A calibration device for measuring instrument of steel protective layer

A technology of a steel bar protective layer and a calibration device, which is applied in the field of detection and calibration, can solve the problems that the steel bar cannot be well protected, the steel bar is easily corroded and oxidized, and is inconvenient to manufacture and use, and achieves easy purchase and simple and convenient calibration process. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

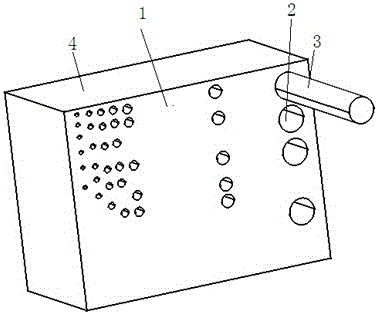

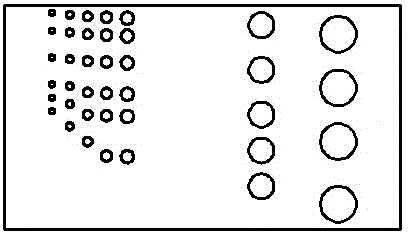

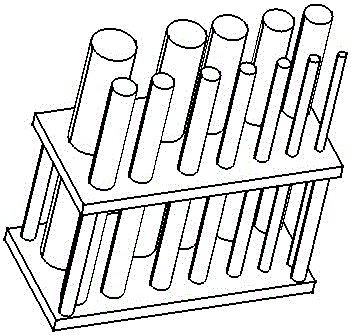

[0023] Such as Figure 1~Figure 2 As shown, a calibration device for steel bar protective layer measuring instrument includes a protective layer standard block 1 and a standard round bar 3. The protective layer standard block 1 is made of non-magnetic material and has a square structure. The upper end surface is provided with serialized through holes 2 and The calibration work plane 4 is set on the side, and the standard round rod 3 is a series of cylindrical rods. The standard round rod 3 is made of the same material as the steel bar, placed in the corresponding through hole 2, and a protective layer standard block with serialized through holes is used. And serialized standard round rods, which can realize the calibration of steel bar cover thickness measuring instruments, the calibration process is simple and convenient, and the calibration results are accurate and effective; the calibration device has a simple structure.

[0024] The protective layer standard block 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com