Wear-resistant and corrosion-resistant mould material

A mold material, corrosion-resistant technology, applied in the field of engineering material processing, to achieve excellent heat transfer performance and heat and humidity resistance, improve service life, and improve the effect of heat conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

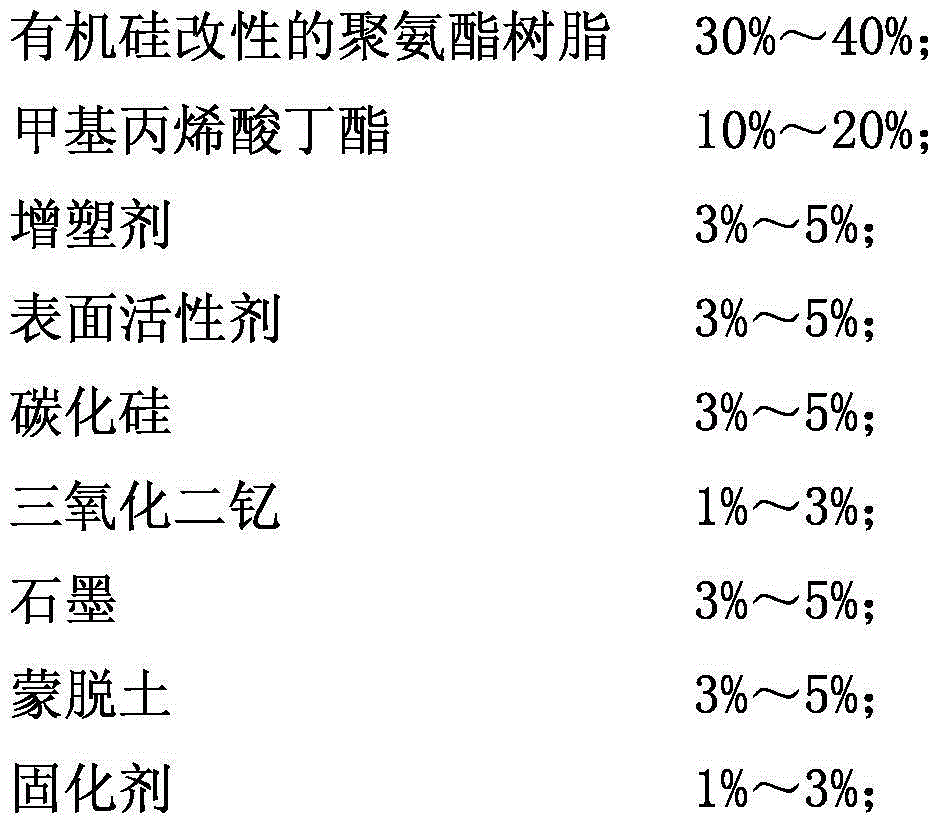

[0023] This case proposes a wear-resistant and corrosion-resistant mold material, which is composed of the following materials in mass percentage:

[0024]

[0025]

[0026] Wherein, plasticizer is preferably selected from butyl phenyl phthalate, dimethoxyethyl phthalate, dipentyl phthalate, dioctyl phthalate, diheptyl phthalate , tributyl phosphate, trioctyl phosphate, triphenyl phosphate, diethyl adipate, dioctyl azelate, dioctyl sebacate, or any combination thereof.

[0027] The surfactant is preferably selected from ethylenediamine, diethylenetriamine, ammonium dodecylbenzenesulfonate or combinations thereof.

[0028] Most of the existing plastic molds use epoxy resin as the base material, but considering the production cost, polyurethane resin is cheaper, and polyurethane r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com