Assembling system of vehicle-mounted charging machine and modules for integrated functions of vehicle-mounted charging machine

A vehicle-mounted charger and assembly system technology, applied in the field of machinery, can solve the problems of many product quality interventions, low product quality, large production area, etc., and achieve the effect of reducing intervention, reducing inventory, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a vehicle-mounted charger and a module assembly system with integrated functions, such as Figure 1-Figure 3 As shown, the product processing steps are as follows:

[0033] S1. Product loading: manually load the product on the designated position of the turntable;

[0034] S2. Product marking: the product is sent to the marking mechanism through the turntable for marking, and the clamp completely squeezes the connector sealing ring, and locks the connector fixing screw during the pressing process;

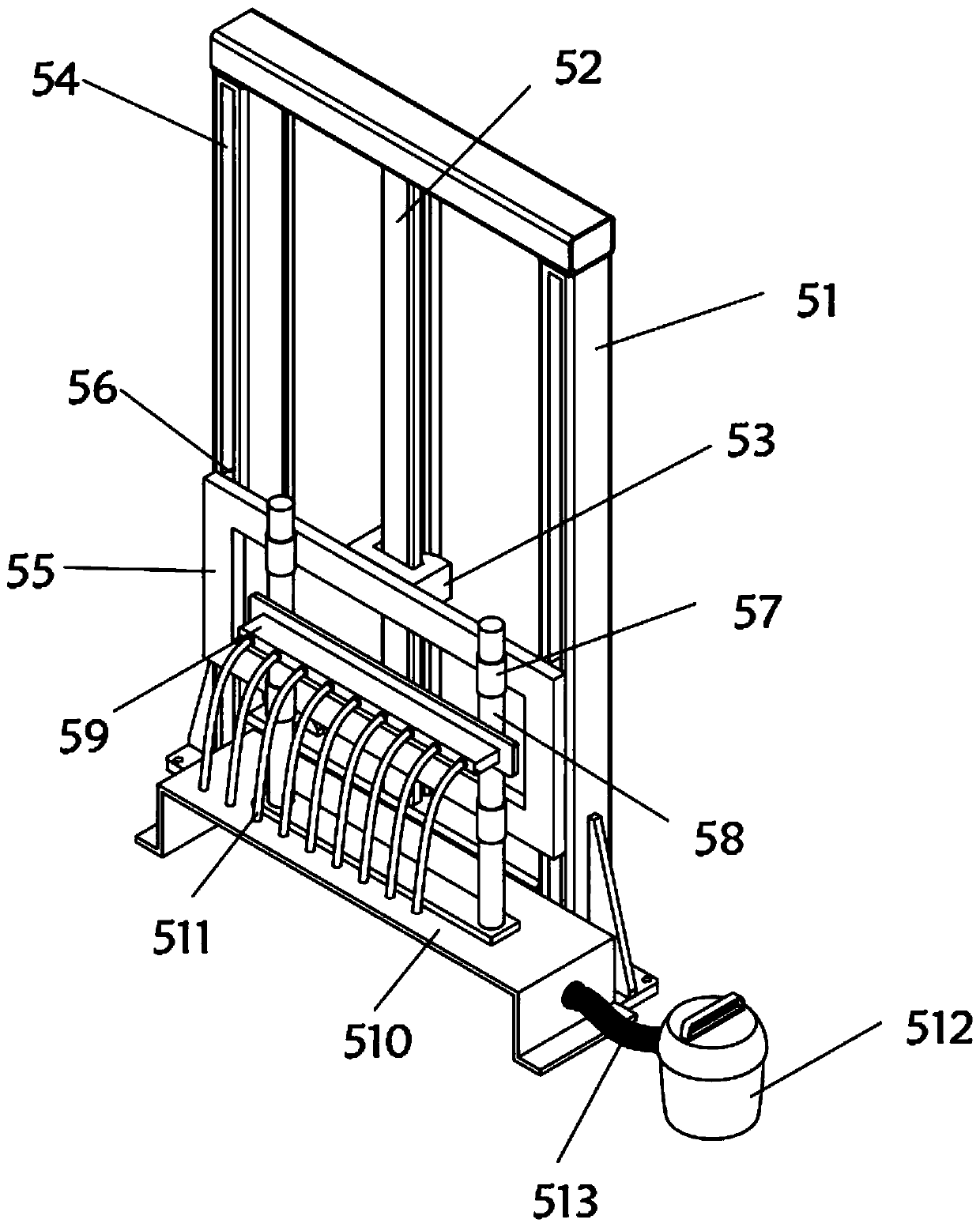

[0035] S3. Product screwing: After the label is finished, it is sent to the automatic screwing mechanism through the turntable for screwing;

[0036] S4. Product dust removal: after the screw is screwed, the product is sent to the dust removal mechanism by the turntable for cleaning, and the product is surrounded by an airtight cover. The ion wind blows the inside of the shell, and a vacuum cleaner is installed at the bottom to collect the blown parti...

Embodiment 2

[0045] As the second embodiment of the present invention, in order to facilitate dispensing work on workpieces, the present invention provides a module assembly system for an on-board charger and its integrated functions, such as Figure 4 As shown, the product dispensing operation steps are as follows:

[0046] S5. Product dispensing: After the product is cleaned, it is sent to the manual loading place by the turntable, and then the processed product is manually removed and sent to the dispensing mechanism, and the product shell is coated with heat-dissipating glue through the three-axis automatic dispensing mechanism;

[0047] S6. Glue removal of module products: Send the products coated with heat dissipation glue to the weighing glue removal module, scrape off the waste glue on the products, and weigh them.

[0048] In this embodiment, the dispensing mechanism in S5 includes an operation panel 61, and an automatic dispensing mechanism 62 and an electronic scale 63 are respe...

Embodiment 3

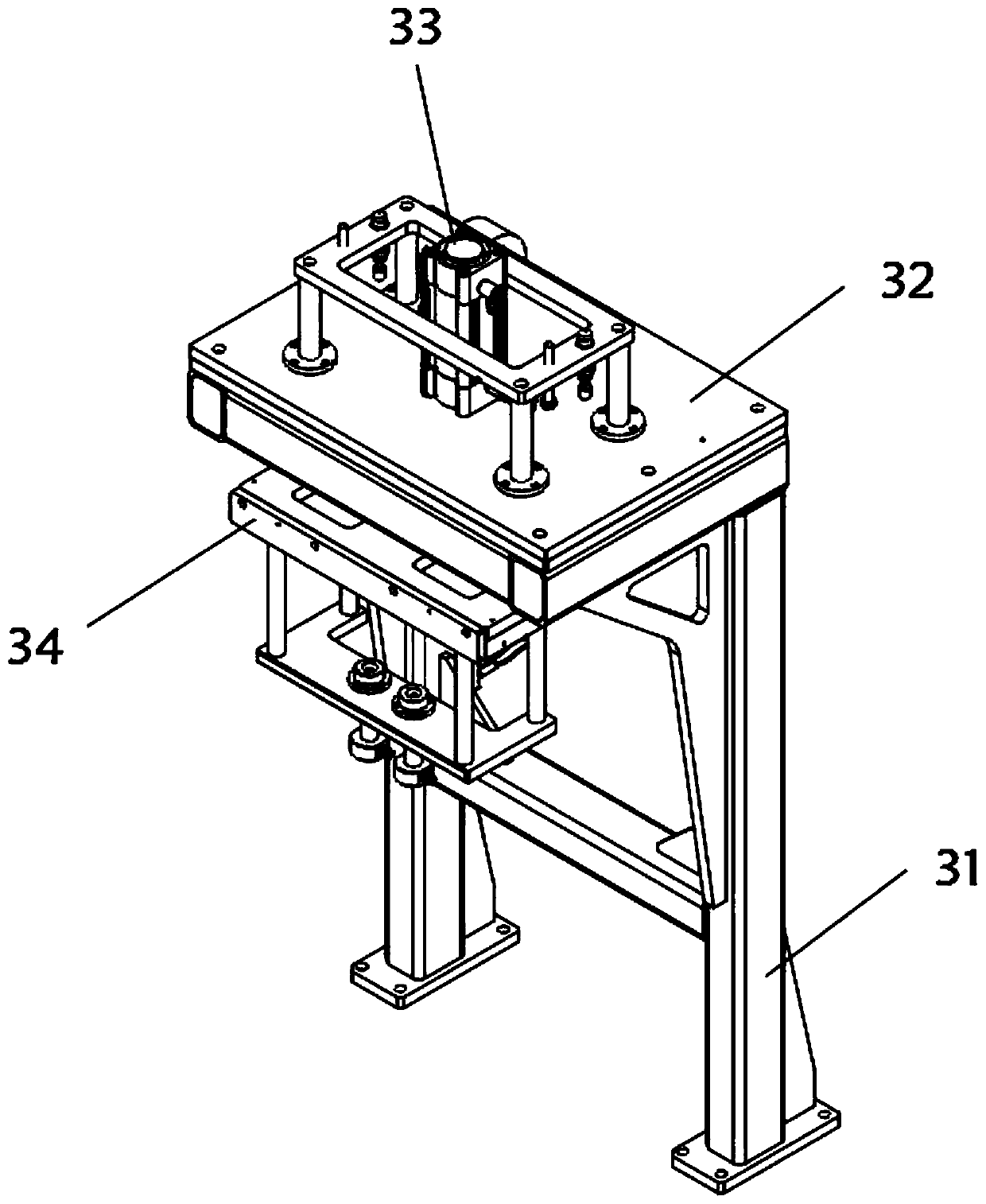

[0052] As a third embodiment of the present invention, in order to facilitate the screwing work on workpieces, the present invention provides a module assembly system for an on-board charger and its integrated functions, such as Figure 5 and Figure 6 As shown, the product screwing operation steps are as follows:

[0053] S7, PCBA screwing: transfer the product to the three-axis screwing station, and tighten the screws on the PCBA.

[0054] In this embodiment, the three-axis screwing station in S7 includes a desktop board 71, which is respectively provided with a three-axis screwing mechanism 72 and a transmission line 73, and a jacking cylinder 74 is installed on the bottom of the desktop board 71, and the desktop board 71 A jacking platform 75 is installed on the top.

[0055] Among them, the three-axis screwing mechanism 72 adopts the three-axis screwing machine model JL-L5331 produced by Shenzhen Juli Electromechanical Automation Co., Ltd. The supporting circuit and ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com