Chip test board and chip test system

A technology for testing chips and chips to be tested, which is applied in the direction of electronic circuit testing, measuring electronics, and measuring devices. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a chip testing system, comprising: a signal generating unit, a processing unit, a display unit, a chip testing board and a chip to be tested located on the chip testing board, wherein,

[0033] The signal generating unit generates an excitation signal for the chip to run;

[0034] The processing unit is used to monitor or analyze the operating state of the chip, and transmit the monitored state or the analysis result to the display unit;

[0035] The display unit is used to display the status or result of chip operation.

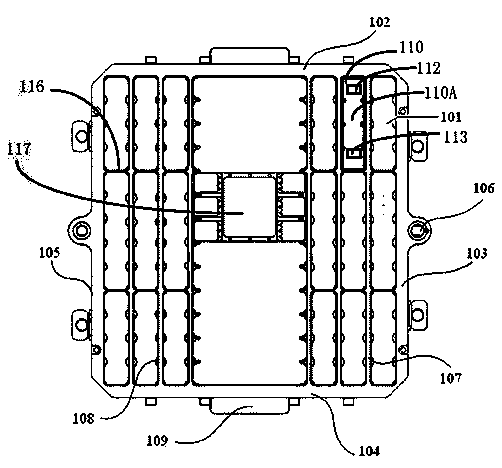

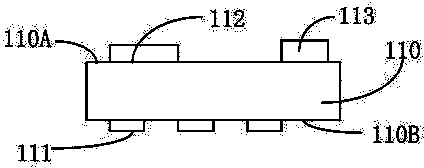

[0036] Specifically, such as figure 1 and image 3 As shown, the chip test board includes: a fixed frame 101 formed by vertically connecting successively the first crossbar, the second crossbar, the third crossbar, and the fourth crossbar (102, 103, 104, 105), and At least one PCB board 110 detachably connected to the fixing frame 101 allows the PCB board 110 to be selectively placed in the fixing frame 101 . According to th...

Embodiment 2

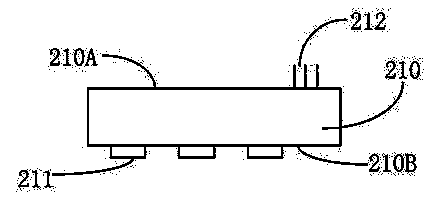

[0046] Such as figure 1 and Figure 4 As shown, the back side 210B of the PCB board 210 is provided with a pogo pin copper clad plate 211 electrically connected to the test machine, and the front side 210A of the PCB board 210 is provided with an electrical channel that can lead out the test machine to connect with the chip test board. The leading end 212 of the signal. The lead end 212 is connected to the chip under test. At the same time, the lead-out end can also be connected to the test base 113 on another PCB board 110 on the same fixed frame 101, and a plurality of PCB boards (110, 210) of different sizes can be formulated for combined use according to actual needs, reducing The size of a single PCB board is small, and PCB boards of different sizes can be reused to reduce costs.

[0047] Other parts are the same as those in Embodiment 1, and will not be repeated here.

[0048] To sum up, in the chip test board and the chip test system provided by the embodiments of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com