A kind of chemical polishing agent and its application

A technology of chemical polishing and catalyst, which is applied in the field of chemical polishing agent and its application, can solve the problems such as the temperature rise of polishing liquid, the damage of inorganic acid to the human body, and the impact on the service life of polishing liquid, so as to achieve the reduction of decomposition rate, wide application range, and improvement The effect of polishing speed and rust removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preparation method of chemical polishing agent:

[0020] Weigh successively water, catalyst at normal temperature and stir to dissolve transparently according to parts by weight, under the condition of continuous stirring, successively weigh acidic rust removal mixture, complexing agent, corrosion inhibitor, leveling and brightening agent, stir and compound evenly, until it dissolves completely evenly, Form a rust-removing brightener;

[0021] Weighing water and polishing stabilizer in order according to parts by weight, stirring and mixing uniformly at room temperature, adding an oxidizing agent under continuous stirring conditions, to obtain a polishing additive;

[0022] Mix the above-mentioned rust-removing brightener and polishing additive in order, and after stirring evenly, the finished chemical polishing agent is obtained.

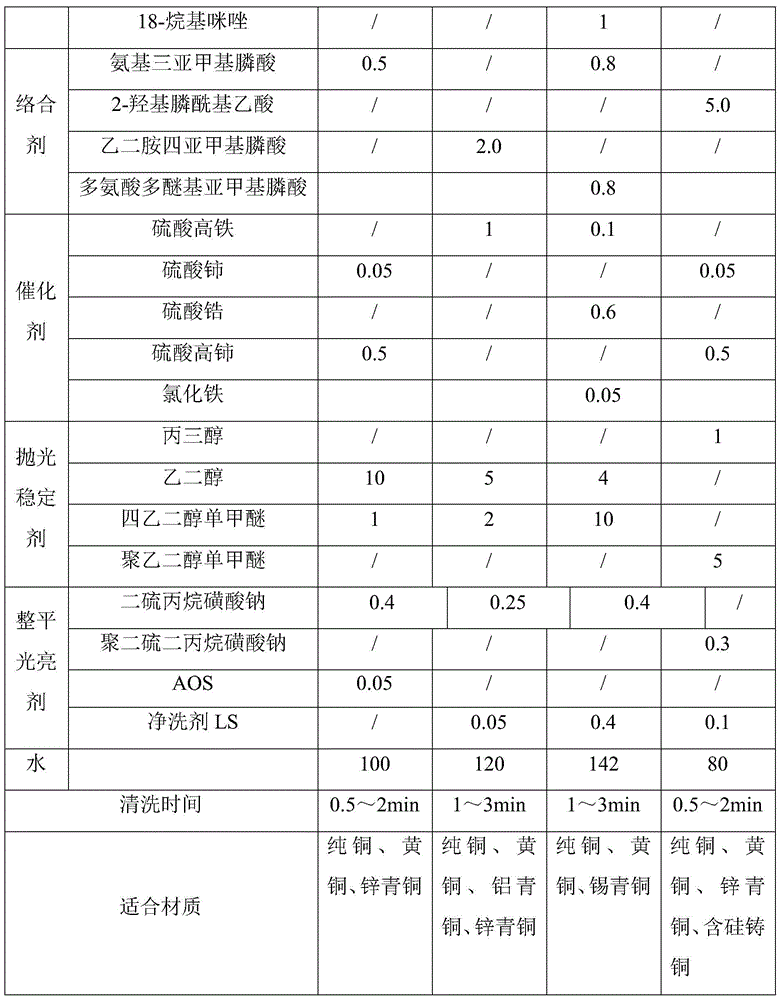

Embodiment 1--4

[0024] Table 1: Examples 1-4

[0025]

[0026]

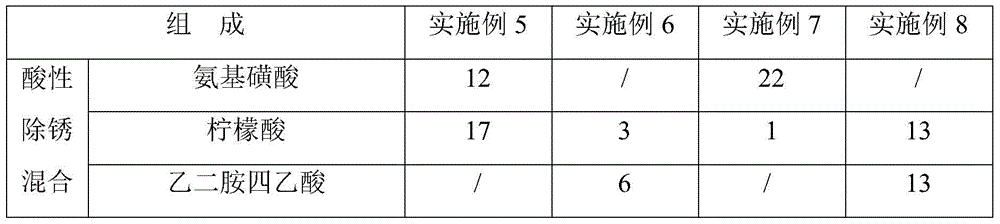

Embodiment 5--8

[0028] Table 2: Examples 5-8

[0029]

[0030]

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com