Preparation method of anti-corrosion wear-resistant iron-based amorphous coating for boiler tube bundle

A technology of iron-based amorphous and boiler tube bundles, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problems that cannot be applied to large-scale structural materials, and achieve good bonding, excellent corrosion resistance, The effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

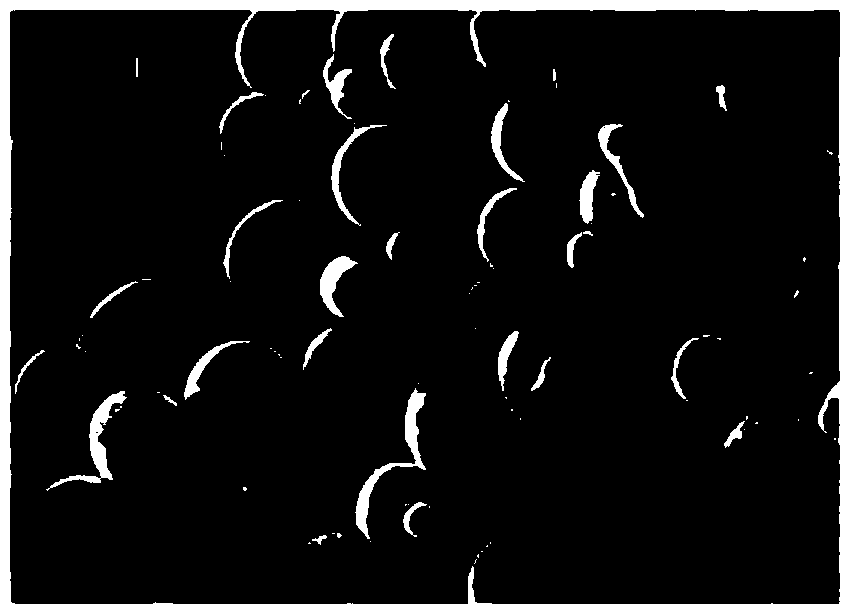

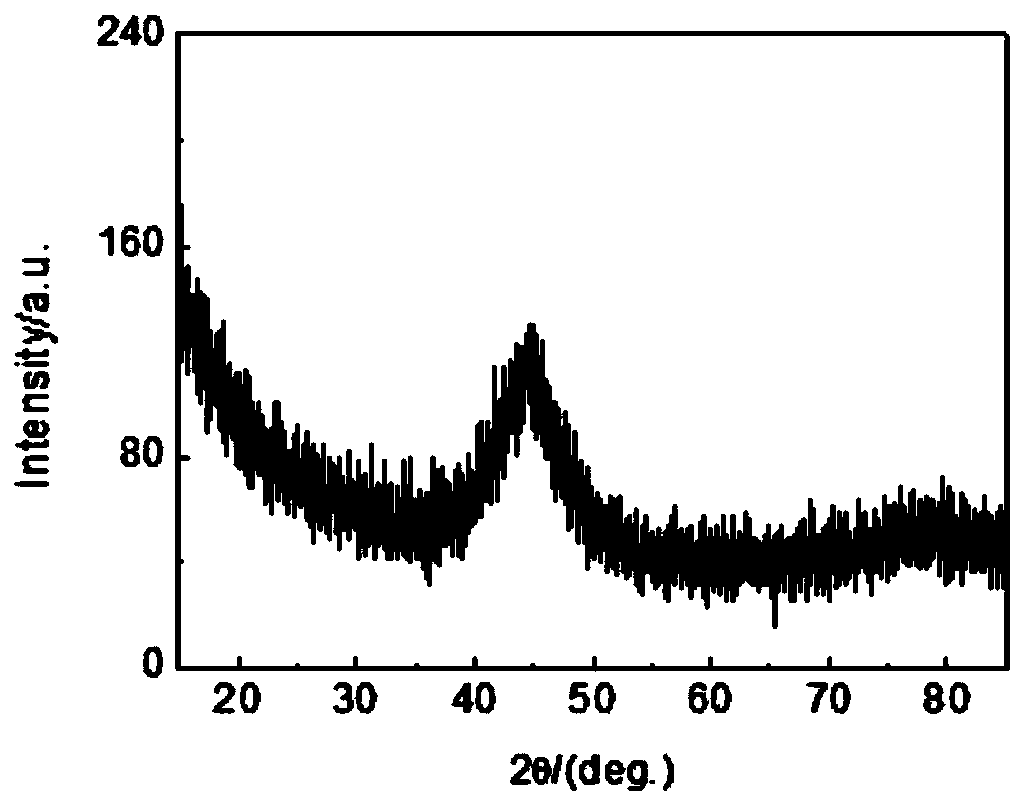

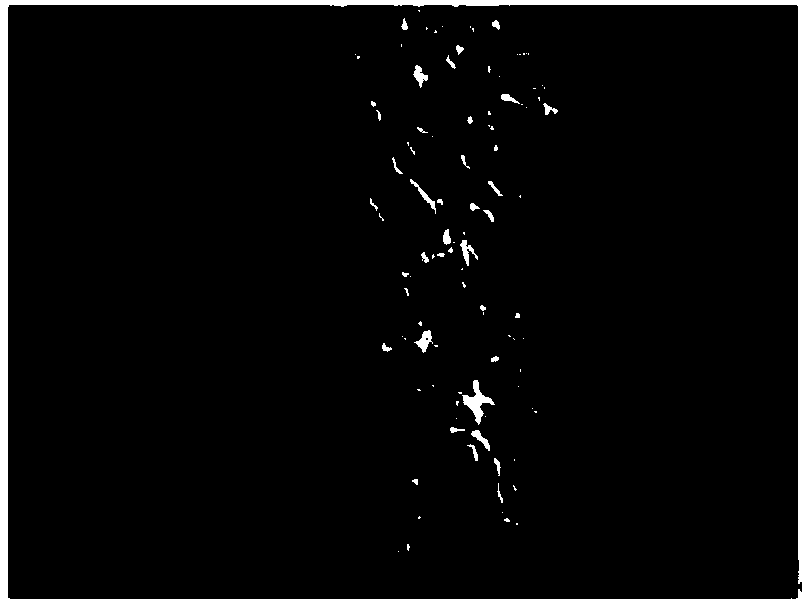

[0028] The method for preparing the corrosion-resistant and wear-resistant iron-based amorphous coating for the boiler tube bundle in this embodiment comprises the following steps:

[0029] Step 1, using the aerosol method to prepare iron-based amorphous alloy powder, the iron-based amorphous alloy powder is made by mixing the following raw materials in weight percentage: Mo0.5%, Cr11.0%, Ni12.5%, Si8. 0%, Al1.0%, C6.5%, the balance is Fe and unavoidable impurities; the particle size of the iron-based amorphous alloy powder is 50 μm;

[0030] Step 2. Prepare a corrosion-resistant and wear-resistant iron-based amorphous coating on the surface of the boiler tube bundle by using a plasma spraying process. The process parameters of the plasma spraying process are: arc voltage 65V, arc current 500A, argon gas flow rate 20L / min, the hydrogen flow rate is 7L / min, the spray gun moving speed is 50mm / s, and the spraying distance is 100mm; the thickness of the iron-based amorphous coatin...

Embodiment 2

[0037] The method for preparing the corrosion-resistant and wear-resistant iron-based amorphous coating for the boiler tube bundle in this embodiment comprises the following steps:

[0038] Step 1, using the aerosol method to prepare iron-based amorphous alloy powder, the iron-based amorphous alloy powder is made by mixing the following raw materials in weight percentage: Mo1.5%, Cr15.0%, Ni16.0%, Si6. 5%, Al3.0%, C8.5%, the balance is Fe and unavoidable impurities; the particle size of the iron-based amorphous alloy powder is 60 μm;

[0039] Step 2. Prepare a corrosion-resistant and wear-resistant iron-based amorphous coating on the surface of the boiler tube bundle by using a plasma spraying process. The process parameters of the plasma spraying process are: the arc voltage is 70V, the arc current is 550A, and the flow rate of argon gas The hydrogen flow rate is 25L / min, the hydrogen flow rate is 8L / min, the spray gun moving speed is 60mm / s, and the spraying distance is 110m...

Embodiment 3

[0042] The method for preparing the corrosion-resistant and wear-resistant iron-based amorphous coating for the boiler tube bundle in this embodiment comprises the following steps:

[0043] Step 1, using the aerosol method to prepare iron-based amorphous alloy powder, the iron-based amorphous alloy powder is made by mixing the following raw materials in weight percentage: Mo1.0%, Cr13.0%, Ni14.25%, Si7. 25%, Al2.0%, C7.5%, the balance is Fe and unavoidable impurities; the particle size of the iron-based amorphous alloy powder is 40 μm;

[0044] Step 2: Prepare a corrosion-resistant and wear-resistant iron-based amorphous coating on the surface of the boiler tube bundle by using a plasma spraying process. The flow rate is 15L / min, the hydrogen flow rate is 5L / min, the moving speed of the spray gun is 40mm / s, and the spraying distance is 90mm; the thickness of the iron-based amorphous coating is 200μm, and the material of the boiler tube bundle is 304H stainless steel.

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com