A device and method for three-dimensional coordinate calibration of tof depth cameras based on virtual multi-sphere center positioning

A technology of depth camera and calibration method, which is applied in measurement devices, testing of machine/structural components, instruments, etc., can solve problems affecting the accuracy and repeatability of TOF depth camera calibration results, high complexity of target recognition and feature extraction, and limitations. TOF depth camera application range and other issues, to achieve the effect of improving 3D coordinate calibration accuracy, reducing difficulty and error, and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

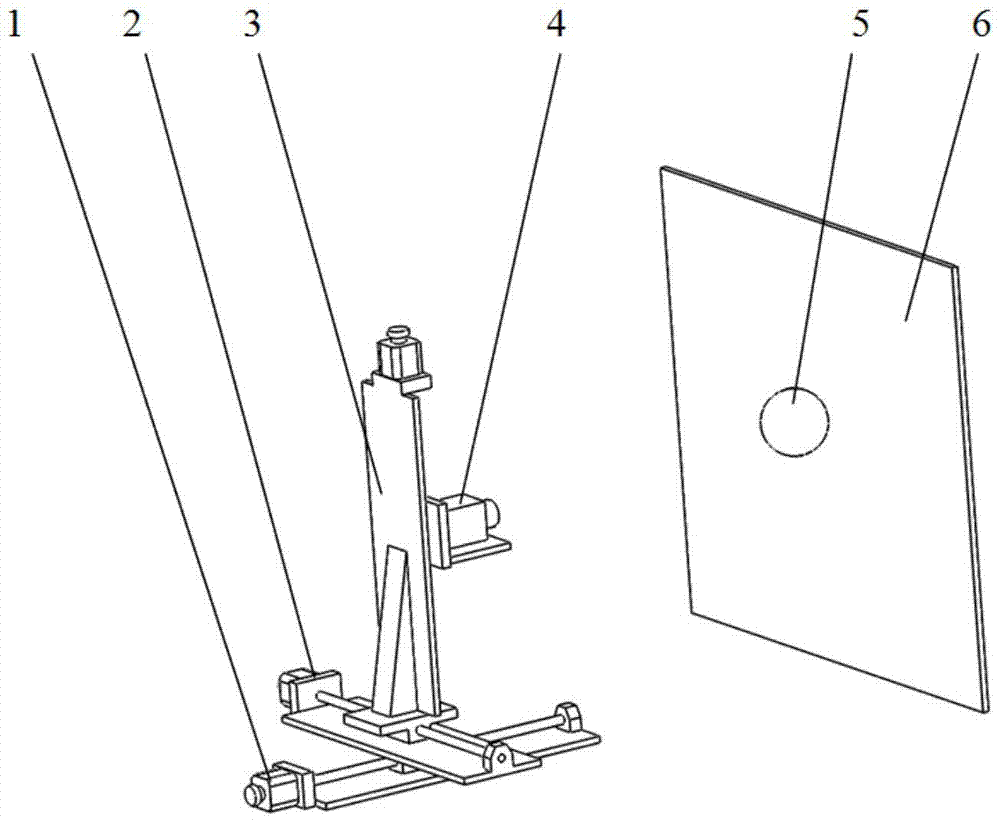

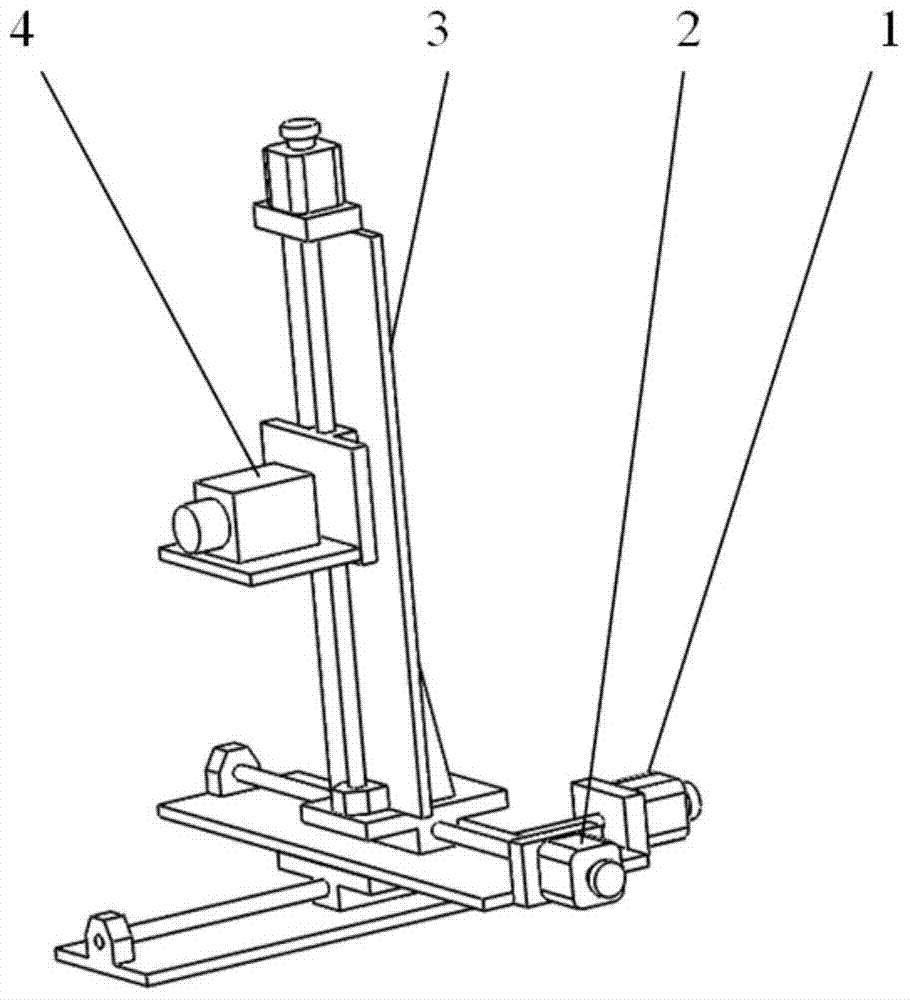

[0046] Taking the TOF depth camera 4 at a distance of 500 mm, the combination of the X-direction moving translation platform 2 and the Y-direction moving translation platform 3 to carry out 3×3 movement in the XY plane for three-dimensional coordinate calibration as an example, describe in detail the calibration device introduced in the present invention and Methods as below:

[0047] (1) First determine the space coordinate system OXYZ, the three translation axes of the three-dimensional translation platform are defined as the three directions of X, Y, and Z, the coordinate origin O is positioned as the lens center of the TOF depth camera 4, and the bottom surface of the three-dimensional motion translation platform is defined as The XZ plane is parallel to the installation bottom surface of the TOF depth camera 4; the Z direction is the optical axis direction of the TOF depth camera 4, and is parallel to the movement direction of the translation axis of the translation platfo...

Embodiment 2

[0059] Such as Image 6 As shown, the spherical target 5 is a target with more than 50% of the whole part having a spherical shape, and the other components and working principles of this embodiment are the same as those of the first embodiment.

[0060] In a word, the present invention reduces the difficulty and measurement error of a single TOF depth camera for the center point feature recognition of a spherical target, effectively improves the three-dimensional measurement accuracy of the TOF depth camera, and can flexibly set the center position and number of virtual standard spheres, making it easy to Realize the whole process of high-precision automatic calibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com