A method for complete combustion of heavy components of bio-oil at low temperature using cu-mn-based supported monolithic catalysts

A monolithic catalyst and heavy component technology, applied in the direction of combustion using catalytic materials, combustion methods, molecular sieve catalysts, etc., can solve the problems of high cost of precious metals, deactivation of activity, easy reduction of catalytic activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

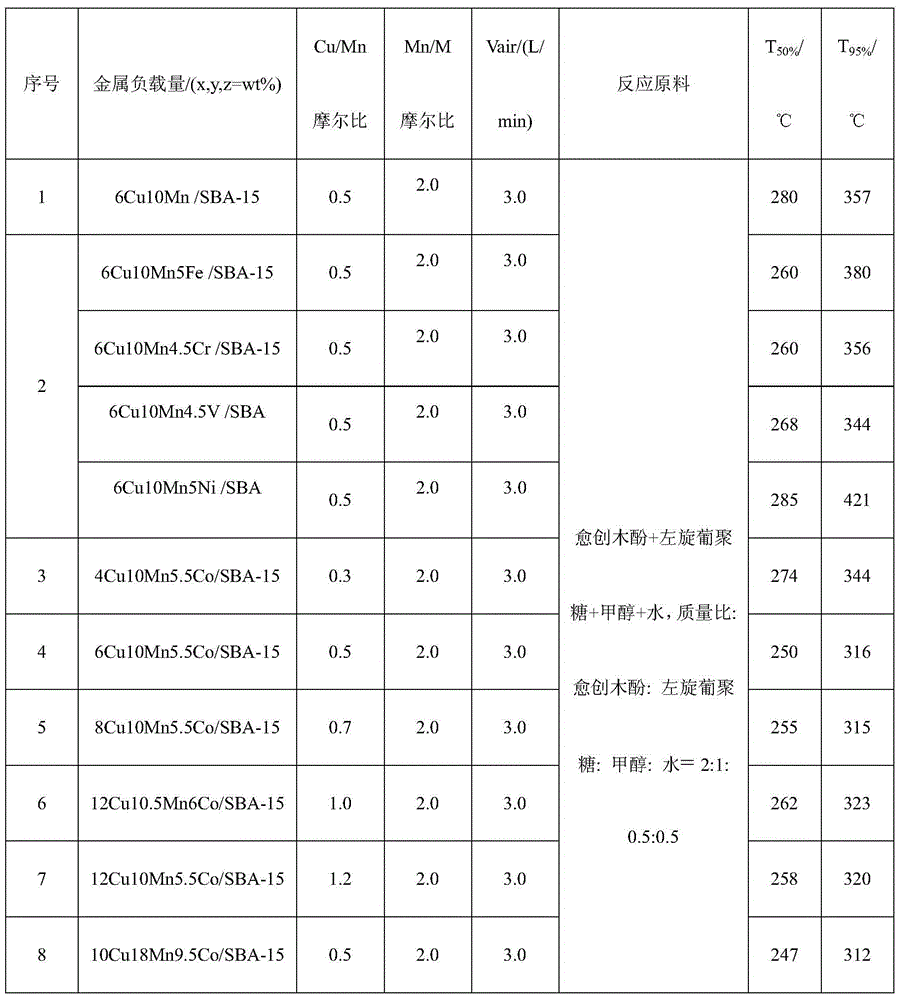

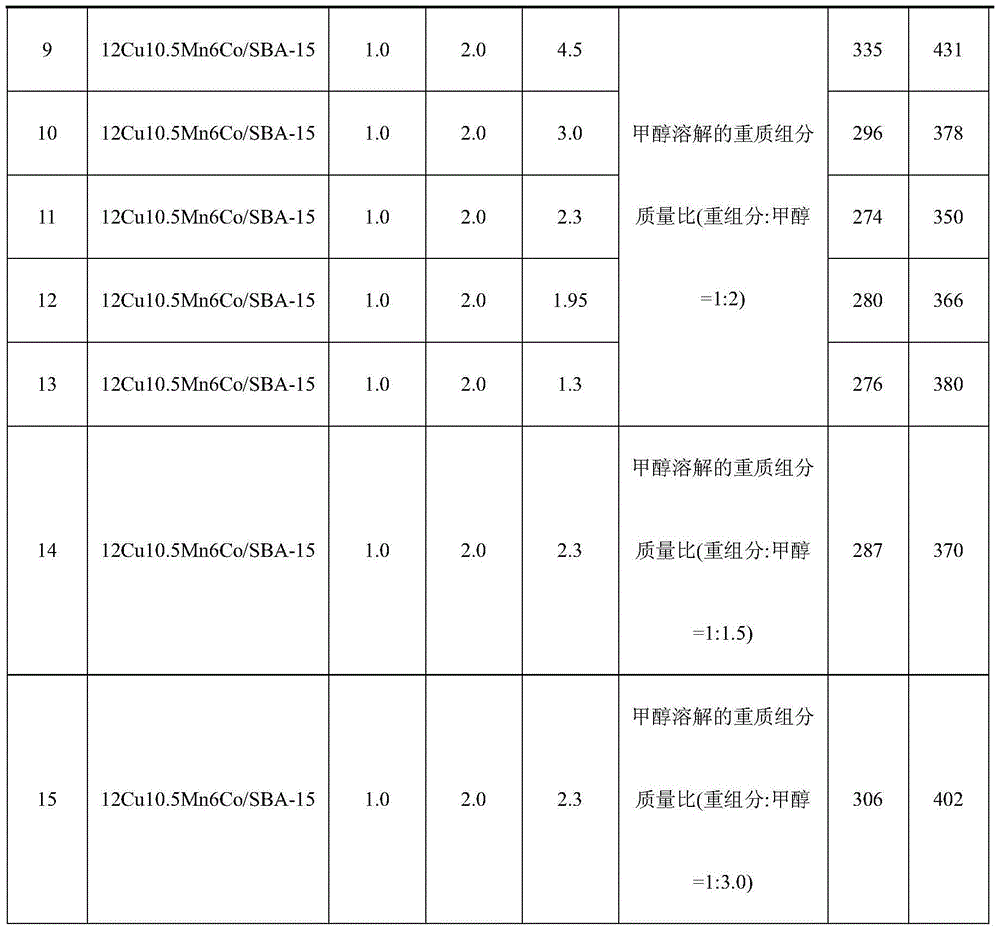

[0025] Embodiment 1: 6Cu10Mn (wt%) / SBA-15 catalyst preparation and its combustion model mixture performance experiment

[0026] (1) Preparation of SBA-15 mesoporous molecular sieve carrier by hydrothermal synthesis: 3.65-4.0 g of triblock surfactant P 123 (Aldrich, EO 20 PO 70 EO 20 , with a molecular weight of 5800) was dissolved in 80-95g deionized water, and then 3.0-4mol / L HCl solution and tetraethylorthosilicate (TEOS) were added; P 123 , HCl, H 2 O. The mass ratio of TEOS is 1:1.5~2.0:36.10:2.13, stir vigorously for 24h, transfer the mixed solution to a Teflon bottle after the reaction, crystallize at 90~110°C for 1~2d, then filter, Washing and drying, the resulting product is calcined at 500-650°C for 4-6 hours to remove the template agent to obtain a surface area of about 650-720m 3 / g, SBA-15 mesoporous molecular sieve white powder with a pore size of 5-10nm.

[0027] (2) Preparation of 6Cu10Mn / SBA-15 catalyst by ethylene glycol dispersion-ultrasonic assisted ...

Embodiment 2、6

[0030] Embodiment 2, 6Cu10MnzM / SBA-15 catalyst preparation and performance experiment

[0031] (1) with (1) in the embodiment 1 method;

[0032] (2) Preparation of 6Cu10MnzM / SBA-15 catalyst by ethylene glycol dispersion-ultrasonic assisted equal volume impregnation method: Cu(NO 3 ) 2 ·3H 2 O and 50% Mn(NO 3 ) 2 (Molar ratio Cu / Mn=0.5, Mn / M=2.0) and the nitrate of M (Co, V, Cr, Fe, Ni etc.) are dissolved in the mixed solution of water and ethylene glycol (wherein, mass ratio m SBA-15 :m 水 =1:3.5~5, the molar ratio of active metal to ethylene glycol is 1.0~5.0:1), then add 3g (the mass ratio of active metal to SBA-15 mesoporous molecular sieve is 16~37.5%) step (1) preparation The SBA-15 is stirred evenly, placed under ultrasonic conditions for 0.5-2 hours to form a uniform suspension, and then dried at 80-100°C for 5-8 hours. After grinding, the temperature is programmed to rise to 450-650°C and calcined for 4-6 hours to obtain 6Cu10MnzM / SBA-15 catalyst.

[0033] (3) P...

Embodiment 3、4

[0035] Embodiment 3, 4Cu10Mn5.5Co / SBA-15 catalytic combustion model mixture performance experiment

[0036] (1) 4Cu10Mn5.5Co / SBA-15 is prepared with (1)~(3) in the embodiment 1 method;

[0037] (2) Catalyst activity evaluation is the same as (4) in the embodiment 1 method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com