Polymer film with antifouling and anti-bacterial functions and preparation method of polymer film

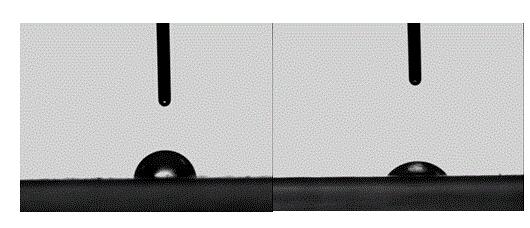

A polymer membrane, polymer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as trouble, invasion and pollution, achieve good anti-fouling effect, super anti-organic pollution performance and The effect of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

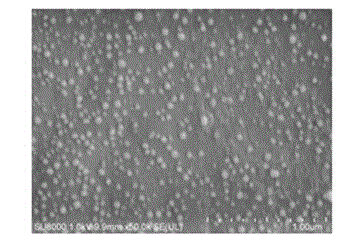

[0078] Preparation of PVDF Flat Membrane with Antifouling and Antibacterial Function

[0079] 1. Preparation of silver-containing nanoparticles

[0080] 1 g of silica nanoparticles was ultrasonically dispersed into 50 ml of ethanol, 0.1 g of mercaptopropyltrimethoxysilane was added, and the reaction was refluxed at 80 °C for 5 h. Subsequently, 10 ml of 0.1 mM silver nitrate solution was added and reacted for 2 h. Then add 5 ml of 0.1 M sodium borohydride solution to the solution system and fully react for 1 h. The modified nanoparticles were collected by centrifugation for later use.

[0081] 2. Preparation of polymer films

[0082] Disperse 1 g of modified nanoparticles into 74 g of DMAC, add 25 g of PVDF and 5 g of PEG, and use a high-speed mechanical stirrer to stir and dissolve at a rate of 12000 r / min for 30 min to obtain a casting solution; After the membrane solution was vacuum degassed for 6 hours, the casting solution was directly scraped onto the support net to...

Embodiment 2

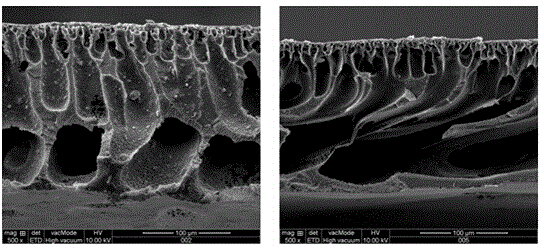

[0093] Preparation of PVDF hollow fiber membrane with antifouling and antibacterial functions

[0094] 1. Preparation of silver-containing nanoparticles

[0095] Ultrasonic dispersion of 1 g of titanium dioxide nanoparticles into 50 ml of ethanol solution was added with 0.5 g of mercaptopropyltrimethoxysilane, and the reaction was refluxed at 80 °C for 10 h. Subsequently, 50 ml of 0.1 mM silver nitrate solution was added and reacted for 5 h. Then add 20 ml of 0.1 M sodium borohydride solution to the solution system and fully react for 4 h. The modified nanoparticles were collected by centrifugation for later use.

[0096] 2. Preparation of polymer films

[0097] Disperse 0.1 g of modified nanoparticles into 80 g of NMP, add 15 g of PVDF and 5 g of PEG, and use a high-speed mechanical stirrer to stir and dissolve for 20 min at a rate of 10,000 r / min to obtain a casting solution; After 8 hours of vacuum degassing treatment, the casting solution was put into the spinning ke...

Embodiment 3

[0103] Preparation of PAN Flat Film with Antifouling and Antibacterial Function

[0104] 1. Preparation of silver-containing nanoparticles

[0105] 1 g of hydroxylated carbon nanotubes was ultrasonically dispersed into 50 ml of ethanol, 0.3 g of mercaptopropyltrimethoxysilane was added, and the reaction was refluxed at 80 °C for 10 h. Then add 30 ml of 0.1 mM silver nitrate solution and react for 4 h; then add 15 ml of 0.1 M sodium borohydride solution to the solution system and fully react for 3 h. By centrifugation, the modified hydroxylated carbon nanotubes are collected for use.

[0106] 2. Preparation of polymer films

[0107] Disperse 2 g of modified hydroxylated carbon nanotubes into 60 g of DMF, add 18 g of PAN and 10 g of PVP, and use a high-speed mechanical stirrer to stir and dissolve at a rate of 12000 r / min for 30 min to obtain a cast film liquid; after 7 hours of vacuum defoaming treatment on the casting solution, the casting solution was directly scraped to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com