Preparation method of high-performance motor vehicle antifreeze fluid

An automobile antifreeze, high-performance technology, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of antifreeze performance, thermal stability and corrosion resistance stability of antifreeze that cannot meet the requirements, and achieve thermal stability Excellent, high boiling point, strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

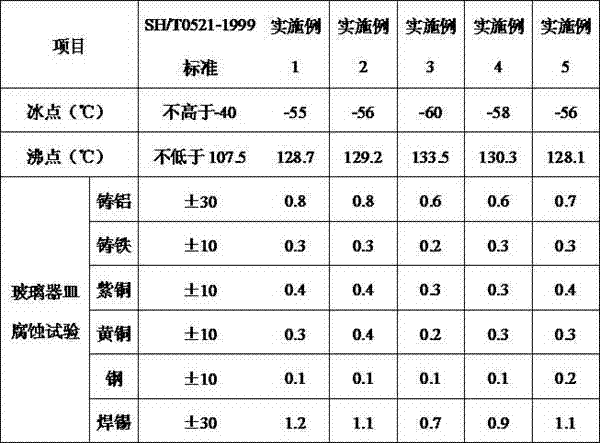

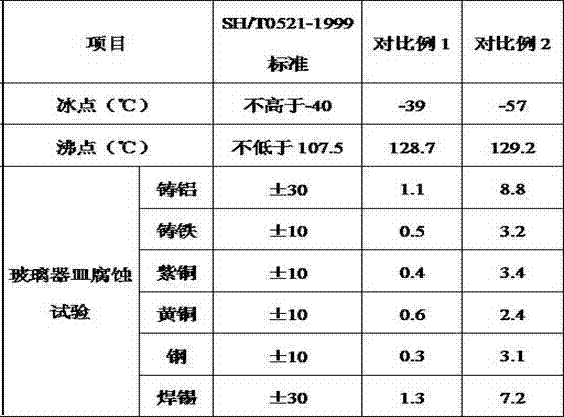

Examples

Embodiment 1

[0018] An automobile antifreeze liquid, comprising 70 parts by weight of components: 70 parts of ethylene glycol, 2 parts of adipic acid, 2 parts of sodium benzoate, 1 part of sodium salicylate, 4 parts of acrylic acid, 1 part of sodium bisulfite, 3 parts of octanoic acid 5 parts, 5 parts of isopropanol, 2 parts of sebacic acid, 5 parts of glycerin, 0.5 parts of sodium pentachlorophenate, 0.2 parts of polysiloxane, 1 part of sodium hexametaphosphate, and 50 parts of deionized water.

[0019] The preparation method step of above automobile antifreeze is as follows:

[0020] (1) take each component according to parts by weight;

[0021] (2) Mix and dissolve ethylene glycol, deionized water and glycerin, raise the temperature to 40°C, add other components, fully stir, mix and dissolve;

[0022] (3) The temperature of the mixed solution obtained in step (2) is raised to 60° C., and the mixture is kept at a vacuum of 0.02 MPa for 30 minutes to obtain an automobile antifreeze. ...

Embodiment 2

[0024] An automobile antifreeze liquid, comprising: 73 parts of ethylene glycol, 3 parts of adipic acid, 3 parts of sodium benzoate, 2 parts of sodium salicylate, 5 parts of acrylic acid, 2 parts of sodium bisulfite, 4 parts of caprylic acid by weight components 6 parts of isopropanol, 3 parts of sebacic acid, 7 parts of glycerin, 1 part of sodium pentachlorophenate, 0.5 parts of emulsified silicone oil, 2 parts of sodium hexametaphosphate, and 55 parts of deionized water.

[0025] The preparation method step of above automobile antifreeze is as follows:

[0026] (1) take each component according to parts by weight;

[0027] (2) Mix and dissolve ethylene glycol, deionized water and glycerin, raise the temperature to 42°C, add other components, fully stir and mix and dissolve;

[0028] (3) The temperature of the mixture obtained in step (2) is raised to 63° C., and the mixture is kept at a vacuum of 0.02 MPa for 35 minutes to obtain an automobile antifreeze.

Embodiment 3

[0030] A kind of automobile antifreeze liquid, comprising by weight components: 75 parts of ethylene glycol, 4 parts of adipic acid, 4 parts of sodium benzoate, 3 parts of sodium salicylate, 6 parts of acrylic acid, 4 parts of sodium bisulfite, 5 parts of octanoic acid 7 parts of isopropanol, 4 parts of sebacic acid, 8 parts of glycerin, 1.1 parts of sodium pentachlorophenate, 0.6 parts of polysiloxane, 3 parts of sodium hexametaphosphate, and 56 parts of deionized water.

[0031] The preparation method step of above automobile antifreeze is as follows:

[0032] (1) take each component according to parts by weight;

[0033] (2) Mix and dissolve ethylene glycol, deionized water and glycerin, raise the temperature to 45°C, add other components, fully stir and mix and dissolve;

[0034] (3) The temperature of the mixed solution obtained in step (2) is raised to 63° C., and the mixture is kept at a vacuum of 0.03 MPa for 40 minutes to obtain the automobile antifreeze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com