igbt half bridge inverter intermediate frequency - super audio frequency - high frequency induction heating power supply

A high-frequency induction heating, half-bridge inverter technology, applied in induction heating, induction current source, induction heating control and other directions, can solve the problem of limited use range, achieve high power factor, friendly man-machine interface, high efficiency system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

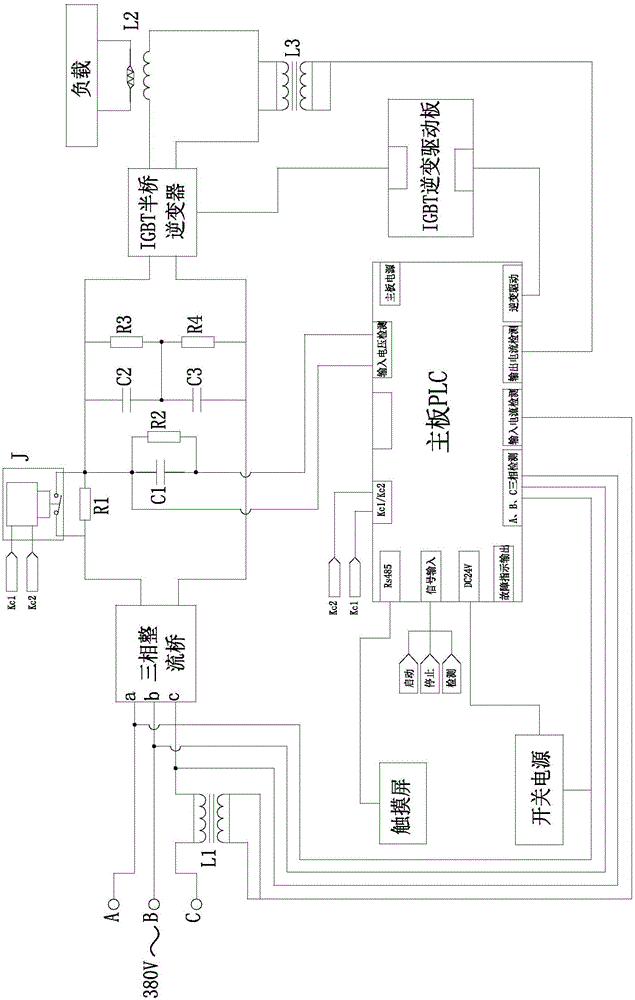

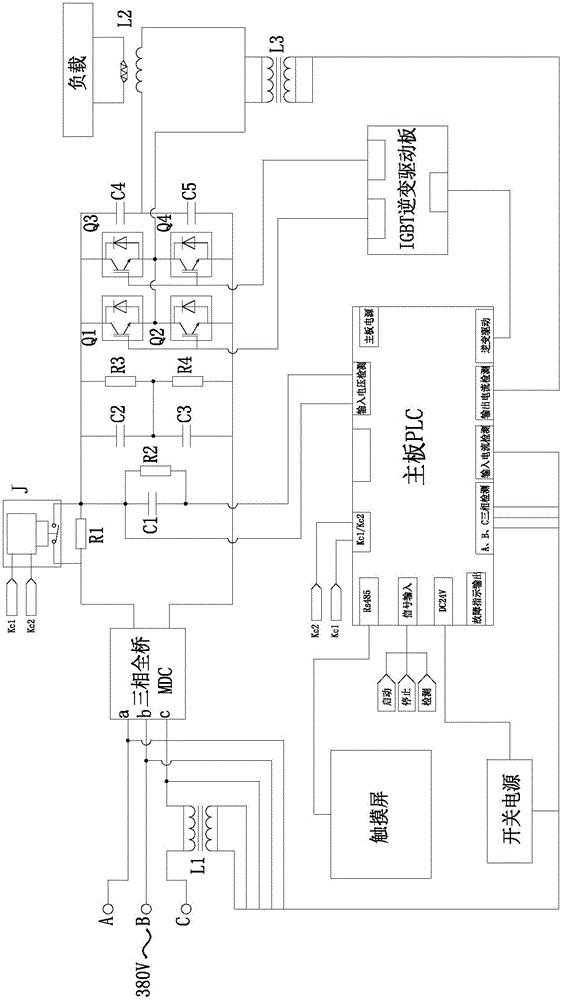

[0009] Such as figure 1 , figure 2 As shown, an IGBT half-bridge inverter intermediate frequency-super audio-high frequency induction heating power supply includes: a three-phase rectifier bridge, an IGBT inverter drive, an IGBT half-bridge inverter, and the IGBT half-bridge inverter main board PLC consists of two Block IC completes relevant functions (IC1: EPM240T100C5N and IC2: TMS320LF2407ApGEA), touch screen, switching power supply; three-phase power supply A, B, C are connected to terminals A, B, and C of the three-phase rectifier bridge, and the three-phase rectifier bridge is connected to the IGBT half-bridge inverter , between the three-phase rectifier bridge and the IGBT half-bridge inverter are connected with a pre-charging resistor R1, a charging relay coil J, a filter circuit and a resistance-capacitance absorption circuit, and the filter circuit is composed of a parallel filter capacitor C1 and a discharge resistor R2 , the resistance-capacitance absorbing loop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com