Chiral cinchona alkaloid-squaramide catalyst (CSF-MSNs) loaded on inorganic meso-porous silicon and preparation thereof

A technology of chiral square amide and cinchona base, which is applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc., and can solve problems such as high price, difficult product separation, and pollution , to achieve strong activity, high thermodynamic stability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

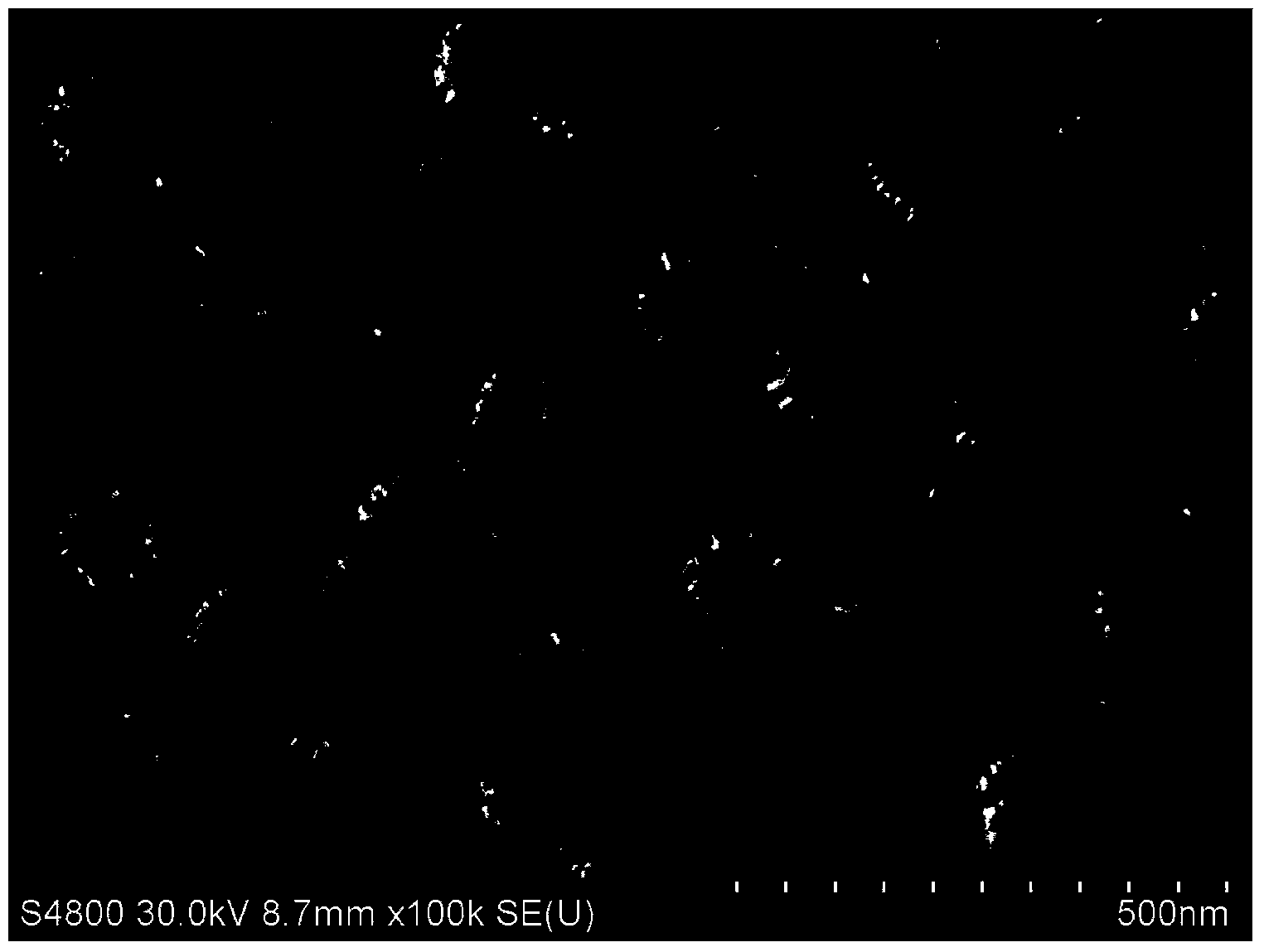

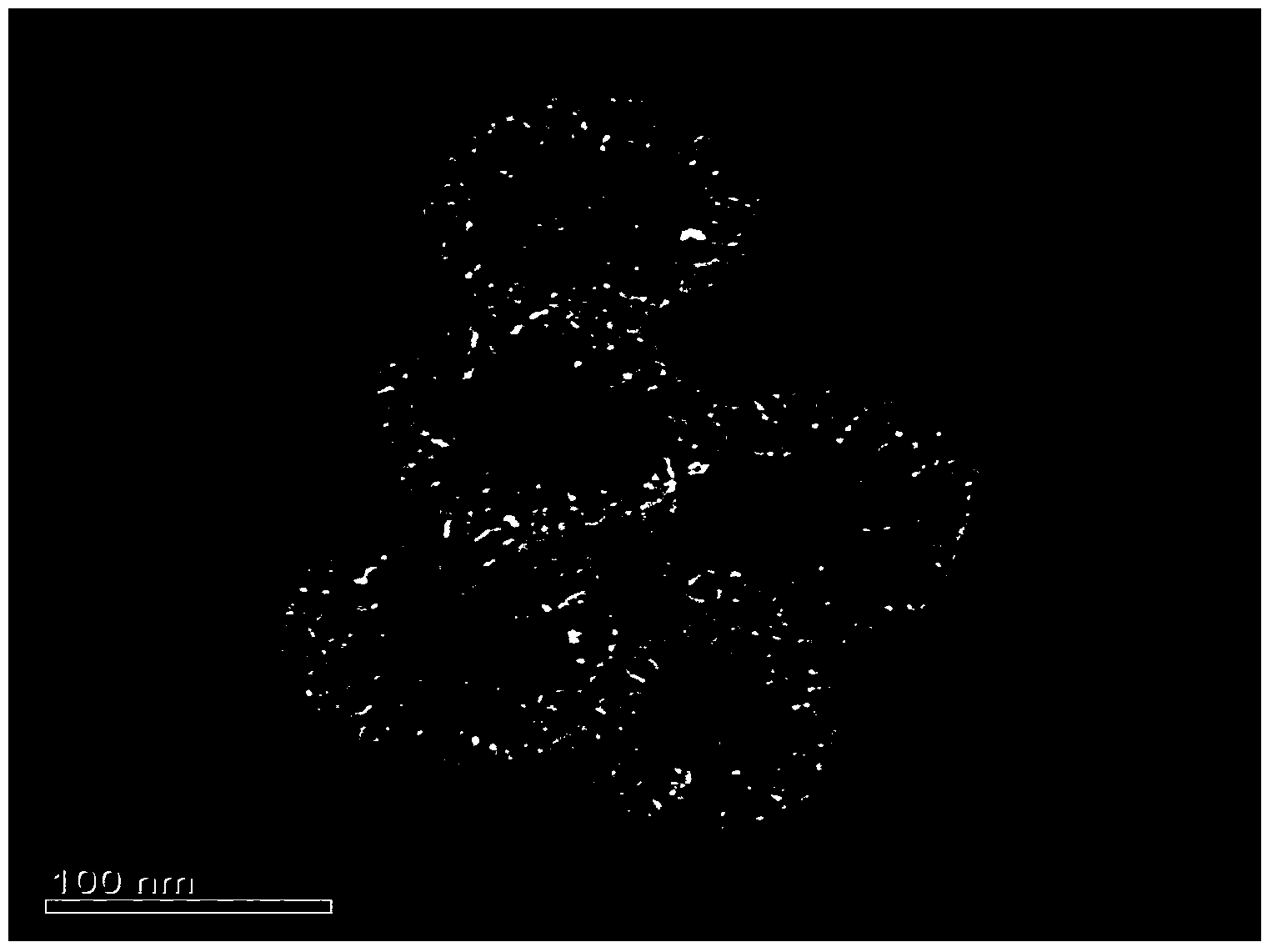

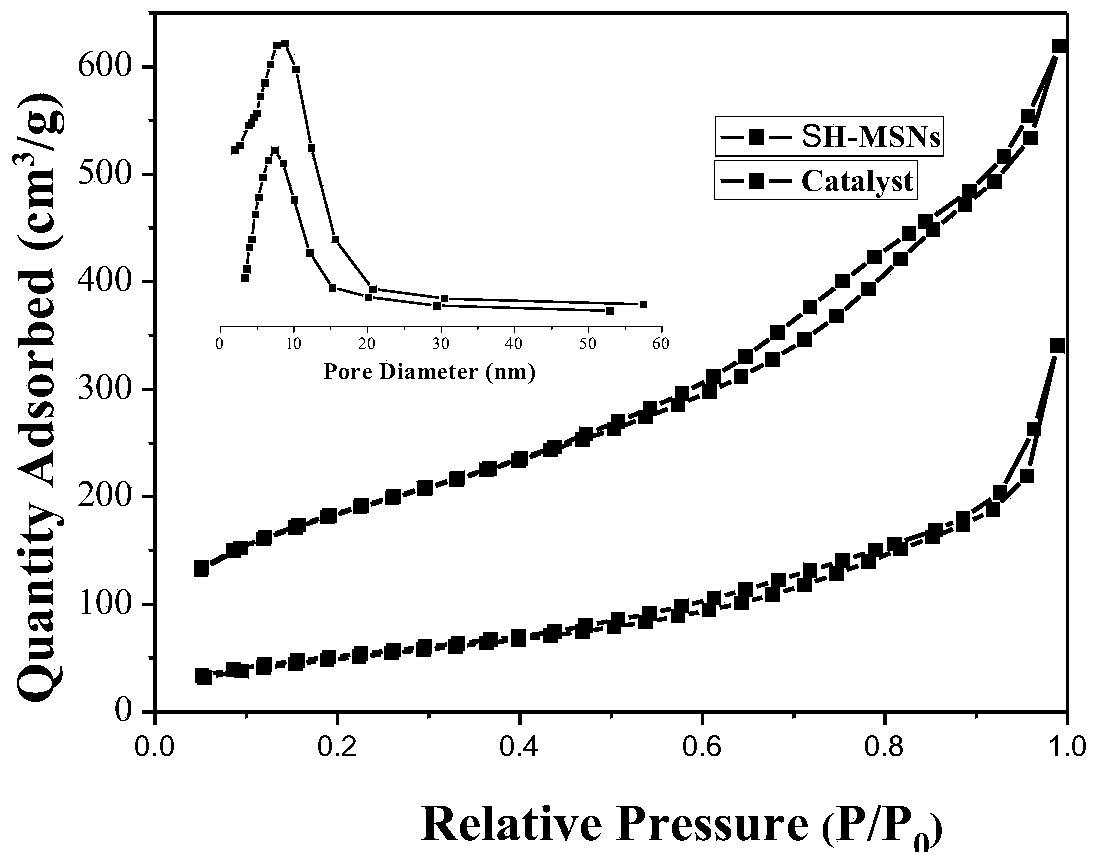

[0026] (1) Synthesis of thiol-functionalized carrier SH-MSNs

[0027] Get a 200mL three-necked flask, add 1.92g of cetrimonium tosylate (CTATos), 0.35g of triethanolamine (TEAH 3 ) and 100mL deionized water, mechanically stirred at 80°C for 1h;

[0028] Quickly add 14.58g of tetraethyl orthosilicate (TEOS), then in the process of stirring, dropwise add 1.19g of γ-mercaptopropyltrimethoxysilane (MPTMS) with a disposable dropper, and control the dropping within 5 minutes , the reaction continued to be mechanically stirred at a speed of 1200r / min at 80°C for 2h;

[0029] After the reaction, filter with suction, wash, and then dry in a vacuum oven at 100° C. for 20 h. Then it was ground and extracted in alcoholic hydrochloric acid solution and aqueous hydrochloric acid solution at 80°C for 24 hours respectively to obtain white powdery solid SH-MSNs.

[0030] (2) Synthesis of chiral square amide homogeneous catalyst:

[0031] In a 10mL round bottom flask, add 127mg (0.36mmol) o...

Embodiment 2

[0039] (1) Synthesis of thiol-functionalized carrier SH-MSNs

[0040] Take a 250mL three-necked flask, add 3.84g of cetrimonium p-toluenesulfonate (CTATos), 0.70g of triethanolamine (TEAH3) and 200mL of deionized water, and mechanically stir at 80°C for 1h;

[0041] Quickly add 29.16g of tetraethyl orthosilicate (TEOS), and then add 2.38g of γ-mercaptopropyltrimethoxysilane (MPTMS) dropwise with a disposable dropper during stirring, and control the dropping within 5 minutes , the reaction continued to be mechanically stirred at a speed of 1200r / min at 80°C for 2h;

[0042]After the reaction, filter with suction, wash, and then dry in a vacuum oven at 100° C. for 20 h. Then it was ground and extracted in alcoholic hydrochloric acid solution and aqueous hydrochloric acid solution at 80°C for 24 hours respectively to obtain white powdery solid SH-MSNs.

[0043] (2) Synthesis of chiral square amide homogeneous catalyst:

[0044] In a 10mL round bottom flask, add 127mg (0.36mmol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com