Magneto-calorific curing method for thermosetting resin adhesive

A curing method and adhesive technology, which is applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve the problems of heat-affected zone and low equipment investment, and achieve improved cross-linking density, short curing time, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

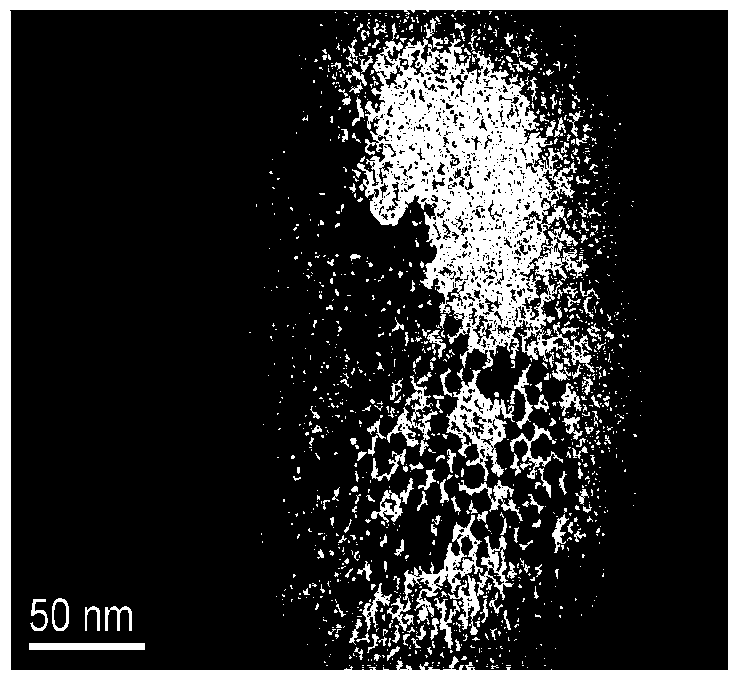

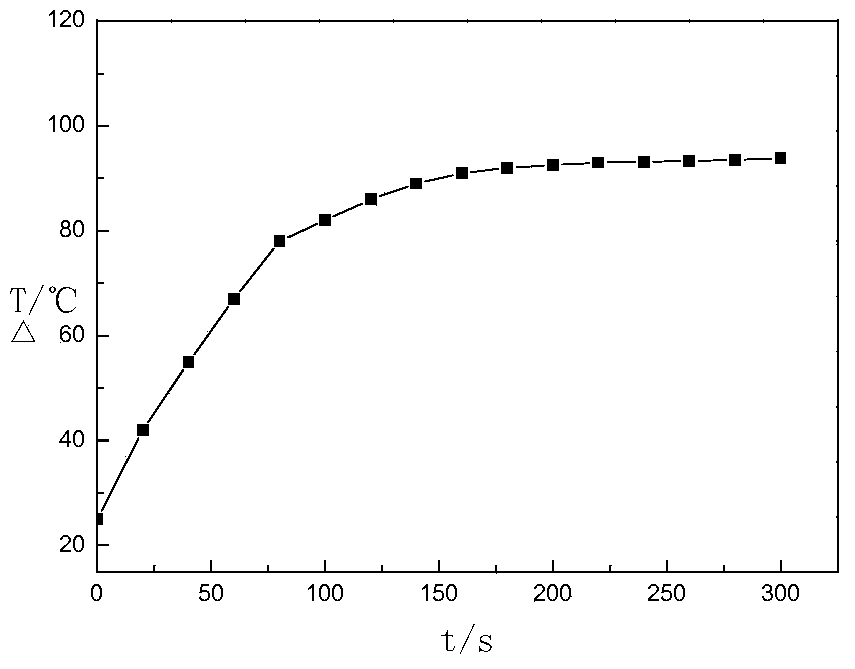

[0024] Embodiment 1 gets 1.81g through the nano-Ni of silane coupling agent KH-550 surface modification 0.5 Zn 0.5 Fe 2 o 4 Add the powder into 12.51g of epoxy resin E-44, stir well and ultrasonically disperse, then add 0.63g of polyamide and aliphatic amine blend curing agent into the epoxy resin, and mix well. The above mixed solution was poured into a mold, and the mold was placed in an alternating magnetic field with a magnetic field strength of 22.7kA / m, an alternating heating current of 275A, and a magnetic field frequency of 250kHz at room temperature for magnetothermal curing.

Embodiment 2

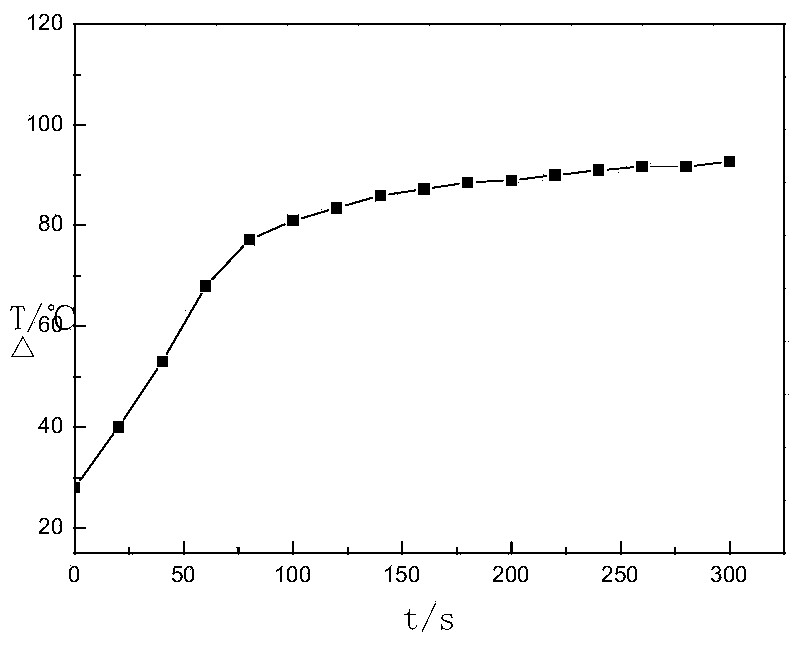

[0025] Embodiment 2 gets 1.49g through the nano-Ni of silane coupling agent KH-550 surface modification 0.5 Zn 0.5 Fe 2 o 4 Add the powder into 15.48g of epoxy resin E-44, stir well and ultrasonically disperse, then add 0.77g of polyamide and aliphatic amine blend curing agent into the epoxy resin, and mix well. The above mixed solution was poured into a mold, and the mold was placed in an alternating magnetic field with a magnetic field strength of 22.7kA / m, an alternating heating current of 275A, and a magnetic field frequency of 250kHz at room temperature for magnetothermal curing.

Embodiment 3

[0026] Embodiment 3 gets 1.08g through the nano-Ni of silane coupling agent KH-550 surface modification 0.5 Zn 0.5 Fe 2 o 4 Add the powder into 11.18g of epoxy resin E-44, stir well and ultrasonically disperse, then add 0.56g of polyamide and aliphatic amine blend curing agent into the epoxy resin, and mix well. The above mixed solution was poured into a mold, and the mold was placed in an alternating magnetic field with a magnetic field strength of 18.9kA / m, an alternating heating current of 230A, and a magnetic field frequency of 250kHz at room temperature for magnetothermal curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com