Method to improve apparent mass of film coating

A technology of surface quality and thin film coating, which is applied to the surface coating liquid device, coating, etc., can solve the problems of gravure roll surface groove and mesh clogging, paste roll, uneven coating thickness, etc. Achieve the effects of improving coating stability, lowering temperature, and good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

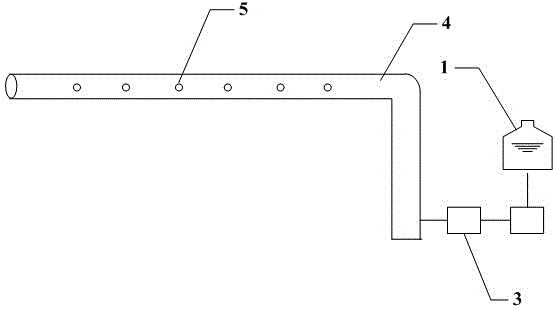

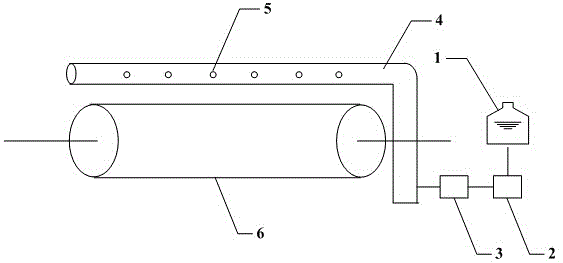

[0027] The present invention adopts known methods to prepare the coating liquid, and the water-based coating liquid is coated on the support body PET by a coating gravure roll, dried, and wound to obtain a coating film with a functional layer.

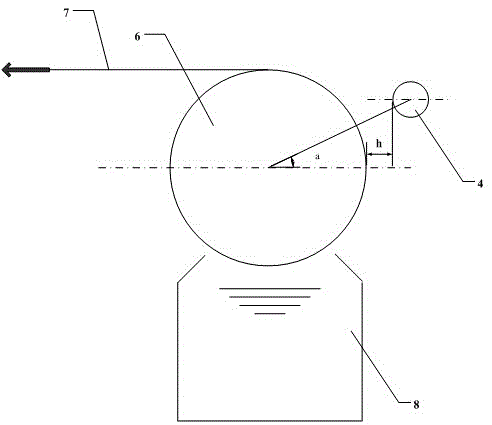

[0028] An ultrasonic humidifying device is arranged on the side where the coating gravure roll 6 returns to the liquid supply chamber, and the spray pipe of the device is arranged in front of the coating gravure roll 6 in the direction of motion, and the angle between the horizontal direction a of the gravure roll is 30°, and the distance h is 10 mm. place; the inner diameter of the spray pipe 4 is 20mm, and spray nozzles 5 with an aperture of 5mm and a hole spacing of 60mm are distributed on its surface. When the coating starts, turn on the power, adjust the frequency of the ultrasonic oscillator 2 to 1.0 MHz, and spray the water mist from the spray nozzle 5 to the surface of the coating gravure roll 6 through the spray tube 4 .

Embodiment 2

[0030] A coating liquid is prepared, and the water-based coating liquid is coated on a support PET by a coating gravure roll, dried, and wound to obtain a coating film with a functional layer.

[0031] An ultrasonic humidifying device is arranged on the side where the coating gravure roll 6 returns to the liquid supply chamber, and the spray pipe of the device is arranged in front of the coating gravure roll 6 in the direction of motion and at an angle of 40° to the horizontal direction a of the gravure roll, and the distance h is 15mm The inner diameter of the spray pipe 4 is 30 mm, and spray nozzles 5 with an aperture of 7 mm and a spacing of 70 mm are distributed on its surface. When the coating starts, turn on the power, adjust the frequency of the ultrasonic oscillator 2 to 1.2 MHz, and spray the water mist from the spray nozzle 5 to the surface of the coating gravure roll 6 through the spray tube 4 .

Embodiment 3

[0033] A coating liquid is prepared, and the water-based coating liquid is coated on a support PET by a coating gravure roll, dried, and wound to obtain a coating film with a functional layer.

[0034] An ultrasonic humidifying device is arranged on the side where the coating gravure roll 6 leaves the liquid supply chamber, and the spray pipe of the device is arranged in front of the coating gravure roll 6 in the moving direction, and the angle between the horizontal direction a of the gravure roll is 45°, and the distance h is 20 mm. The inner diameter of the spray pipe 4 is 35 mm, and spray nozzles 5 with an aperture of 9 mm and a spacing of 80 mm are distributed on its surface. When the coating starts, turn on the power, adjust the frequency of the ultrasonic oscillator 2 to 1.4 MHz, and spray the water mist from the spray nozzle 5 to the surface of the coating gravure roll 6 through the spray tube 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com