Solid oxide electrolysis cell cathode material as well as preparation method and application thereof

A solid oxide and cathode material technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of small powder particle size, low synthesis temperature, affecting the electrochemical performance of cathode materials in solid oxide electrolytic cells, etc., to achieve Improving the electrochemical performance and eliminating the effect of impurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

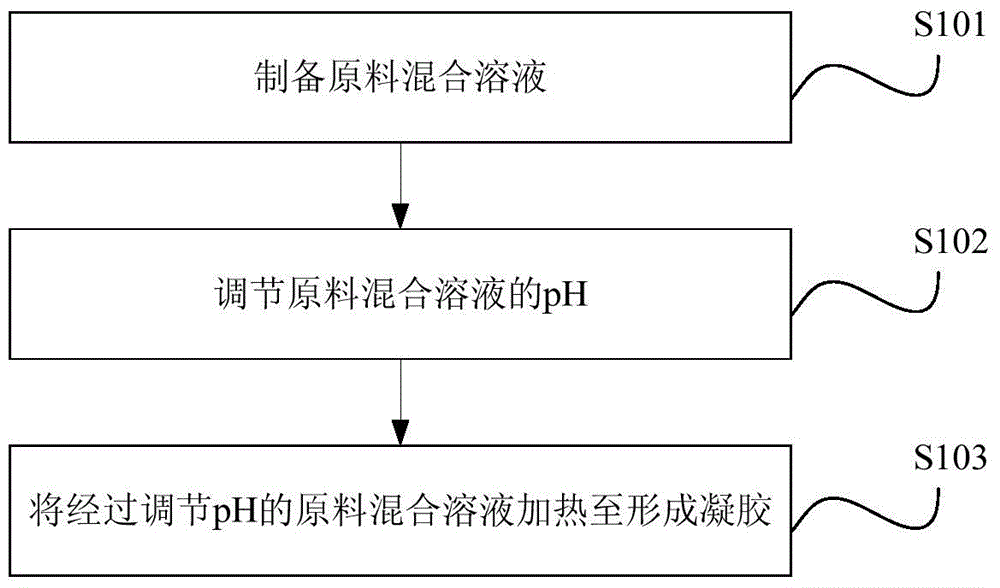

Method used

Image

Examples

Embodiment 1

[0051] Take Sr(NO 3 ) 2 , Fe(NO 3 ) 3 ·9H 2 O, Mg(NO 3 ) 2 ·6H 2 O, (NH 4 ) 6 Mo 7 O 24 ·4H 2 O is the raw material, press Sr 2 Fe 0.9 Mg 0.1 MoO 6-δ Weigh the required raw materials in a stoichiometric ratio, dissolve citric acid in an appropriate amount of deionized water, and add accurately weighed Sr(NO 3 ) 2 , Fe(NO 3 ) 3 ·9H 2 O, Mg(NO 3 ) 2 ·6H 2 O, in order to avoid the formation of iron molybdate precipitation under weak acid conditions, ammonium molybdate is dissolved in deionized water to form a clear solution and then added to the above mixed solution, wherein the molar ratio of citric acid to the total number of metal ions is 2:1. Then add ammonia water to adjust pH=3. Then the solution was heated and evaporated in a water bath at 90°C for several hours to form a gel. Next, put the gel in a 180°C thermostat to continue heating until it burns. After cooling, take out the fluffy combustion products and grind to obtain combustion powder. Place the combustion powder i...

Embodiment 2

[0055] Take Sr(NO 3 ) 2 , Fe(NO 3 ) 3 ·9H 2 O, (NH 4 ) 6 Mo 7 O 24 ·4H 2 O is the raw material, press Sr 2 FeMoO 6-δ Weigh the required raw materials in a stoichiometric ratio, dissolve citric acid in an appropriate amount of deionized water, add accurately weighed Sr(NO 3 ) 2 , Fe(NO 3 ) 3 ·9H 2 O, in order to avoid the formation of iron molybdate precipitation under weak acid conditions, ammonium molybdate is dissolved in deionized water to form a clear solution and then added to the above mixed solution, wherein the molar ratio of citric acid to the total number of metal ions is 2:1. Then add ammonia water to adjust pH=2. Then the solution was heated and evaporated in a water bath at 90°C for several hours to form a gel. Next, put the gel in a 180°C thermostat to continue heating until it burns. After cooling, take out the fluffy combustion products and grind to obtain combustion powder. Place the combustion powder in an air atmosphere at 600°C for 4 hours to pre-fire to re...

Embodiment 3

[0059] Take Sr(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, (NH 4 ) 6 Mo 7 O 24 ·4H 2 O is the raw material, press Sr 2 MgMoO 6-δ Weigh the required raw materials in a stoichiometric ratio, dissolve citric acid in an appropriate amount of deionized water, add accurately weighed Sr(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, in order to avoid the formation of iron molybdate precipitation under weak acid conditions, ammonium molybdate is dissolved in deionized water to form a clear solution and then added to the above mixed solution, wherein the molar ratio of citric acid to the total number of metal ions is 2:1. Then add ammonia water to adjust pH=3. Then the solution was heated and evaporated in a 60°C water bath for several hours to form a gel. Next, put the gel in a 160°C thermostat to continue heating until it burns. After cooling, take out the fluffy combustion products and grind to obtain combustion powder. Place the combustion powder in an air atmosphere at 800°C for 2 hours to pre-fire to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com