Microfluidic Microvalve and Driving Device

A driving device and microfluidic technology, applied in valve devices, components of pumping devices for elastic fluids, valve operation/release devices, etc., can solve reliability risks, easy leakage of micro-membrane pumps, chip failure, etc. problem, to achieve the effect of improving transmission efficiency, solving the failure of microvalve function, and convenient chip installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

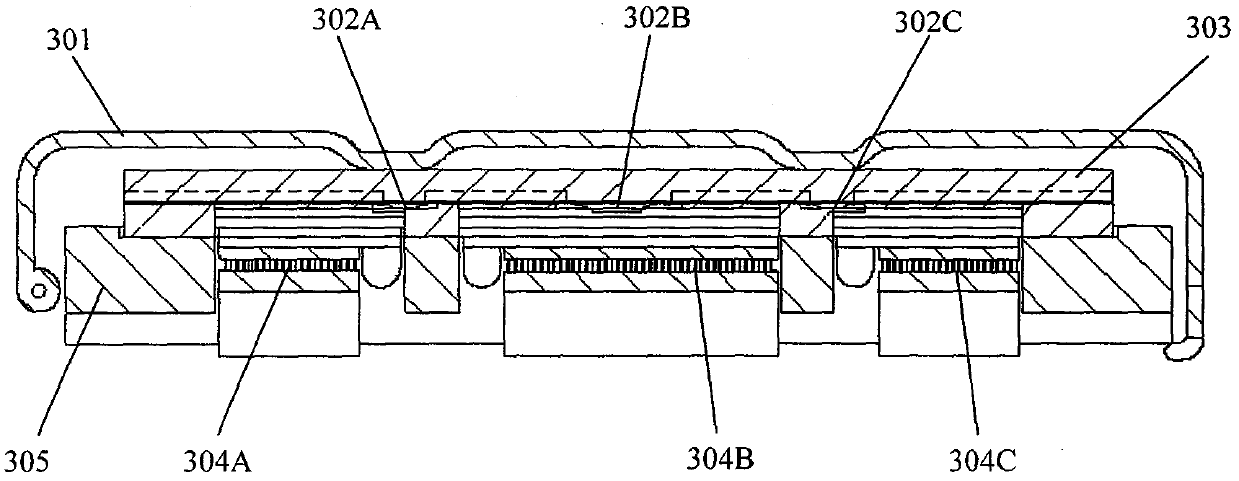

[0013] By adopting the solution embodiment of the present invention, the micro-membrane pump can be driven to realize bidirectional movement of fluid. Such as image 3 Three microfluidic microvalves 302A, 302B, and 302C provided by the present invention are connected in series on the chip 303 to form a two-way volume displacement pump. Among them, the microfluidic microvalve 302B in the middle is larger and constitutes a replacement cavity, and the microfluidic microvalves 302A and 302C are check valves. The chip 303 is fixed by the tray 305 and the clip 301, so that the heat exchange surfaces of the three microfluidic microvalves 302A, 302B, 302C on the chip 303 are in good contact with the heat control surfaces of the temperature control devices 304A, 304B, 304C on the tray 306. Each microvalve corresponds to a set of temperature control devices, and the closed-loop control of each microvalve on the chip 303 is realized through semiconductor refrigerators and temperature se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com