Adjustable tool for machining outer cylindrical surface and using method thereof

A technology for machining tools on the outer cylindrical surface, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of complex structure, high price, low efficiency, etc., to increase the rough machining area, improve efficiency, improve The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

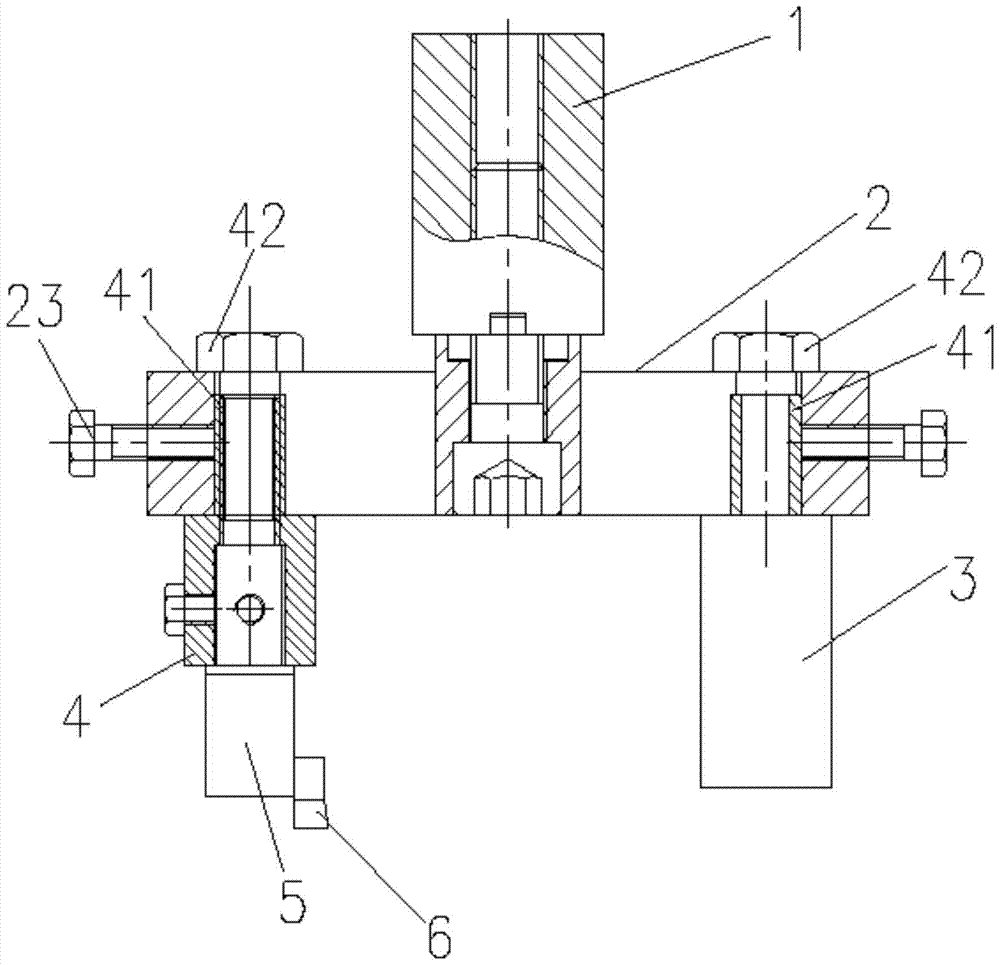

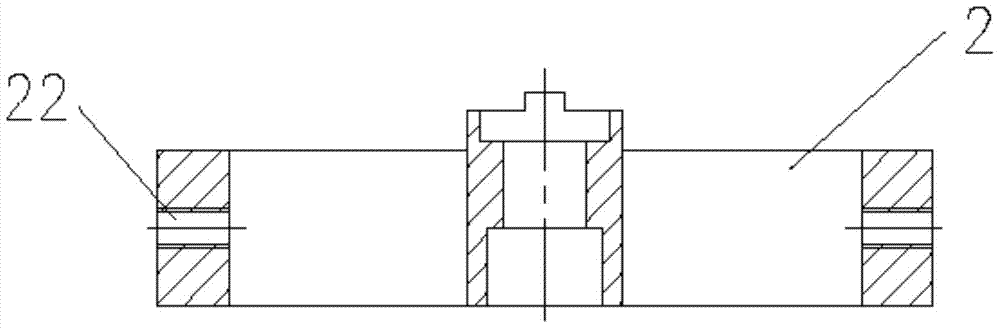

[0027] Such as figure 1 Shown, a kind of adjustable outer cylindrical surface processing cutter comprises a collet connecting rod 1, a slide block 2, a balance weight 3, a cutter head connecting rod 4, a tool holder 5 and a blade 6; One end of rod 1 is connected to the main shaft of the machine tool through a powerful collet handle, and the other end is fixedly connected to the middle of slider 2; one end of cutter head connecting rod 4 is fixedly installed on one end of slider 2 through fixing bolt 42, and the balance weight 3 is fixed and installed through fixing bolt 42 At the other end of the slide block; the other end of the cutter head connecting rod 4 is fixedly connected with a tool holder 5 by a bolt, and a blade 6 is fixedly connected with the tool holder 5, and the blade 6 is rotated towards the axis of the tool.

[0028] The size of the outer circle of the spring clip joint 1 can be adjusted according to the size of the tool holder of different powerful collets on ...

Embodiment 2

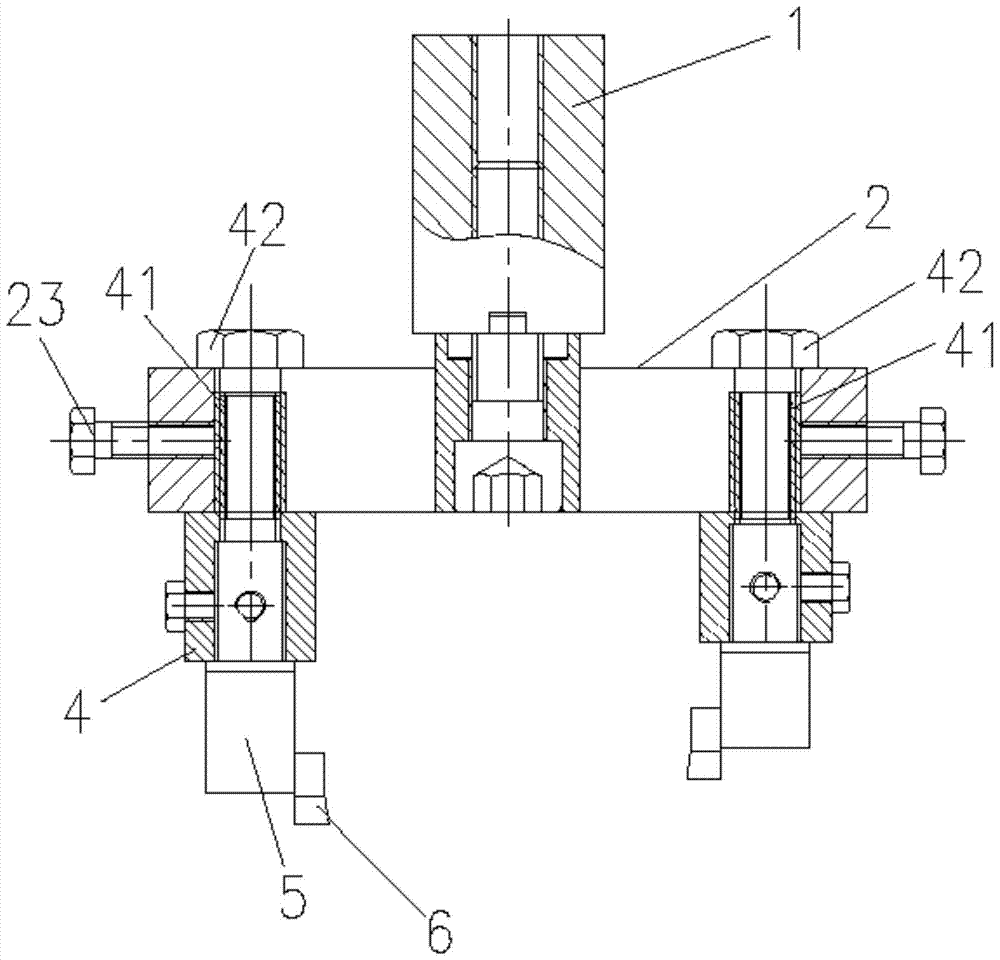

[0035] Such as figure 2 As shown, an adjustable outer cylindrical surface processing tool includes a collet connecting rod 1, a slider 2, two cutter head connecting rods 4, two tool clips 5 and two blades 6; one end of the collet connecting rod 1 The tool handle of the machine tool is connected to the main shaft of the machine tool through a strong chuck, and the other end is fixedly connected to the middle of the slider 2; one end of the two cutter head rods 4 is relatively fixed and installed on both ends of the slider 2 through fixing bolts 42, and the other ends of the two cutter head rods 4 The two tool holders 5 are fixedly connected by bolts, and the two tool holders 5 are fixedly connected with two blades 6, and each blade 6 faces the axis of rotation of the tool.

[0036] When performing rough machining, the balance weight 3 can be replaced by the cutter head connecting rod 4, and then the cutter holder 5 and the blade 6 are connected, and the two blades process the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com