Valve pipe fitting gas tightness and machine vision comprehensive examination machine

A technology of machine vision inspection and machine vision, applied in liquid tightness measurement using liquid/vacuum degree, detecting the appearance of fluid at the leak point, optical testing for flaws/defects, etc., can solve time-consuming, reduce production efficiency, function Singleness and other issues, to save time and manpower, improve quality grades, and increase economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

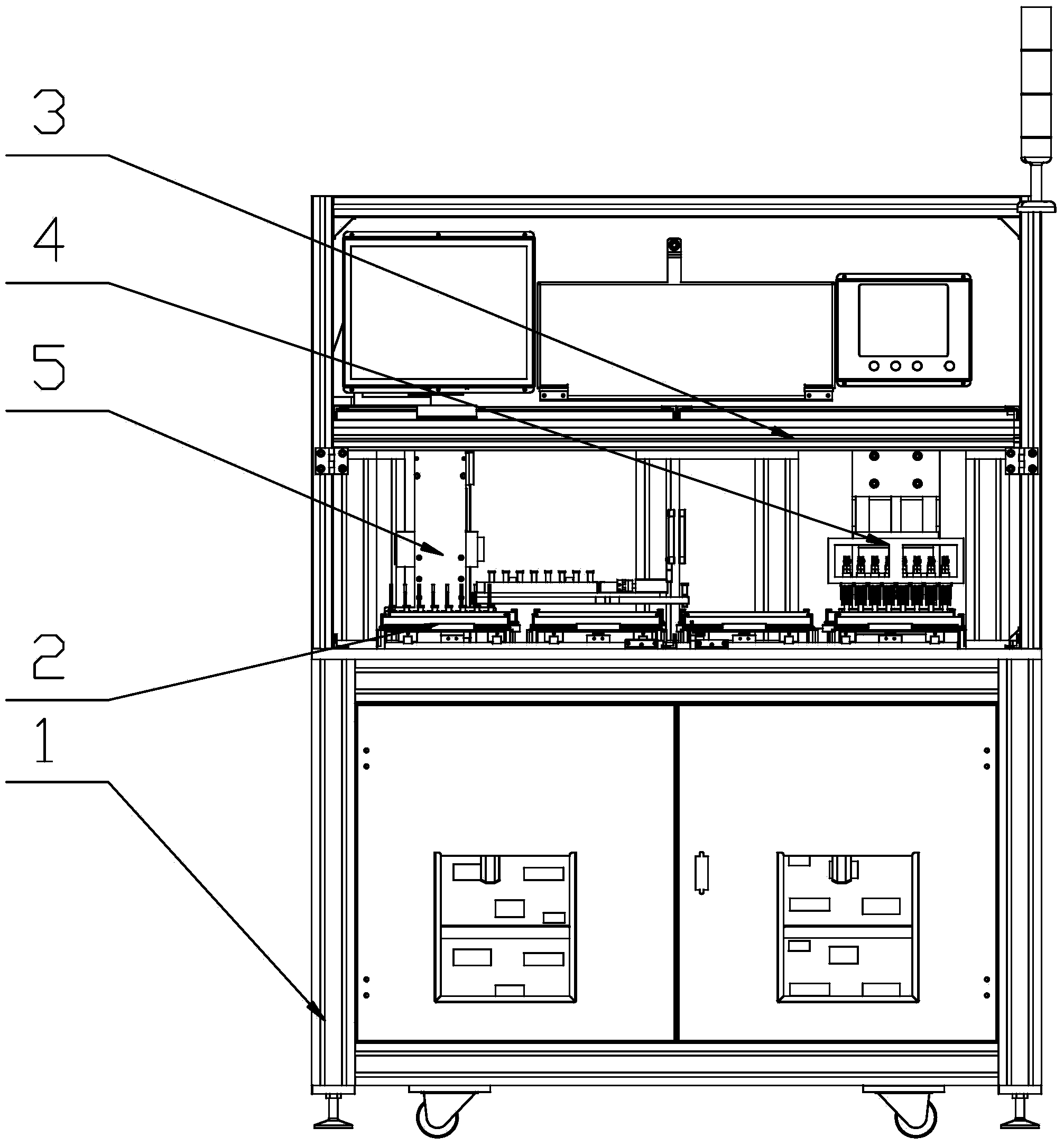

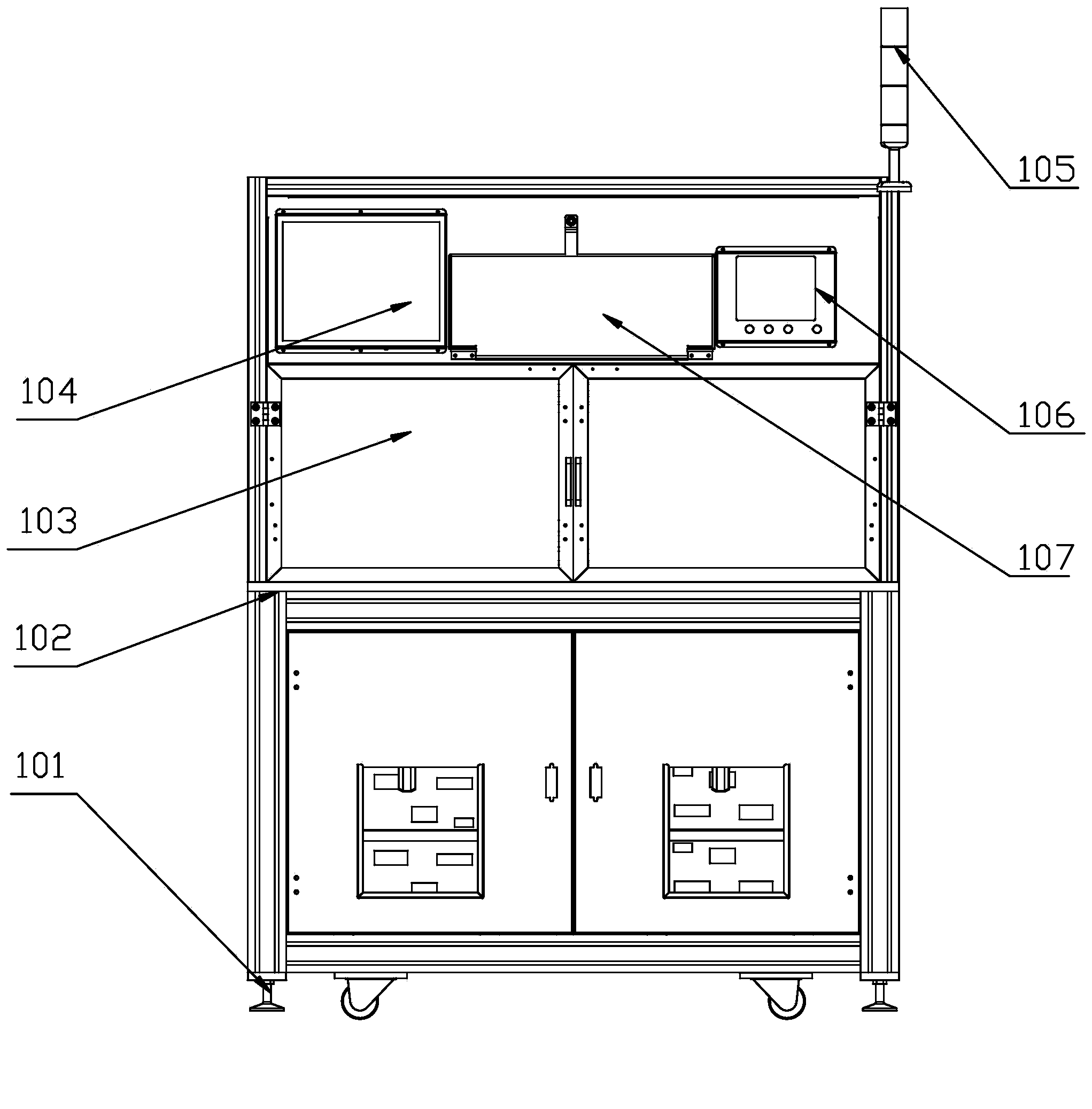

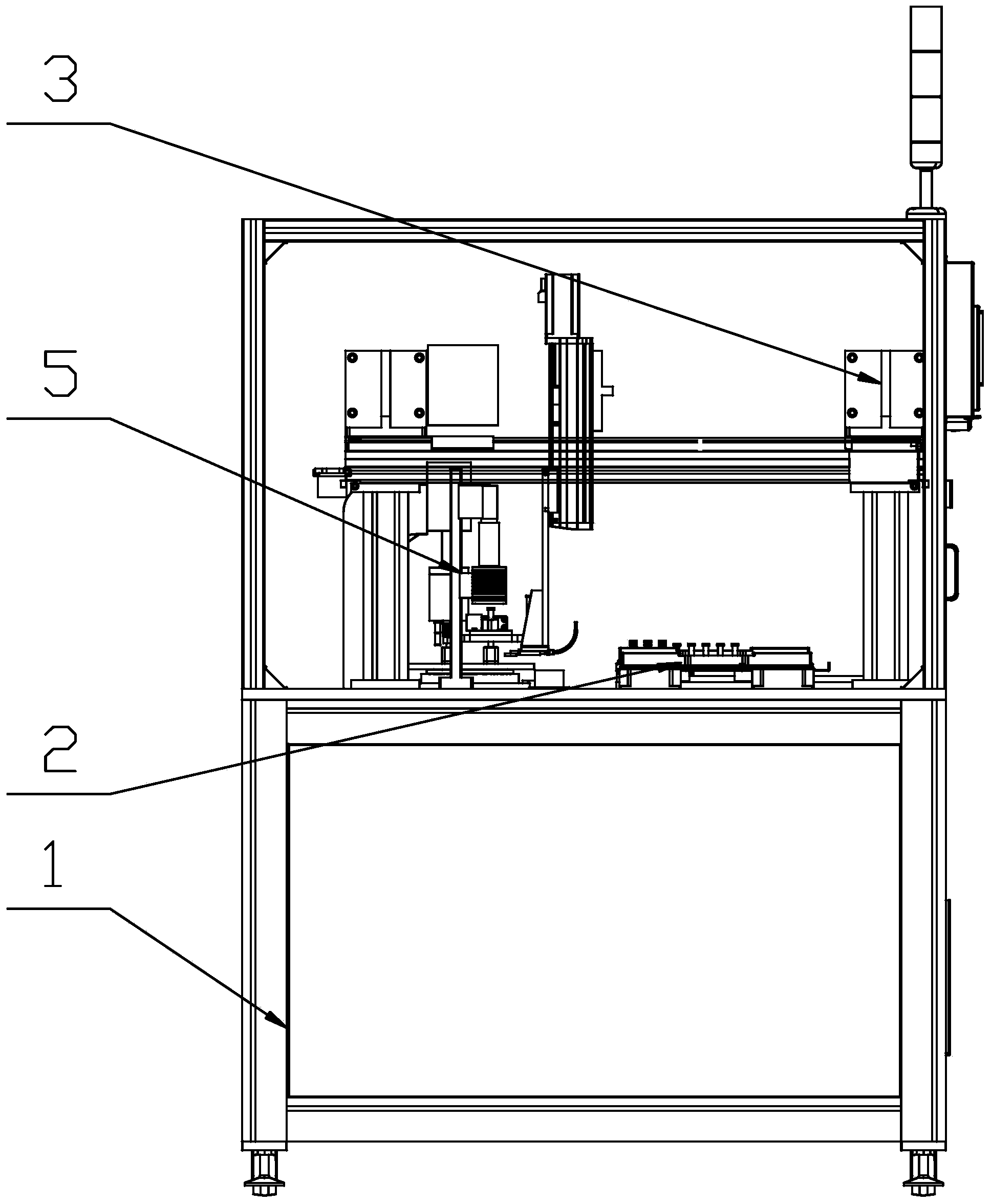

[0028] Such as Figure 1 to Figure 10 As shown, the airtightness and machine vision comprehensive inspection machine for valves and pipe fittings includes a cabinet body 1, on which a tray fixing module 2, a mobile conveying module 3, an airtightness detection mechanism 4 and a machine vision detection mechanism 5 are arranged. A controller, a keyboard 107, a display 104 and an alarm indicator light 105 are also set on the cabinet 1, wherein a touch screen 106 is set on the controller.

[0029] The cabinet body 1 is divided into an upper working layer and a lower storage layer. The upper working layer of the cabinet body 1 is further divided into upper and lower layers. The controller, keyboard 107 and display 104 are place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com