Finishing method of titanium alloy seamless pipe

A technology for seamless tubes and titanium alloys, applied in the finishing field of titanium alloy seamless tubes, can solve the problems of affecting product performance, large loss of titanium metal, and high loss of titanium metal, so as to reduce titanium metal consumption, reduce oxidation, and simplify The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

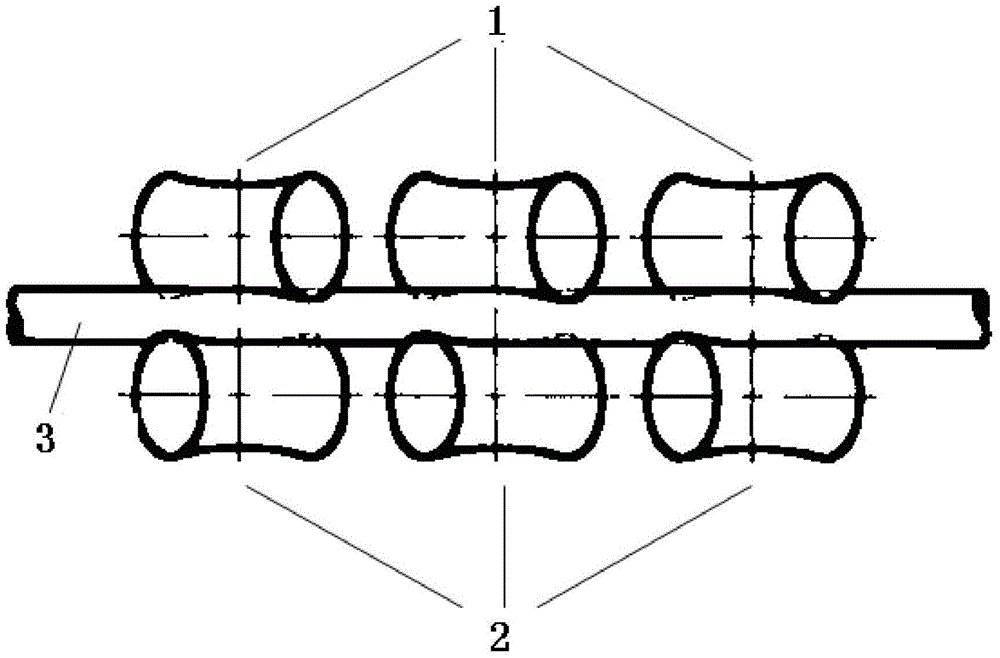

Image

Examples

Embodiment 1

[0026] Production of 73*5.51 titanium alloy tubes, process flow: titanium alloy seamless tubes are filled with aluminum silicate fibers → annealing heat treatment → primary temperature correction → cooling → secondary cold correction → pickling → rinse with water → check the inner and outer surfaces of titanium alloy tubes ,size and weight.

[0027] Among them, the annealing heat treatment temperature is 720 ° C, the residual oxygen in the heat treatment furnace is less than 3%, the temperature of the first temperature correction is 510 ± 10 ° C, the pickling solution used for pickling is 2.1% hydrofluoric acid, 12% nitric acid, and the rest is water. , Soak the titanium alloy tube in the pickling solution for 5 minutes. The bending degree of the titanium alloy tube obtained after finishing is less than 2mm / m, and the inner and outer surfaces of the titanium alloy tube are clean without defects such as cracks, folds, peeling, pinholes, etc., which meets the requirements of the...

Embodiment 3

[0031] Production of 114.3*6.88 titanium alloy tubes, process flow: titanium alloy seamless tubes are filled with aluminum silicate fibers → annealing heat treatment → primary temperature correction → cooling → secondary cold correction → pickling → rinse with water → check the inner and outer surfaces of titanium alloy tubes ,size and weight.

[0032] Among them, the annealing heat treatment temperature is 785°C, the residual oxygen in the heat treatment furnace is less than 3%, the primary temperature correction temperature is 580±10°C, the pickling solution used for pickling is 4.9% hydrofluoric acid, 26% nitric acid, and the rest is water. , Soak the titanium alloy tube in the pickling solution for 3 minutes. The bending degree of the titanium alloy tube obtained after finishing is less than 2mm / m, and the inner and outer surfaces of the titanium alloy tube are clean without defects such as cracks, folds, peeling, pinholes, etc., which meets the requirements of the finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com