Preparation method of noble metal-loaded active carbon material catalyst

An activated carbon and precious metal technology, applied in the field of nanomaterials, can solve the problems of high energy consumption in reduction and heat treatment processes, uncontrolled catalyst morphology, complicated and complicated processes, etc., and achieves easy mass production, easy operation, and simple and effective methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

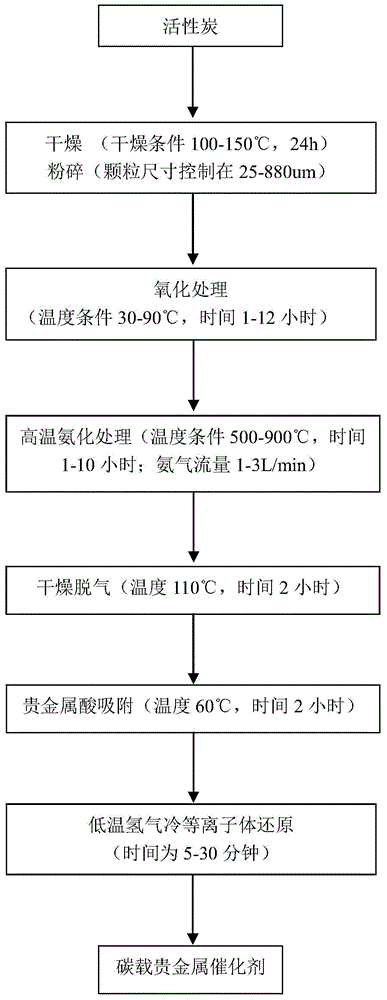

[0024] Such as figure 1 as shown, figure 1 It is a flow chart of the preparation method of the activated carbon material low-temperature in-situ supported reduction noble metal platinum catalyst in Example 1.

[0025] A method for preparing an activated carbon material low-temperature in-situ supported reduction noble metal platinum catalyst, comprising the following steps: placing the activated carbon material in a vacuum drying oven, and drying at 100°C for at least 24 hours. Put the dried activated carbon material in a flask, add excess 65% concentrated nitric acid solution and keep stirring, keep it in an oil bath at 30°C for 12 hours, then vacuum filter, wash and dry to obtain the activated carbon material treated with nitric acid oxidation ; Put the oxidized and dried carbon powder in the material boat, put the material boat into the tube furnace, vacuumize the furnace tube, and program the temperature to 400 °C under nitrogen atmosphere, the flow rate of nitrogen gas i...

Embodiment 2

[0027] A method for preparing an activated carbon material low-temperature in-situ supported reduction noble metal platinum catalyst, comprising the following steps: placing the activated carbon material in a vacuum drying oven, and drying at 100°C for at least 24 hours. Put the dried activated carbon material in a flask, add excess 0.5% potassium permanganate solution and keep stirring, keep it in an oil bath at 60°C for 6 hours, then vacuum filter, wash and dry to obtain nitric acid oxidation treated Activated carbon material: put the oxidized and dried carbon powder in the material boat, put the material boat into the tube furnace, vacuumize the furnace tube, and program the temperature to 400°C under nitrogen atmosphere, and the flow rate of nitrogen gas is 1L / min , when the temperature reaches 400°C, switch the nitrogen gas to ammonia gas, the flow rate of the ammonia gas is 1L / min, the heating rate is 5°C / min, keep at 700°C for 4 hours, then cool naturally, after the high...

Embodiment 3

[0029] A method for preparing an activated carbon material low-temperature in-situ supported reduced noble metal palladium catalyst, comprising the following steps: placing the activated carbon material in a vacuum drying oven, and drying at 100°C for at least 24 hours. Place the dried activated carbon material in a flask, add excess 30% hydrogen peroxide solution and keep stirring, keep in an oil bath at 90°C for 2 hours, then vacuum filter, wash and dry to obtain nitric acid oxidation treated activated carbon material; Put the oxidized and dried carbon powder in the material boat, put the material boat into the tube furnace, evacuate the furnace tube, and program the temperature up to 400°C under nitrogen atmosphere. The flow rate of nitrogen gas is 1L / min, and the temperature reaches After 400°C, switch from nitrogen to ammonia. The flow rate of ammonia flow is 1L / min, and the heating rate is 5°C / min. After holding at 900°C for 1 hour, cool naturally. After high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com