Biogas slurry filtration column and use thereof

A filter column and biogas slurry technology, applied in the field of environmental engineering, can solve problems such as high suspended solids and blockage, achieve the effects of saving water resources, prolonging effective operating time, and ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

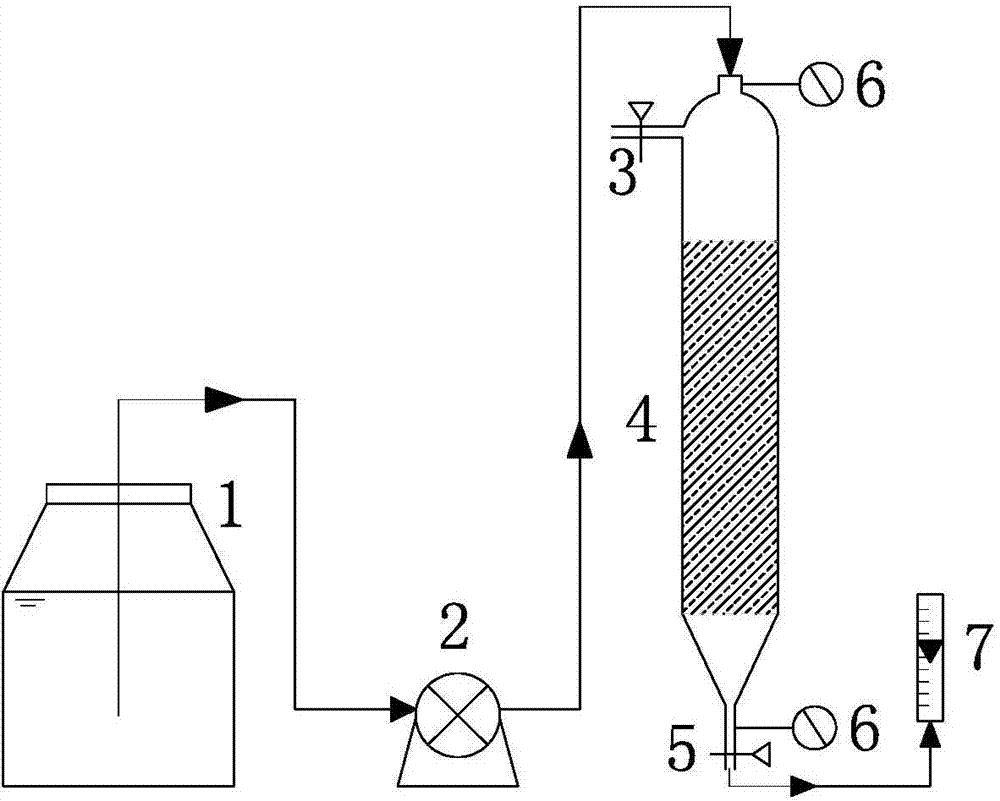

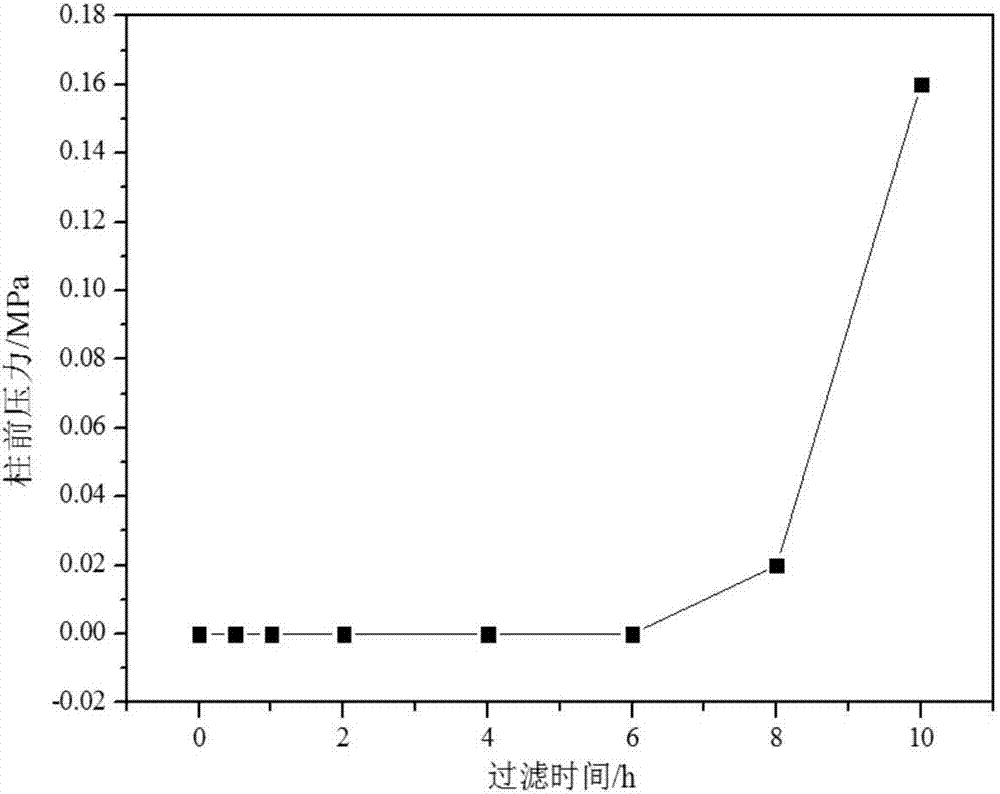

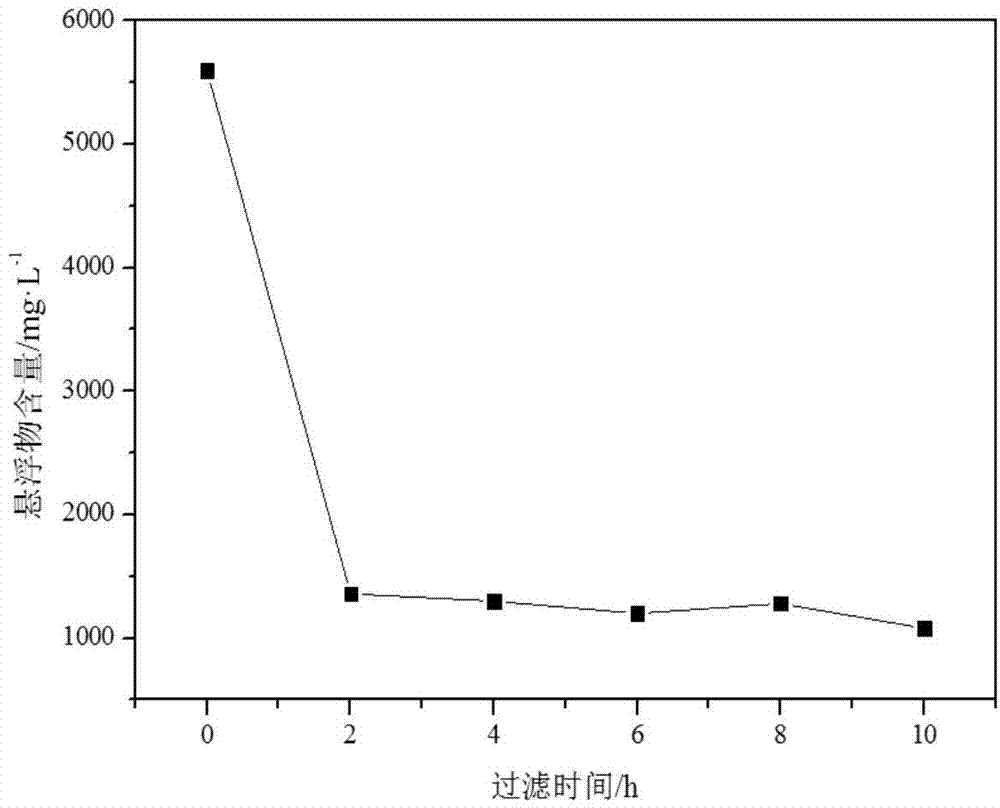

[0032] Example 1. Biogas slurry filter column filled with single-size corn stalks and its application

[0033] 1. Preparation of biogas slurry filter column filled with single particle size corn stalks

[0034] Pretreatment of corn stalks:

[0035] Take naturally air-dried corn stalks with a mass moisture content of 9%, and pulverize them into small pieces of 45-50 mm with a small grinder with a pitch of 50 mm between toothed rollers, and sieve out granular corn stalks with a particle size of less than 50 mm.

[0036] Preparation of biogas slurry filter column:

[0037] The prepared granular corn stalks were loaded into a stainless steel filter column with an inner diameter of 10 cm and a height of 100 cm. Fill the corn stalks directly into the filter column, the filling height is 85cm, at this time, the bulk density of the corn stalks in the filter column is 0.1628g·cm -3 .

[0038] The biogas slurry filter column prepared above is connected to figure 1 In the schematic ...

Embodiment 2

[0047] Example 2, the filter column packed with multi-stage particle size corn stalks and its application

[0048] 1. Preparation of biogas slurry filter column filled with multi-stage particle size corn stalks

[0049] Pretreatment of corn stalks:

[0050] Take naturally air-dried corn stalks, the mass moisture content of which is 9%. First, use a small pulverizer with a toothed roller spacing of 50 mm to pulverize it into small sections of 45 to 50 mm, and then sieve it with a sieve with an aperture of 50 mm. The straw filter material with a coarse particle size (50mm) is used for standby, and the undersieve is crushed to a smaller particle size of 15-20mm by a grinder with a toothed roller spacing of 20mm; The powdered corn stalks are sieved out, and the sieve is used as straw filter material with a fine particle size (20mm) for later use.

[0051] Preparation of biogas slurry filter column:

[0052] The prepared corn stalks with two particle sizes were loaded into a sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com