Double-surface die inner injection moulding product and production method thereof

A product manufacturing and internal injection molding technology, which is applied to double-sided in-mold injection molding products and its manufacturing field, can solve problems such as product deformation, uncomfortable eyes, and inability to meet spatial dynamic three-dimensional patterns, etc., to achieve yield improvement and low production difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

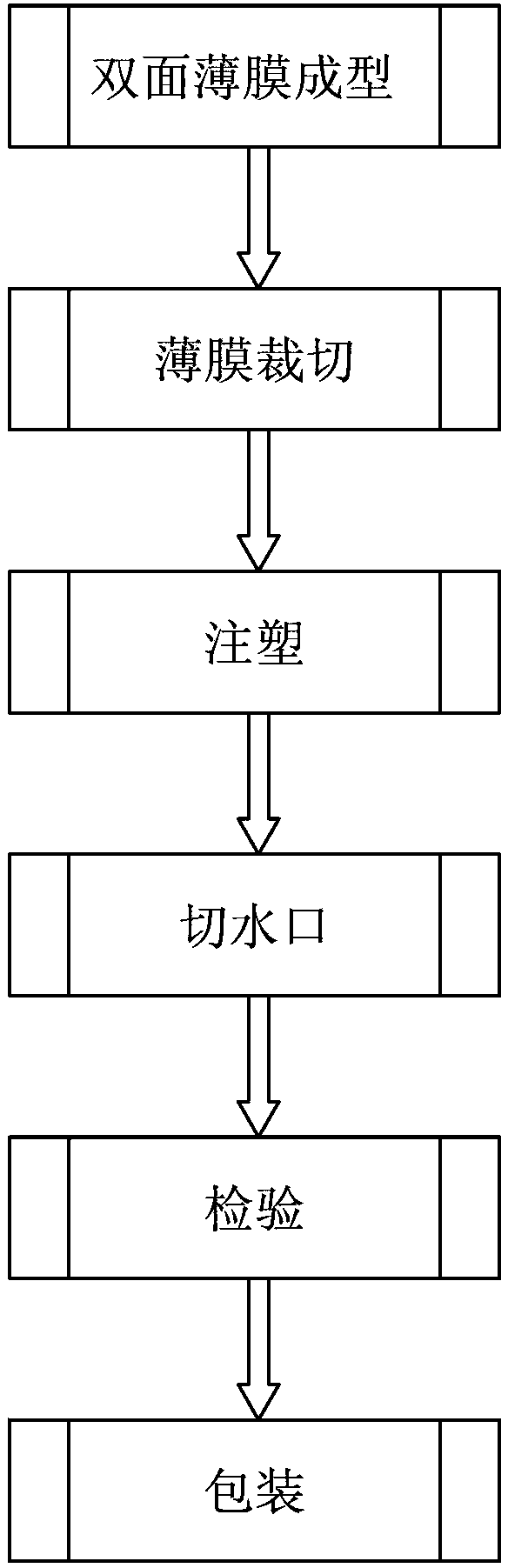

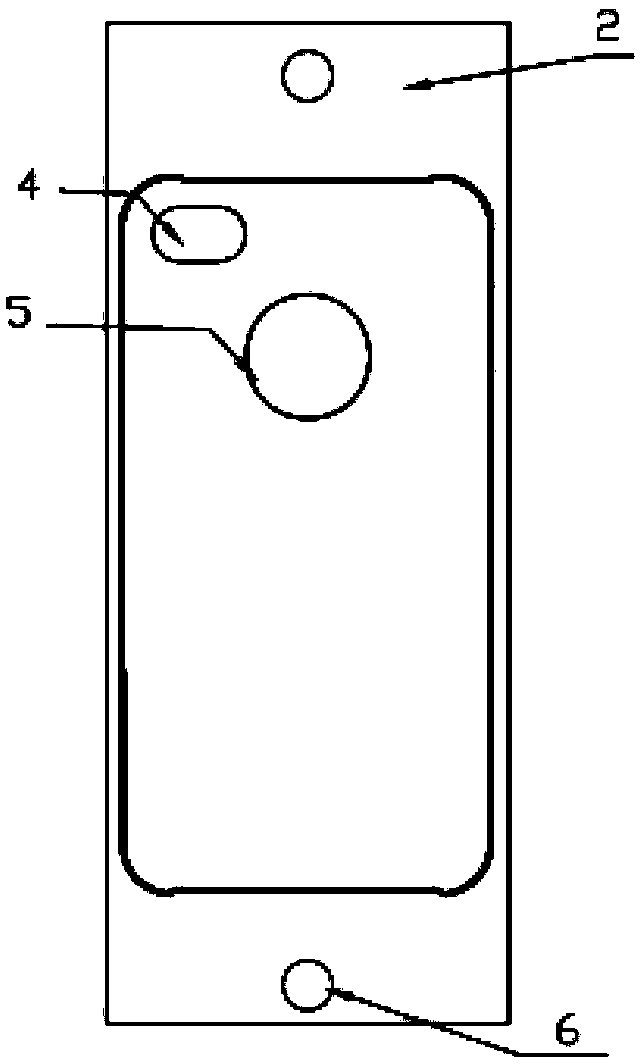

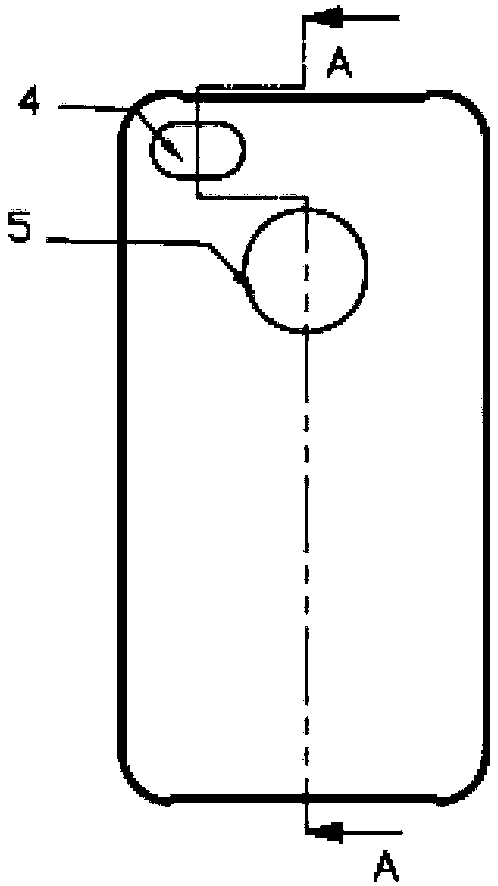

[0049] In step S12, the front film 2 and the back film 3 are respectively formed by a pneumatic forming machine, and the position marked with the first positioning hole 6 on the film is fixed corresponding to the positioning column of the forming mold. The film is heated for 3s and formed into the desired shape, the forming time is 2s

[0050] In the S2 film cutting step, the formed film produced in the previous step is cut, and the cutting time is set to 0.3s;

[0051] In the S3 injection molding step, the amount of melt injection used is increased by 8%, and the holding time is extended by 3s, and the cooling time is 15s to ensure that the melt can continue to be replenished after the product cools and shrinks.

[0052] During injection molding, the temperature of the mold at the position of the back film is set to 65°C; the temperature of the mold at the position of the front film is set at 50°C and controlled by a water temperature machine;

[0053] The other steps are th...

Embodiment 2

[0055] In step S12, the front film 2 and the back film 3 are respectively formed by a pneumatic forming machine, and the position marked with the first positioning hole 6 on the film is fixed corresponding to the positioning column of the forming mold, and then the film is started at a temperature of 500°C. The film is heated for 5s and formed into the desired shape, the forming time is 3s, and the formed film is taken out;

[0056] In the S2 film cutting step, the formed film produced in the previous step is cut, and the cutting time is 0.5s;

[0057] In the S3 injection molding step, the amount of molten material used in the injection molding process is increased by 10%, and the holding time is extended by 5s, and the cooling time is 18s to ensure that the melt can continue to be replenished after the product cools and shrinks;

[0058] During injection molding, the temperature of the mold at the position of the back film is set to 80°C; the temperature of the mold at the po...

Embodiment 3

[0061] In step S12, use a pneumatic molding machine to form the front film and the back film respectively, fix the position marked with the first positioning hole 6 on the film corresponding to the positioning column of the forming mold, and then start to heat the film at a temperature of 550°C 7s, and molded into the desired shape, the molding time is 5s, and the formed film is taken out;

[0062] In the S2 film cutting step, the formed film produced in the previous step is cut, and the cutting time is 0.7s;

[0063] In the S3 injection molding step, the amount of molten material used in the injection molding process is increased by 12%, and the holding time is extended by 7s, and the cooling time is 20s to ensure that the melt can continue to be replenished after the product cools and shrinks.

[0064] During injection molding, the temperature of the mold at the position of the back film is set to 85°C; the temperature of the mold at the position of the front film is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com