Submerged arc furnace flue vacuum insulation pipe with compound fireproof pouring material layer

A technology for refractory castables and castables, which is applied in the direction of protecting pipes, heat preservation, and pipes through thermal insulation, and can solve the problems of lack of strength of thermal insulation materials, flattening of pipes, and reduction of power generation efficiency with waste heat from flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

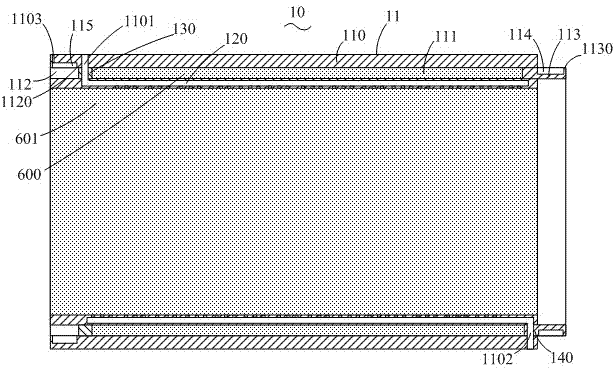

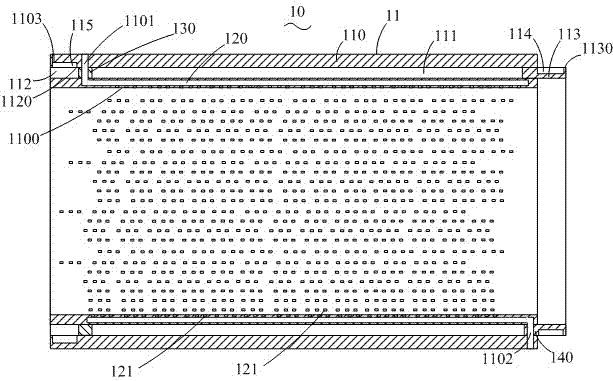

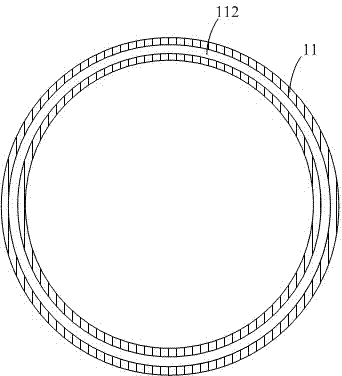

[0011] Please see Figure 1 to Figure 4 As shown, the submerged arc furnace flue gas vacuum insulation pipe 10 with a composite refractory castable layer includes a steel pipe body 11, a vacuum chamber 111 and a castable housing chamber 120 are arranged in the pipe wall 110 of the steel pipe body 11, and the vacuum chamber 111 1. The shape of the castable storage cavity 120 corresponds to the shape of the steel pipe main body 11, the vacuum cavity 111 and the castable storage cavity 120 are coaxial, and the distance from the castable storage cavity 120 to the inner pipe wall 1100 of the steel pipe main body 11 Less than the distance from the vacuum cavity 111 to the inner pipe wall 1100 of the steel pipe body 11, the pipe wall 110 of the steel pipe body 11 is provided with a first refractory castable injection hole 1101 and a second refractory castable injection hole 1102, the first refractory castable The injection hole 1101 and the second refractory castable injection hole 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com