simplification of molding process, effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

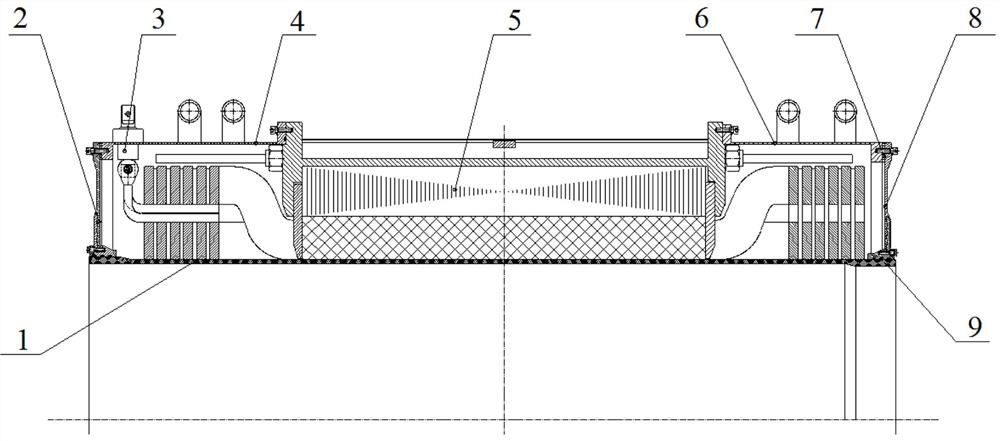

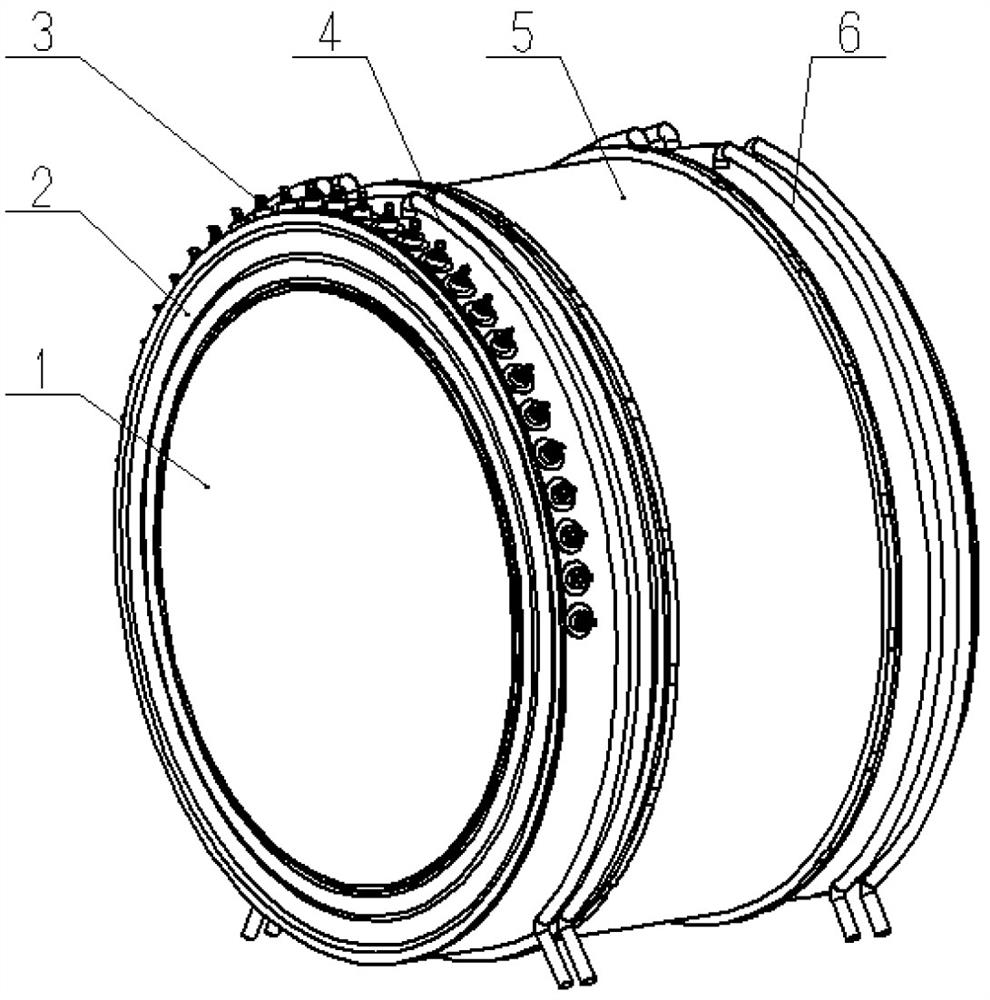

[0053] like Figure 1 to Figure 7 Shown is a basic embodiment of the invention.

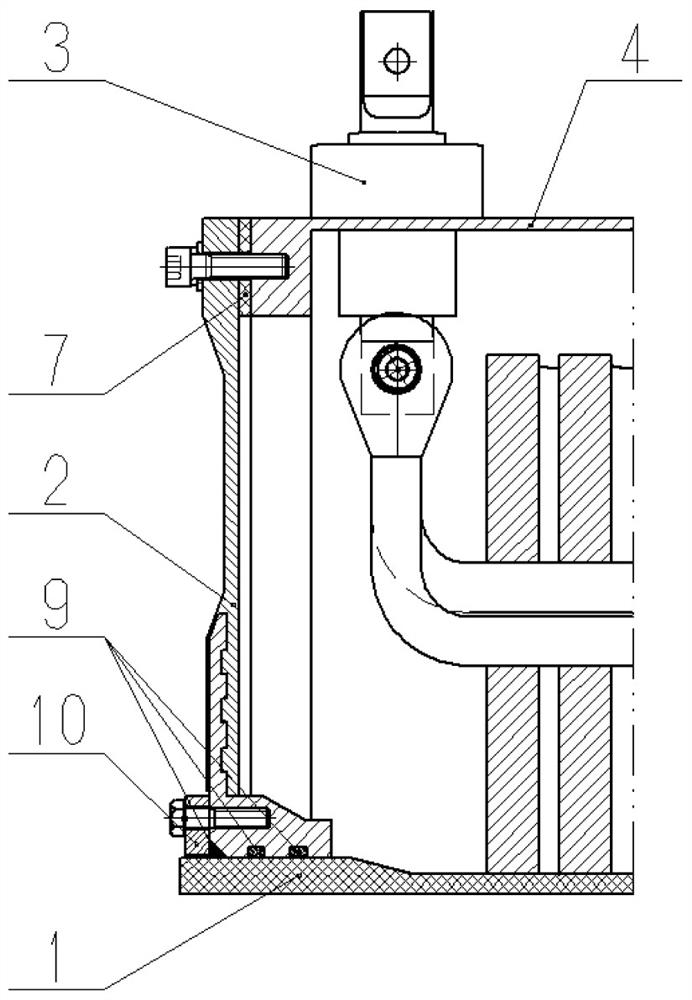

[0054] The invention discloses a liquid-cooled air-gap armature stator structure for a high-temperature superconducting motor. Cap 6, rubber backing plate 7, non-outlet end plate 8 and sealing ring 9; the cylinder 1 is axially inserted into the inner cavity of the stator armature 5, and the cylinder 1 is a ring with thick walls at both ends and a thin wall in the middle Shaped structure, made of glass fiber winding; the cylinder 1 is also set with the outlet end cap 4 and the non-exit end cap 6 respectively, and the outlet end cap 4 and the non-exit end cap 6 pass through the sealing ring 9 and the The bolts are sealed with the end face of the stator armature 5, the outlet end cap 4 is provided with a cooling liquid pipeline 43 and a sealing terminal 3, the cooling liquid pipeline 43 is connected to the external cooling system, the outlet end cap 4 and the non-outlet end end The outside of the ...

Embodiment 2

[0069] The invention also discloses an assembly method for the liquid-cooled air-gap armature stator structure of the high-temperature superconducting motor, the steps of which are:

[0070] Step 1, respectively process the outlet end cap 4, the outlet end plate 2, the non-outline end cap 6, the non-outline end plate 8, the cylinder 1 and the stator armature 5, wherein the cylinder 1 has an adjustable Metal inner membrane, used to maintain and adjust the roundness.

[0071] Step 2, clean the sealing surface with alcohol or acetone, and connect the end cap 4 of the outlet end and the end cap 6 of the non-outlet end to the stator armature respectively through the sealing ring 9 and the bolts for end face sealing connection.

[0072] Step 3, place the stator armature 5 installed with the end cap 4 of the outgoing end and the end cap 6 of the non-exiting end vertically on the tooling, wherein the outgoing end faces upward.

[0073] Step 4, insert the cylinder 1 with the metal inn...

Embodiment 3

[0084] The difference from Embodiment 1 is that: the composite material of the end plate 2 at the outlet end and the end plate 8 at the non-outlet end is aramid fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com