Preparation method of zinc oxide-based transparent conducting film glass

A transparent conductive film, zinc oxide-based technology, applied in the direction of coating, etc., can solve the problems of difficult control and complicated process, and achieve the effect of easy operation, simple process and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

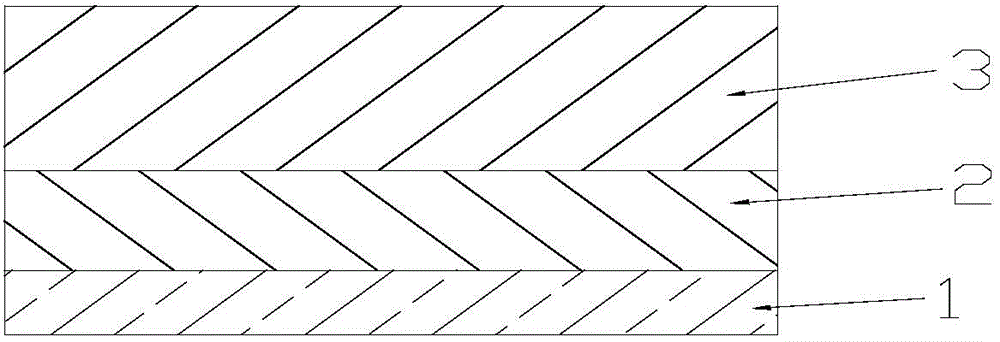

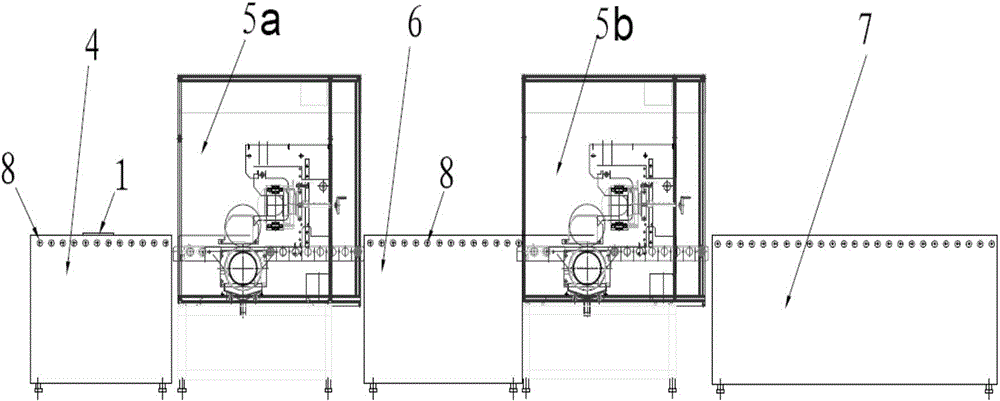

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the glass substrate is 3.2mm ultra-clear glass; using the first liquid phase roll coater, a silicon dioxide interlayer film is plated on the glass surface with tetraethyl orthosilicate hydrolysis precursor; Then, the mixed solution of zinc acetate and aluminum nitrate is coated on the glass surface by using the second liquid-phase roller coater reactor to form a zinc oxide-doped aluminum (AZO) transparent conductive film. The post-treatment temperature of the glass substrate is 510° C., and the post-treatment time is 10 min.

[0037] It has been determined that the thickness of the middle layer is 86nm, the thickness of the AZO transparent conductive layer is 700nm, the sheet resistance of the film layer is 7.2Ω / □, and the carrier concentration of the film layer is 7.9×10 20 / cm 3 , The visible light transmittance of AZO transparent conductive film glass is 83%. Therefore, it can be seen that the AZO transparent conductive film glass has good optic...

Embodiment 2

[0039]In the present embodiment, the glass substrate is 4mm ultra-clear glass; utilize the first liquid-phase roller coater to coat a layer of silicon dioxide interlayer film on the glass surface with the hydrolysis precursor solution of methyl orthosilicate; then The mixed solution of zinc sulfate and tin tetrachloride is coated on the glass surface by using the second liquid-phase roller coater reactor to form a zinc oxide-doped tin (TZO) transparent conductive film. The post-treatment temperature of the glass substrate is 550° C., and the post-treatment time is 13 minutes.

[0040] After measurement, the thickness of the middle layer is 100nm, the thickness of the TZO transparent conductive layer is 682nm, the sheet resistance of the film layer is 7.5Ω / □, and the carrier concentration of the film layer is n is 7.6×10 20 / cm 3 , The visible light transmittance of TZO transparent conductive film glass is 80%. Therefore, it can be seen that the TZO transparent conductive fil...

Embodiment 3

[0042] In this embodiment, the glass substrate is 4mm ultra-clear glass; using the first liquid phase roller coater, a layer of orthosilicate and ethyl orthosilicate mixed hydrolysis precursor is coated on the glass surface The silicon dioxide interlayer thin film; then use the second liquid-phase roll coating machine reactor to coat the mixed solution of zinc chloride and ammonium fluoride on the glass surface to form a zinc oxide fluorine-doped (FZO) transparent conductive film. The post-treatment temperature of the glass substrate is 520° C., and the post-treatment time is 15 minutes.

[0043] After measurement, the thickness of the middle layer is 96nm, the thickness of the FZO transparent conductive layer is 580nm, the sheet resistance of the film layer is 8.9Ω / □, and the carrier concentration of the film layer is n is 6.8×10 20 / cm 3 , The visible light transmittance of FZO transparent conductive film glass is 89%. Therefore, it can be seen that the FZO transparent con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com