Method for comprehensively utilizing cinnamomum longepaniculatum leaves

A technology of camphor leaves and volatile oil, applied in the field of camphor leaves utilization, can solve the problems of wasting resources, less research on development and utilization methods, low comprehensive utilization rate of raw materials, etc., and achieves the effects of reducing damage and promoting sustainable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

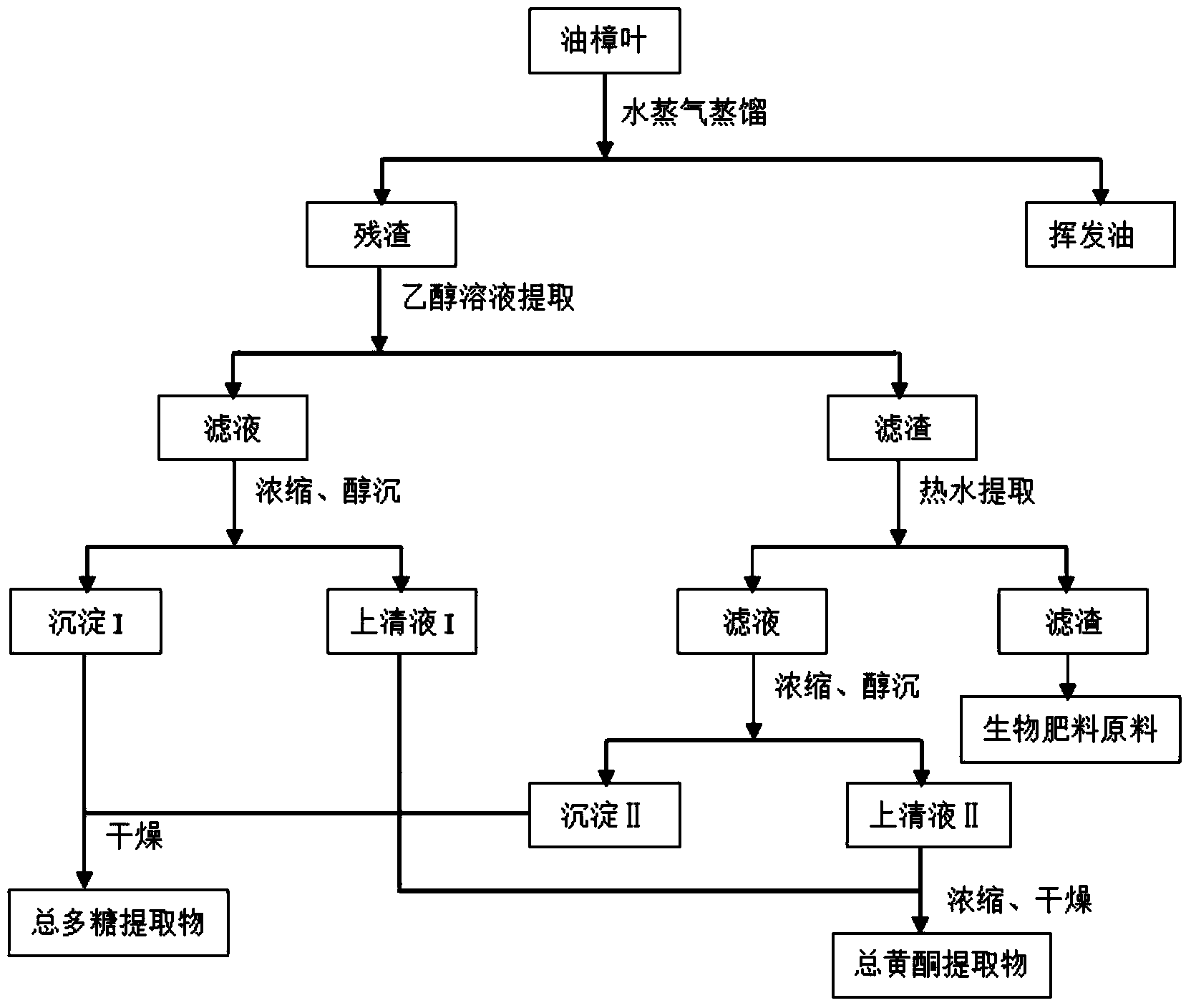

[0013] Embodiment 1: as figure 1 As shown, 1 kg of dried camphor leaves were distilled over water for 2 hours, the distillation condensate was collected, and the oil and water were separated to obtain 48.2 mL of volatile oil.

[0014] Dry the camphor leaf residue after extracting the volatile oil, pulverize it, pass through an 80-mesh sieve, add the camphor leaf residue into an ethanol solution with a volume fraction of 50% according to the mass ratio of material to liquid 1:15, soak for 20 minutes, and extract at 90°C for 120 minutes , filter, the filter residue is for subsequent use, concentrate the filtrate, add high-concentration ethanol solution to the concentrated solution, make the alcohol content reach 80%, let it stand overnight, centrifuge, collect the precipitate I, and adopt the phenol sulfuric acid method to record the total polysaccharide in the precipitate I as 33.12g, Collect the supernatant I and use NaNO 2 -Al(NO 3 ) 3 -NaOH colorimetric method records the...

Embodiment 2

[0017] Embodiment 2: as figure 1 As shown, 1kg of dried camphor leaves were distilled by direct steam for 2h, the distillation condensate was collected, and the oil and water were separated to obtain 50.2mL of volatile oil.

[0018] Dry the camphor leaf residue after extracting the volatile oil, crush it, pass through a 60-mesh sieve, add the camphor leaf residue to an ethanol solution with a volume fraction of 40% according to the mass ratio of material to liquid 1:10, soak for 10 minutes, and extract at 80°C for 60 minutes , filter, the filter residue is for subsequent use, concentrate the filtrate, add high-concentration ethanol solution to the concentrated solution, make the alcohol content reach 80%, leave standstill overnight, centrifuge, collect the precipitate I, adopt the phenol sulfuric acid method to record the total polysaccharide in the precipitate I as 36.04g, Collect the supernatant I and use NaNO 2 -Al(NO 3 ) 3 -NaOH colorimetric method records the total fla...

Embodiment 3

[0021] Embodiment 3: as figure 1 As shown, 1kg of dried camphor leaves were distilled by steam diffusion for 2h, the distillation condensate was collected, and the oil and water were separated to obtain 53.2mL of volatile oil.

[0022] Dry the camphor leaf residue after extracting the volatile oil, crush it, pass through a 100-mesh sieve, add the camphor leaf residue to an ethanol solution with a volume fraction of 70% according to the mass ratio of material to liquid 1:20, soak for 30 minutes, and extract at 100°C for 180 minutes , filter, the filter residue is for subsequent use, concentrate the filtrate, add high-concentration ethanol solution to the concentrated solution, make the alcohol content reach 80%, let stand overnight, centrifuge, collect the precipitate I, adopt the phenol sulfuric acid method to record the total polysaccharide in the precipitate I as 12.32g, Collect the supernatant I and use NaNO 2 -Al(NO 3 ) 3 -NaOH colorimetric method records the total flav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com