Preparation method of waterborne polyurethane resin

A technology of water-based polyurethane and polyurethane prepolymer, which is applied in the field of polymer material manufacturing, can solve problems such as low strength and general wear resistance, and achieve the effects of increasing strength, improving compatibility and cohesive force, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

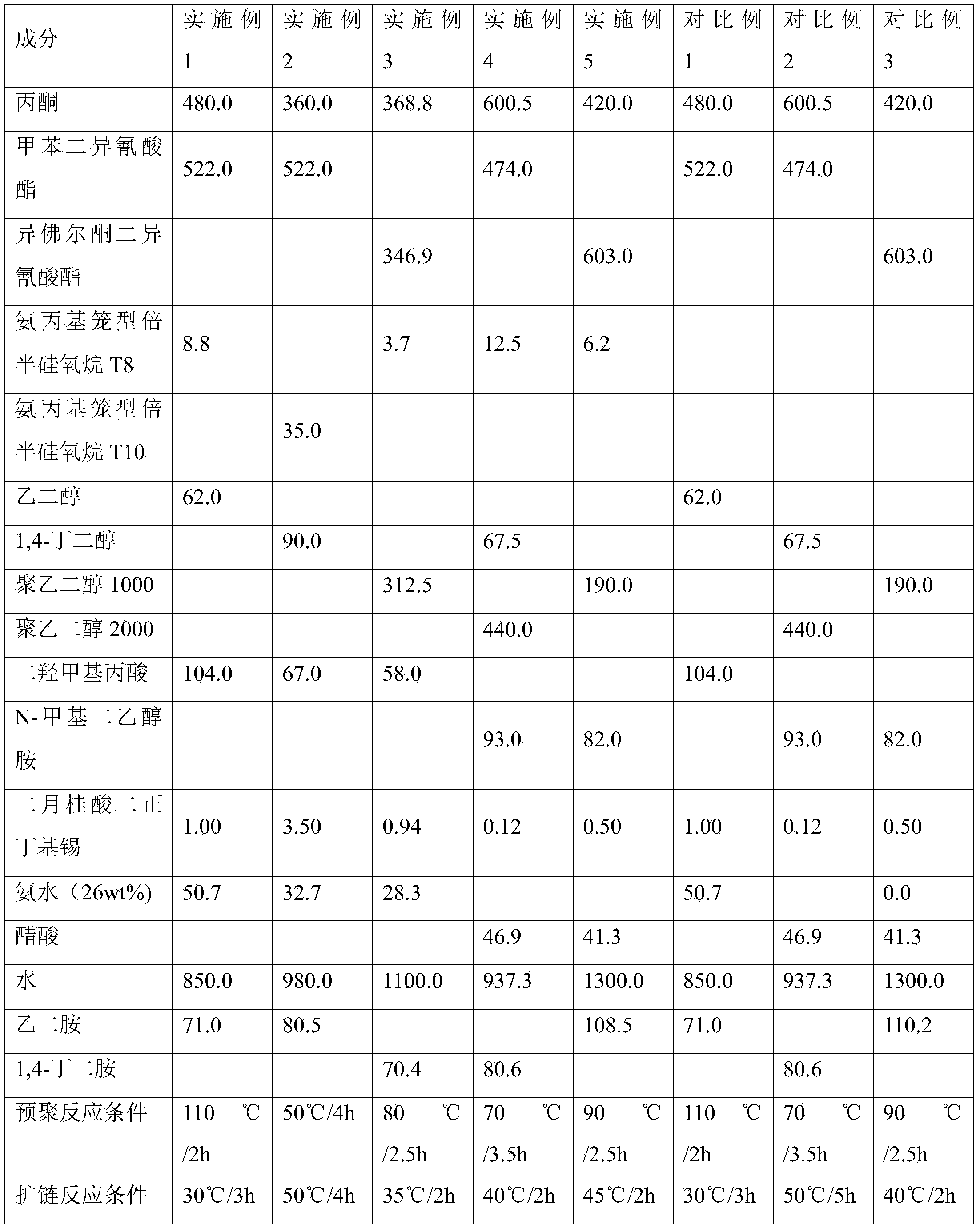

Examples

Embodiment 6

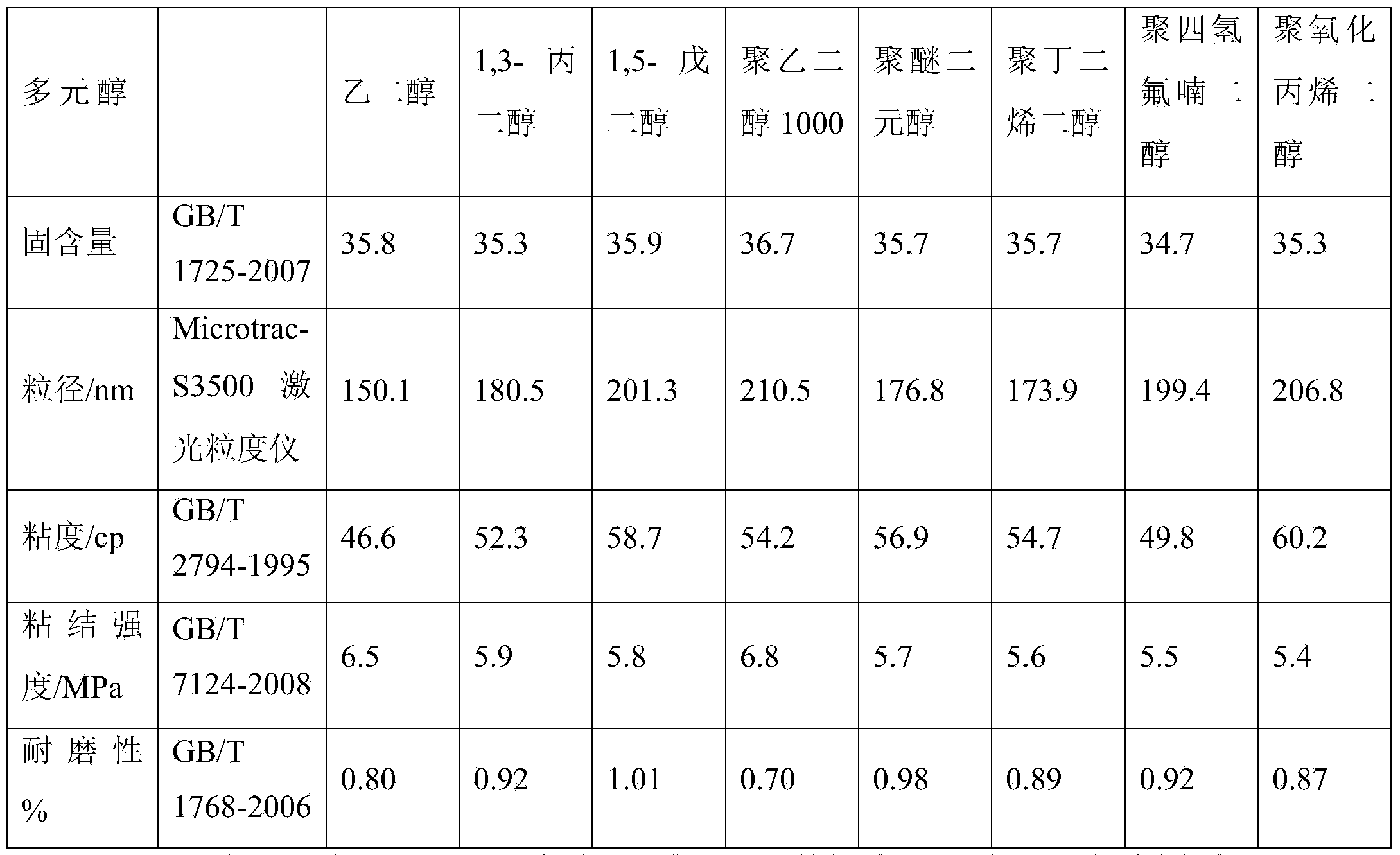

[0043] Different polyols were used in this example.

[0044] (1) Acetone 480.0g, toluene diisocyanate 522.0g, aminopropyl cage silsesquioxane T88.8g, polyol 62.0g, dimethylol propionic acid 104.0g, catalyst di-n-butyltin dilaurate 1.00 After mixing evenly, carry out prepolymerization reaction at 50-110°C for 2 hours to obtain polyurethane prepolymer.

[0045] (2) Add 50.7g of ammonia water (26wt%) to the polyurethane prepolymer at room temperature, then add 850.0g of water to disperse, and then add 71.0g of chain extender ethylenediamine at 30°C to carry out the chain extension reaction for 3 hours. At room temperature, water-based polyurethane is obtained.

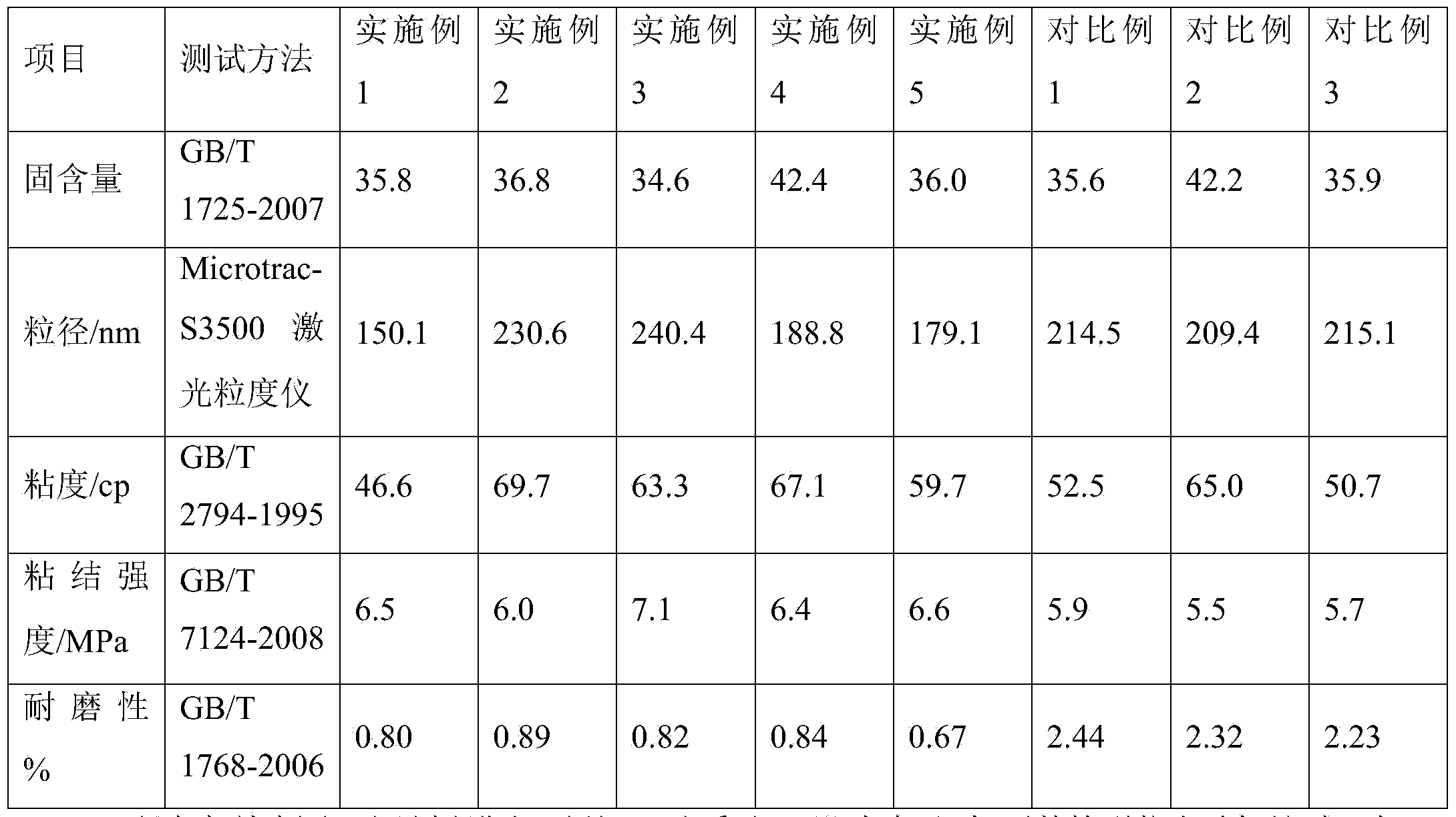

[0046] The performance data of the prepared water-based polyurethane are shown in Table 3:

[0047] Table 3 Performance data of waterborne polyurethane

[0048]

[0049] It can be seen from Table 3 that when different polyols are used as polymerized monomers, the problem of improving wear resistance can be solved.

Embodiment 7

[0051] Different hydrophilic monomers were used in this example.

[0052] (1) Acetone 480.0g, toluene diisocyanate 522.0g, aminopropyl cage silsesquioxane T88.8g, polyethylene glycol 100062.0g, hydrophilic monomer 104.0g, catalyst di-n-butyltin dilaurate After 1.00 g of the mixture is uniformly mixed, the prepolymerization reaction is carried out at 50-110°C for 2 hours to obtain a polyurethane prepolymer.

[0053] (2) Add 50.7g of ammonia water (26wt%) to the polyurethane prepolymer at room temperature, then add 850.0g of water to disperse, and then add 71.0g of chain extender ethylenediamine at 30°C to carry out the chain extension reaction for 3 hours. At room temperature, water-based polyurethane is obtained.

[0054] The performance data of the prepared water-based polyurethane is shown in Table 4:

[0055] Table 4 Performance data of waterborne polyurethane

[0056]

[0057]

[0058] It can be seen from Table 4 that when different hydrophilic monomers are used, ...

Embodiment 8

[0060] In this example, alkyd resin-modified polyisocyanate is used. The modification method is: mix 30 g of cottonseed oil and 4 g of glycerin evenly, heat up to 120 ° C, add 0.1 g of KOH catalyst, react at 200 ° C for 2 hours, and cool down Finally, add 3g of benzoic acid and react at 180°C for 2h. When the temperature is lowered to 40°C, add 30g of toluene diisocyanate and 20g of xylene, raise the temperature to 65°C and keep it for 2h. After cooling down to room temperature, filter to obtain the modified alkyd resin non-toxic polyisocyanate. It is used in the preparation of waterborne polyurethane.

[0061] (1) 480.0g of acetone, 522.0g of toluene diisocyanate modified by alkyd resin, 88.8g of aminopropyl cage silsesquioxane T88.8g, 100062.0g of polyethylene glycol, 104.0g of hydrophilic monomer, catalyst After mixing 1.00 g of di-n-butyltin dilaurate evenly, conduct a prepolymerization reaction at 50-110° C. for 2 hours to obtain a polyurethane prepolymer.

[0062] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com