Preparation method of solvent-free water-based polyurethane resin

A water-based polyurethane and solvent-free technology, applied in the field of polymer materials, can solve problems such as unfavorable environments, achieve the effects of improving compatibility and adhesion, avoiding excessive viscosity of materials, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

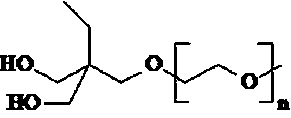

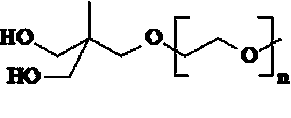

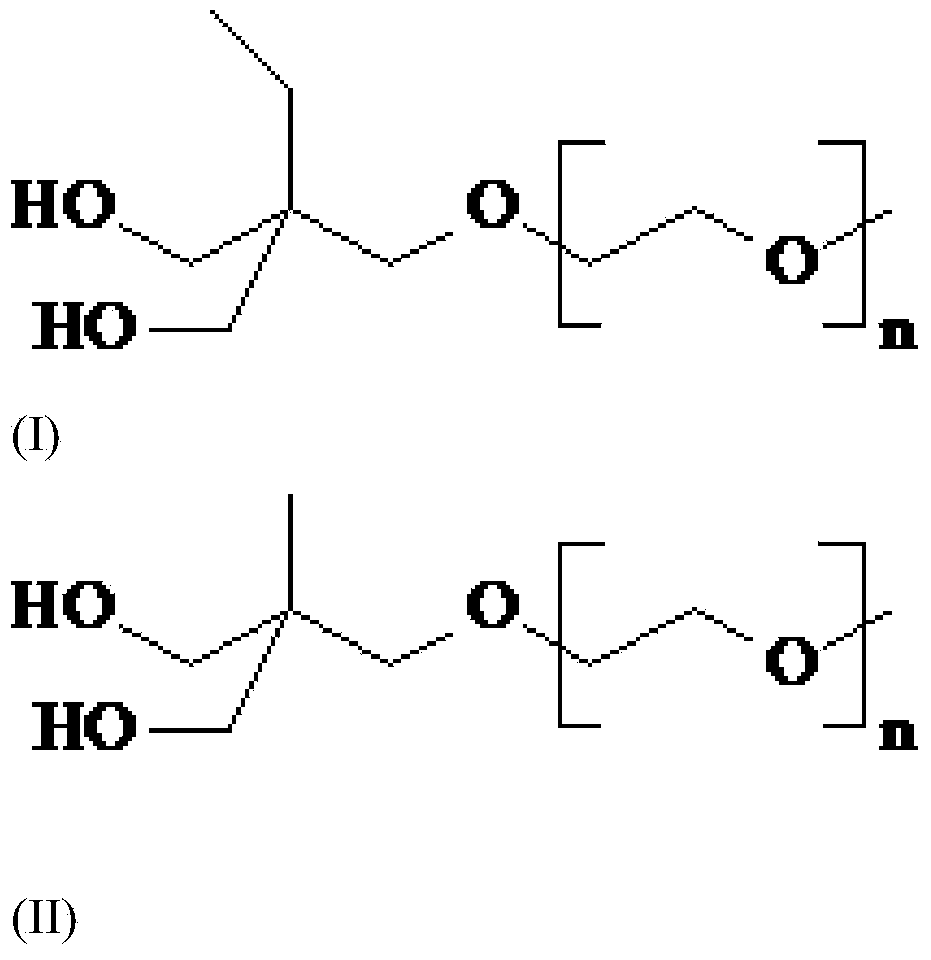

Method used

Image

Examples

Embodiment 1~5

[0043] The raw materials and proportioning ratios used in the following examples are shown in Table 1.

[0044] Table 1 embodiment 1~5 and comparative example 1~3 reaction condition and parameter (unit: g)

[0045]

[0046]

[0047] Preparation:

[0048] After mixing polyisocyanate, amino-type cage silsesquioxane, polyol, ethoxy-terminated polymer diol, hydrophilic monomer, and catalyst di-n-butyltin dilaurate, proceed at 50-110°C The prepolymerization reaction takes 2 to 4 hours to obtain a polyurethane prepolymer. Add neutralizer and water to the polyurethane prepolymer at room temperature for forced dispersion, then add chain extender at 30-50°C for chain extension reaction for 2-4 hours, then cool down to room temperature to obtain water-based polyurethane.

[0049] Performance tests were carried out on the water-based polyurethanes prepared in the above examples and comparative examples, and the specific results are shown in Table 2.

[0050] The performance test...

Embodiment 6

[0054] The amount of ethoxy-terminated polymer diol was varied in this example.

[0055] A kind of preparation method of solvent-free aqueous polyurethane resin, comprises the steps:

[0056] Step 1, 200g of toluene diisocyanate, 10g of aminopropyl cage silsesquioxane T8, 50g of ethylene glycol, 2,2-dimethylol butoxyethylene glycol (20EO) methyl ether, two 40g of methylolpropionic acid and 1g of catalyst were mixed evenly, and the temperature was raised to 100°C for prepolymerization / 2h to obtain a polyurethane prepolymer;

[0057] Step 2: Add 1g of ammonia water and 550g of water to the polyurethane prepolymer, disperse evenly, then add 20g of 1,4-butanediamine to carry out chain extension reaction, temperature is 50°C, time is 3h, and it is lowered to room temperature to obtain waterborne polyurethane .

[0058] The performance data of the waterborne polyurethane prepared in this embodiment are shown in Table 3.

[0059] The performance data of different ethoxy-terminated...

Embodiment 7

[0063] In this example, alkyd resin-modified polyisocyanate is used. The modification method is: mix 30 g of cottonseed oil and 4 g of glycerin evenly, heat up to 120 ° C, add 0.1 g of KOH catalyst, react at 200 ° C for 2 hours, and cool down Finally, add 3g of benzoic acid and react at 180°C for 2h. When the temperature is lowered to 40°C, add 30g of toluene diisocyanate and 20g of xylene, raise the temperature to 65°C and keep it for 2h. After cooling down to room temperature, filter to obtain the modified alkyd resin non-toxic polyisocyanate. It is used in the preparation of waterborne polyurethane.

[0064] The 1st step, with alkyd resin modified toluene diisocyanate 200g, aminopropyl cage type silsesquioxane T8 10g, ethylene glycol 50g part, 2,2-dimethylol butoxyethylene glycol ( 20EO) 60g of methyl ether, 40g of dimethylolpropionic acid, and 1g of catalyst were mixed evenly, and the temperature was raised to 100°C for prepolymerization / 2h to obtain a polyurethane prepol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com