Glass eel late stage compound feed

A technology of compound feed and glass eel, which is applied in animal feed, animal feed, climate change adaptation, etc., can solve the problems of bloodworm cleaning and vomiting, economic loss of farmers, and lax disinfection, etc., to promote healthy and rapid growth , Improving immunity and survival rate, and the effect of improving feed conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

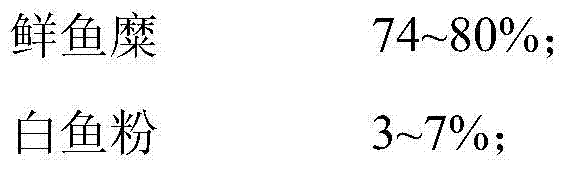

[0049] The glass eel late stage compound feed, its raw material components and their weight percentages are as follows:

[0050]

[0051] The various raw material components are mixed to form a compound feed.

[0052] The compound feed in the later stage is a mixture made of each component according to the processing method of surimi. The production process during processing is as follows: fresh fish is beaten into surimi to obtain fresh surimi, and then the remaining raw material groups mentioned above are added. Mix evenly to obtain the finished product.

Embodiment 2

[0054] The glass eel late stage compound feed, its raw material components and their weight percentages are as follows:

[0055]

[0056] The various raw material components are mixed to form a compound feed.

[0057] The compound feed in the later stage is a mixture made of each component according to the processing method of surimi. The production process during processing is as follows: fresh fish is beaten into surimi to obtain fresh surimi, and then the remaining raw material groups mentioned above are added. Mix evenly to obtain the finished product.

Embodiment 3

[0059] The glass eel late stage compound feed, its raw material components and their weight percentages are as follows:

[0060]

[0061]

[0062] The various raw material components are mixed to form a compound feed.

[0063] The compound feed in the later stage is a mixture made of each component according to the processing method of surimi. The production process during processing is as follows: fresh fish is beaten into surimi to obtain fresh surimi, and then the remaining raw material groups mentioned above are added. Mix evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com