Engine control mechanism

A control mechanism and engine technology, applied in the direction of engine control, electric engine control automatic control, automatic control, etc., can solve the problems of delay, limited maneuverability, low discharge pressure of oil pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Figure 7 It is an explanatory diagram showing how each part changes when the operating state of the engine E is a transitional operating state.

[0063] Figure 7(1) Accelerator opening degree, (2) Intake valve opening degree, (3) Ignition timing, (4) Exhaust side VVT phase, (5) Intercooler outlet boost pressure, (6) ) front-rear acceleration of the vehicle, (7) intake side VVT phase, (8) engine load, and (9) engine speed. In the figure, a solid line indicates an example of engine control according to the present embodiment, and a dashed-dotted line indicates an example of engine control capable of realizing the Atkinson cycle operation of the related art.

[0064] Even though the engine is transitioning from the Atkinson cycle state to the high output state, it is not assumed in this paper that the accelerator is heavily depressed. Conversely, the engine control mechanism is effective when overrunning from the low-load Atkinson operating range where practical f...

Embodiment approach

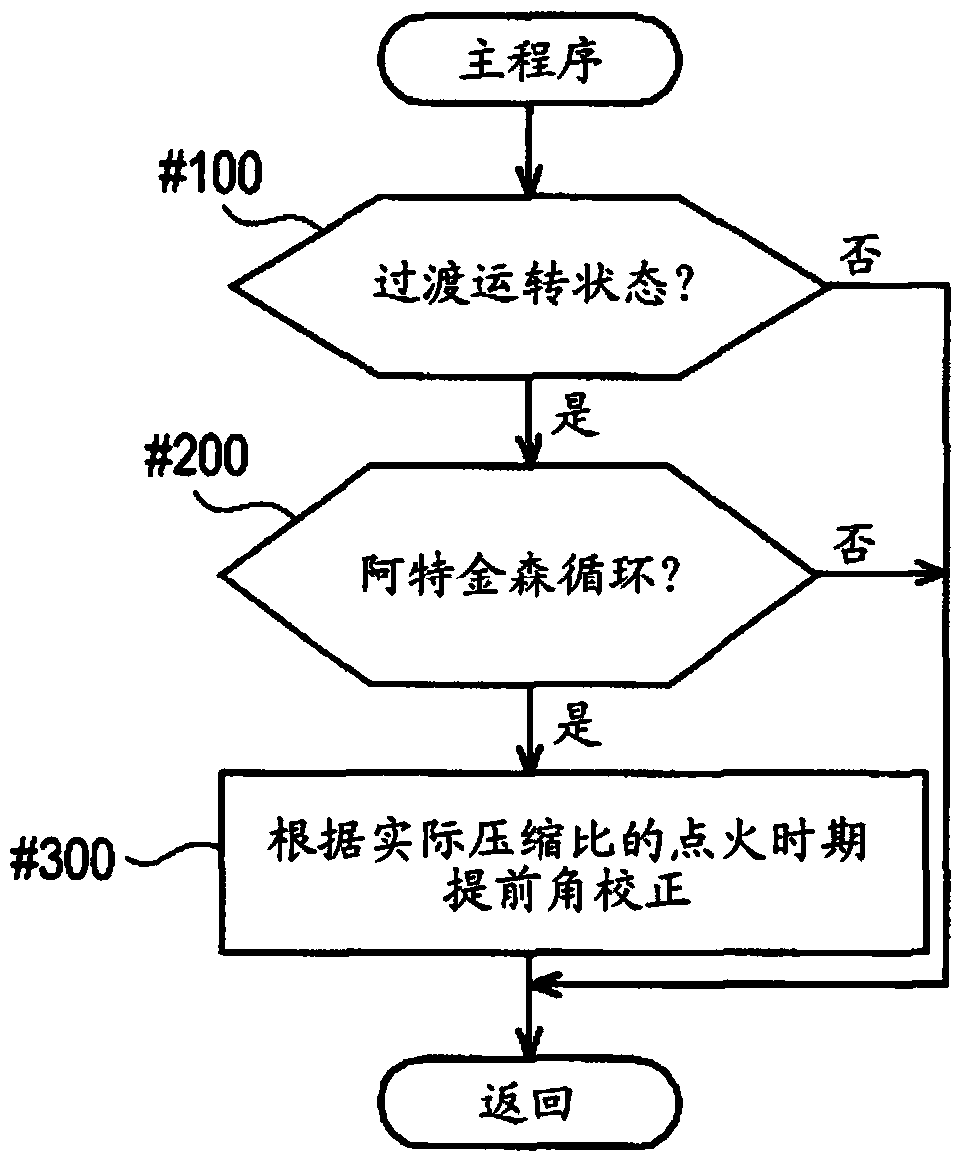

[0075] The ignition timing advance angle correction control, VVT hydraulic oil pressure boost correction control, and exhaust side VVT 5 advance angle correction control described in the above-mentioned embodiments are as follows: Image 6 The illustration can also be constituted by a flowchart. For example, after the transient operation determination (step 130) and the Atkinson cycle determination (step 230) by the ECU 6a, the ignition timing advance angle correction (step 330) and the determination of whether the actual VVT phase has reached the target VVT phase are performed (step 430); when the actual VVT phase is less than the target VVT phase, perform boost correction of VVT hydraulic oil pressure (step 530), and determine whether the actual supercharging pressure reaches the target supercharging pressure (step 630); The advance angle correction of the exhaust side VVT 5 is performed when the actual supercharging pressure is smaller than the target supercharging pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com