Artificial quartz sheet for ground pavement, and its preparation method

A technology for artificial quartz stone and plate, applied in the field of artificial quartz stone production, can solve the problems of warpage, easy deformation, high water absorption of unsaturated polyester resin, and improve aging resistance, impact resistance, and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

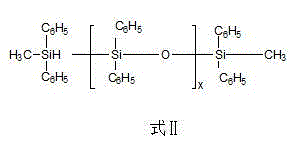

Method used

Image

Examples

Embodiment 1

[0041] formula:

[0042] Silicone resin prepolymer 14.8Kg, organic diluent 13 Kg, toughening agent 1.5 Kg, curing agent 1 Kg, coupling agent 1.5 Kg, antioxidant 0.8 Kg, colorant 1.1 Kg and inorganic silicon filler 66.3 Kg.

[0043] Among them, the silicone resin prepolymer is composed of the following components by weight percentage: 35% of methyl ethoxysilane prepolymer, 16% of methylphenyl silicone resin prepolymer, condensation type silicone resin containing epoxy group Prepolymer 49%;

[0044] The organic diluent is made up of the following components by weight percentage: toluene 20%, xylene 25%, ethyl acetate 55%;

[0045] Toughening agent is made up of the composition of following percentage by weight: dibutyl phthalate 24%, dioctyl phthalate 33%, polyethylene glycol 400 43%;

[0046] The curing agent is composed of the following components by weight percentage: 12% lead naphthenate, 13% iron naphthenate, 30% boron-containing polymethylphenyl silicon nitrogen, 33% mal...

Embodiment 2

[0056] formula:

[0057] Silicone resin prepolymer 13.5Kg, organic diluent 15Kg, toughening agent 1.2Kg, curing agent 1.3Kg, coupling agent 1.5Kg, antioxidant 0.4Kg, colorant 0.9Kg and inorganic silicon filler 66.2Kg.

[0058] The silicone resin prepolymer is a condensation type silicone resin prepolymer containing epoxy groups;

[0059] The organic diluent is ethyl acetate;

[0060] The toughening agent is dioctyl phthalate;

[0061] The curing agent is composed of the following components by weight percentage: maleic anhydride 68%, triethylamine 32%;

[0062] The coupling agent is composed of the following components by weight percentage: N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane coupling agent 33%, bis-(γ-triethoxysilane base)-tetrasulfide 38% and γ-aminopropylmethyldiethoxysilane 29%;

[0063] The anti-aging agent is composed of the following components by weight percentage: 35% of N,N-di(β-naphthyl)-p-phenylenediamine, 45% of styrene phenol, bis-2,2,6,6-tetr...

Embodiment 3

[0071] formula:

[0072] Silicone resin prepolymer 13.4Kg, organic diluent 17Kg, toughening agent 1Kg, curing agent 0.8Kg, coupling agent 1.7Kg, anti-aging agent 0.2Kg, colorant 1.6Kg, inorganic silicon filler 64.3Kg.

[0073] Among them, the silicone resin prepolymer is composed of the following components by weight percentage: 39% of methylphenyl silicone resin prepolymer, 61% of epoxy group-containing condensation type silicone resin prepolymer;

[0074] The organic diluent is made up of the following components by weight: 30% toluene, 70% xylene;

[0075] Toughening agent is made up of the composition of following percentage by weight: dibutyl phthalate 53%, polyethylene glycol 400 47%;

[0076] The curing agent is composed of the following components by weight percentage: 25% of lead naphthenate, 40% of boron-containing polymethylphenylsilica nitrogen, and 35% of maleic anhydride;

[0077] The coupling agent is composed of the following components by weight percentage: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com