Preparation method of copper and ferrum composite catalyst loaded on aluminum surface

A composite catalyst, aluminum surface technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Expensive, unsuitable for industry, etc., to achieve the effect of easy recycling, low cost, and efficient catalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

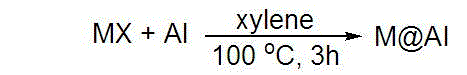

Method used

Image

Examples

Embodiment 1

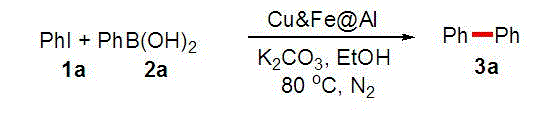

[0017] Plating solution preparation: Dissolve 3.8 mg of ferric chloride and 4.3 mg of copper chloride in xylene to form a 15 ml plating solution.

[0018] Preparation method: under the protection of nitrogen, put 5 pieces of metal aluminum foil (each with a length of 1 cm and a width of 1 cm) in 15 ml of the above-mentioned plating solution, and heat for 3 hours at the temperature of the plating solution at 100°C After cooling. After cooling, the aluminum foil is taken out, washed successively with ethanol and deionized water, and a clean copper-iron composite solid sheet loaded on the surface of the aluminum foil is obtained.

[0019] Place 61 mg of phenylboronic acid (0.5 mmol), 138 mg of potassium carbonate (1.0 mmol), 102 mg of iodobenzene (0.5 mmol) and the above sheet in 2 mL of ethanol, and react at the temperature of the mixture at 80°C . The reaction was monitored by thin layer chromatography. After the reaction, the catalyst was taken out (it can be directly appli...

Embodiment 2

[0021] Other conditions are the same as in Example 1, the catalyst is recovered, and the recycling efficiency of the catalyst is checked. The experimental results are shown in Table 1.

[0022] Table 1 Catalyst recycling efficiency test

[0023]

[0024] Cycles 1 2 3 4 5 6 7 Yield / % 93 91 87 80 72 60 54

[0025] As can be seen from the above, the catalyst can be conveniently recycled for many times while maintaining activity.

Embodiment 3

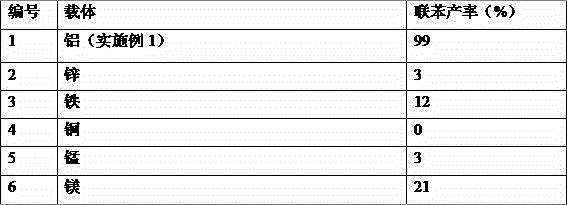

[0027] Other conditions were the same as in Example 1, and the catalyst activity of different carriers was tested by using zinc flakes, iron flakes, copper flakes, manganese flakes, and magnesium flakes respectively, and the experimental results are shown in Table 2.

[0028] Table 2 Test of activity of catalysts with different supports

[0029]

[0030] From the above, it can be seen that only aluminum as a carrier (Example 1) can prepare a catalyst with high catalytic activity. Other metals cannot be used as carriers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com