Method and device for direct drying and redrying of tobacco strips

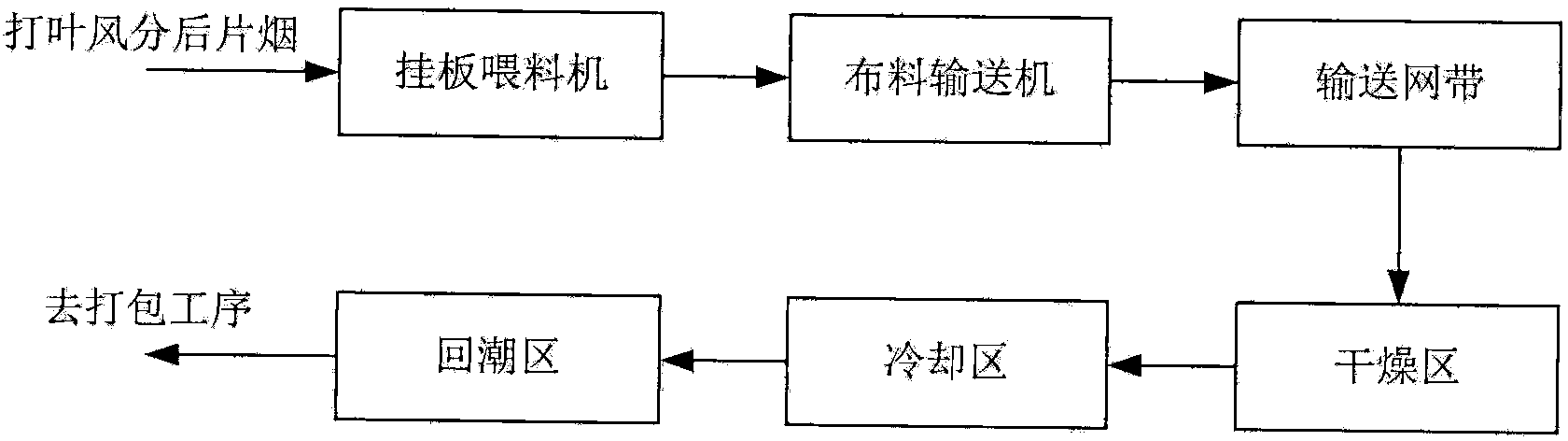

A cigarette and drying technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficulty in adapting to the processing requirements of large-flow materials, high energy consumption of air drying method, complicated equipment and devices, etc., and simplify the re-baking process of cigarettes. , The effect of improving the quality of raw material taste absorption and drying energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

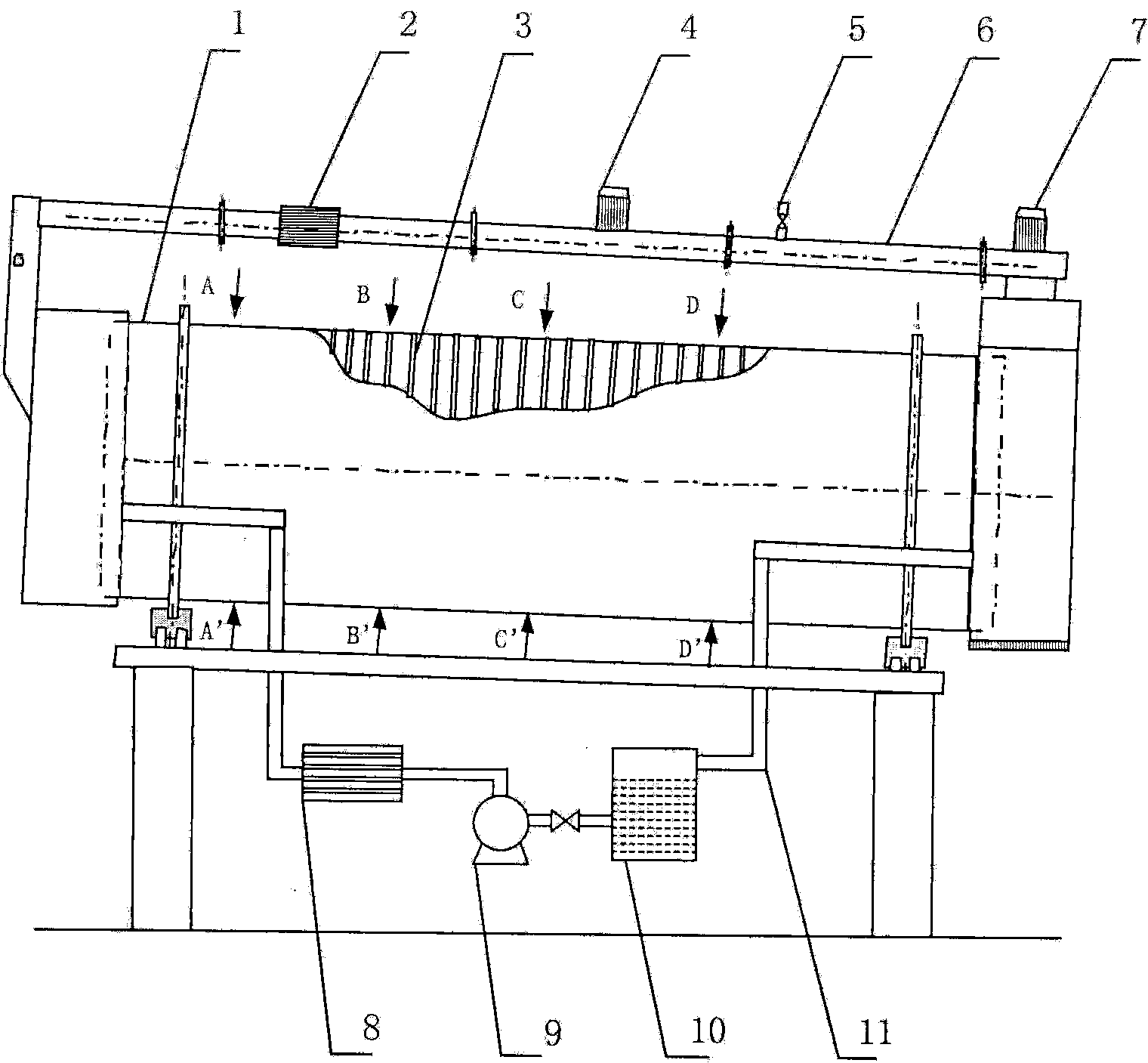

[0030] The present invention is further described below in conjunction with accompanying drawing:

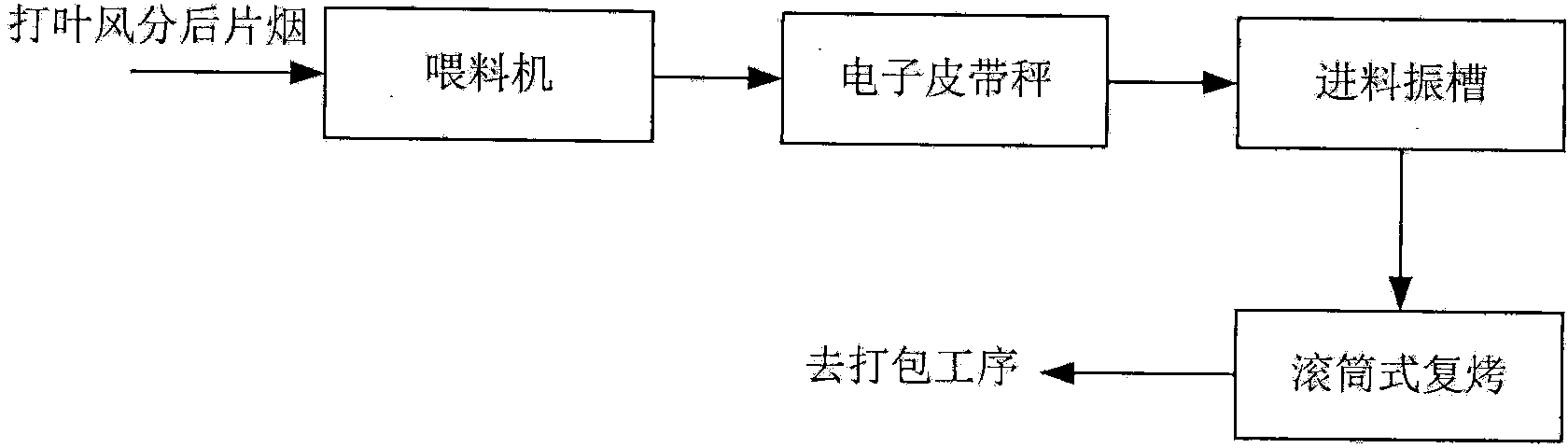

[0031] Such as figure 2 As shown: the direct drying and redrying method of sheet tobacco of the present invention includes the following process steps: the sheet tobacco is sent to the feeding vibrating tank at a stable flow rate through the feeder and the electronic belt scale, and the sheet tobacco is input into the drum from the feeding vibrating tank Type tobacco re-baking device, sequentially pass through the drying area of the lifting plate with variable inclination angle and plate width in the front section of the drum and the drying area of raking nails in the rear section of the drum. It is in full contact with the heated cylinder wall, and is dried by conduction-convection compound heat transfer. In the rear section, the rake nails the drying area, and the leaves continue to be in contact with the hot air with high humidity and the cylinder wall during the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com