Dedusting structure of stokehold scrap iron runner of medium- and small-sized blast furnaces

A small and medium-sized, slag-iron ditch technology, used in dust collectors, discharge devices, etc., can solve the problems of environmental pollution, slag and iron are susceptible to cold adhesion, increase the difficulty of cleaning, etc., and achieve good insulation effect and reduce the effect of smoke and dust content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

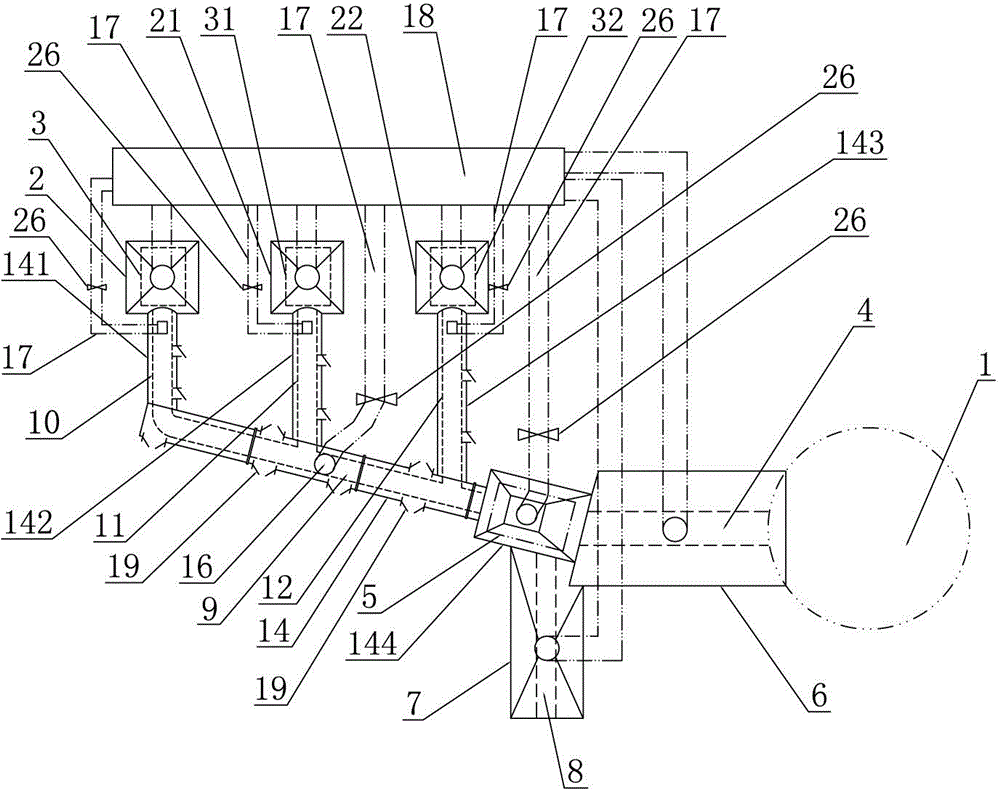

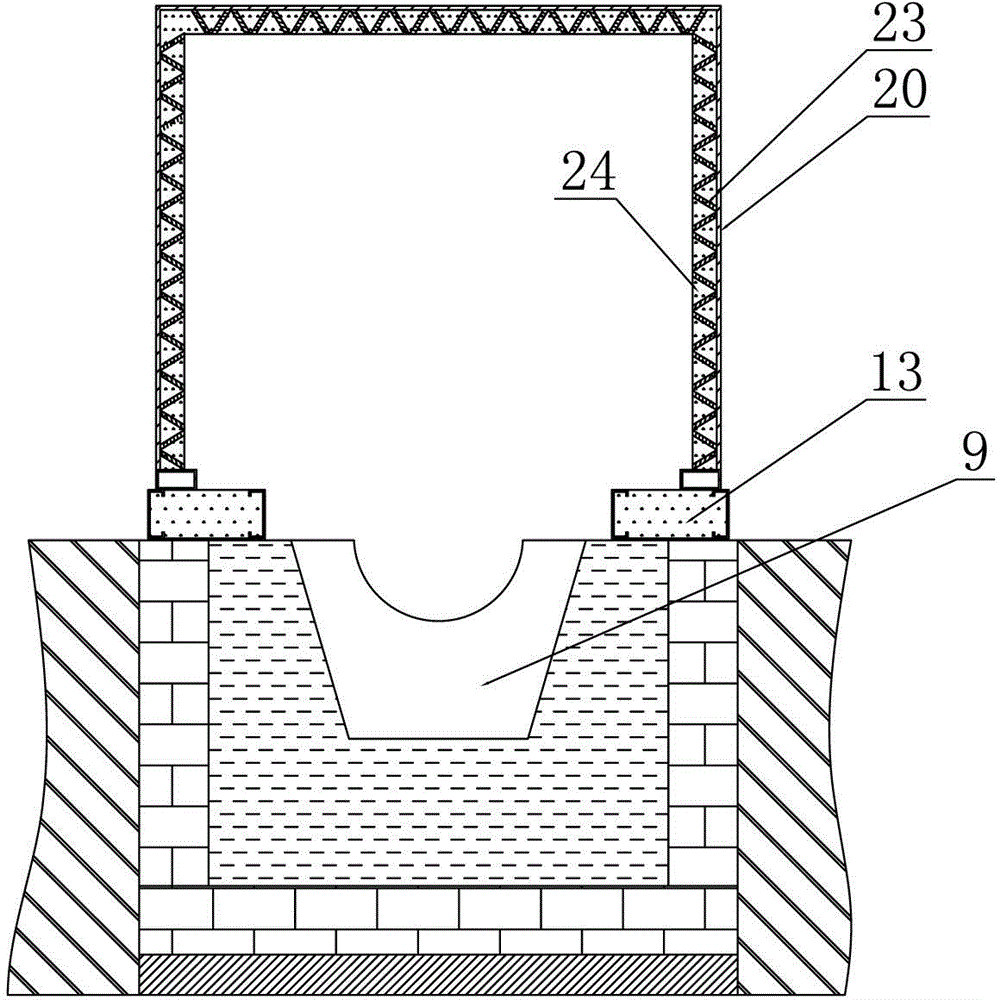

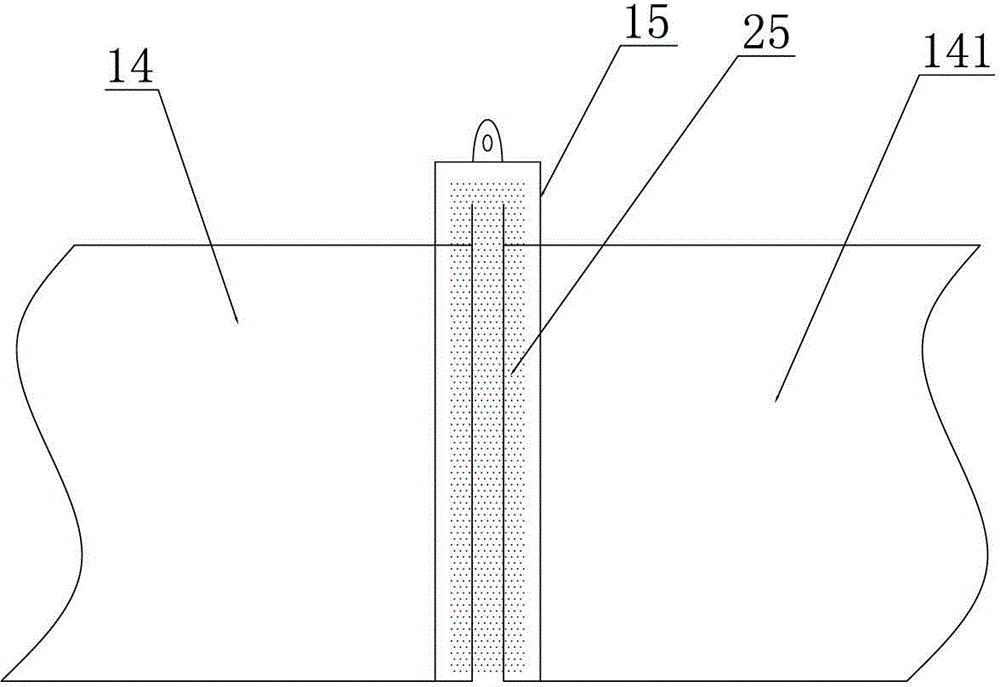

[0015] Such as figure 1 , figure 2 , image 3 As shown, the dust removal structure of the slag iron ditch in front of the small and medium-sized blast furnace includes: a blast furnace 1 and several covers are provided with the first molten iron tank position 3 of the first tank position top suction cover 2, and the second tank position top suction cover 2 1's tank position 31 of the second molten iron car, the third tank position top suction cover 22 and the third largest molten iron car tank position 32, the taphole of the blast furnace 1 is connected to the main ditch 4 covered with the top suction cover 6 of the tap hole , the main ditch 4 is connected to the inlet of the skimmer 5, the overflow port of the skimmer 5 is connected to the slag ditch 8 covered with the top suction cover 7 of the slag mouth, and the molten iron outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com