Preparation method of high-temperature creep resistant grounding substrate for semiconductor equipment

A grounded substrate, high temperature resistance technology, applied in semiconductor/solid-state device manufacturing, coating, fusion spraying, etc., can solve the problem of insufficient high temperature creep resistance of grounded substrates, achieve low porosity and high deposition efficiency , the effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

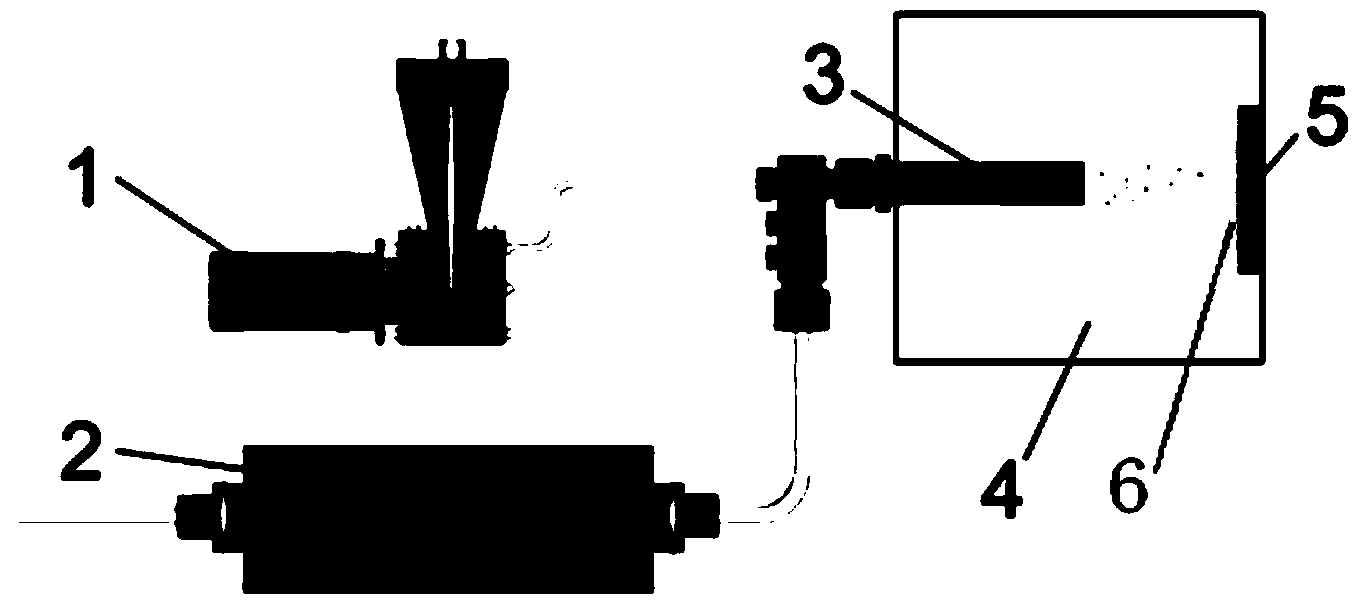

[0028] like Figure 1~5 Shown, a kind of preparation method of high temperature creep resistance ground substrate for semiconductor equipment, comprises the following steps:

[0029] (1) Pre-treatment of the substrate 6 of the grounded substrate: use a nickel-based alloy of 620×64×0.2mm as the substrate 6, and carry out texture treatment on the surface of the substrate 6. The texture treatment process parameters are: 320# sandpaper polishing, removing the carbon layer on the surface of the substrate 6; then cleaning the substrate 6 with absolute ethanol;

[0030] (2) cold spray system comprises spray equipment, spray booth 4 and special fixture 5, and described special fixture 5 is arranged in described spray booth 4, and described substrate 6 is placed on the special fixture 5 of cold spray system; Spray equipment Including intake pipe, heater 2, powder feeder 1 and supersonic nozzle 3, one end of the intake pipe is connected to the high-pressure air source, and the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com