Up-draught biomass gasifier capable of heating fuel gas

A biomass and gasification furnace technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of the calorific value reduction of biomass hot gas, affecting the gasification furnace, liquid tar difficult to handle, etc., to achieve dust reduction and good filtration The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

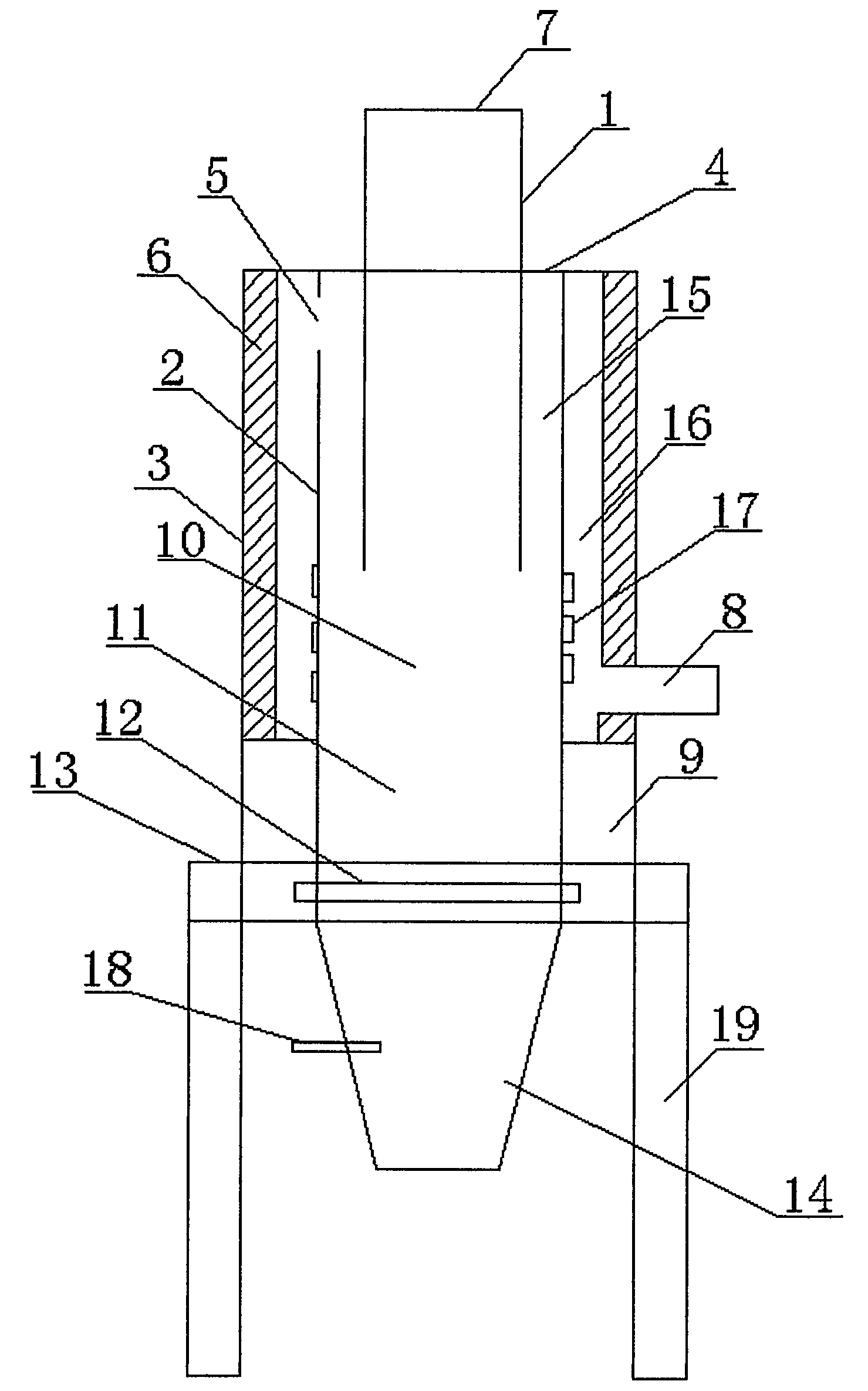

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0013] Such as figure 1 As shown, the gasifier includes an outer cylinder 3, a middle cylinder 2, an inner cylinder 1, the upper part of the inner cylinder 1 is a feed port 7, the upper part of the outer cylinder 3 has a cover plate 4, and the inner side of the outer cylinder 3 has a Insulation layer 6, water-cooled jacket 9 at the lower part of outer cylinder 3, gas outlet 8 at the middle and lower part of the outer cylinder, middle cylinder 2 connected to the inner side of water-cooled jacket 9, upper part of middle cylinder 2 connected with cover plate 4, middle cylinder The upper part of the body 2 has one or several air vents 5, the outer side of the middle cylinder 2 has heat transfer fins 17, the fire grate 12 is located at the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com