High temperature cementing material system and composition

A cementing and systemic technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems affecting the production and safety of oil and gas wells, formation sealing failure, strength decline, etc., to solve strength decline and reduce emissions The effect of stability of quantity and high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Composition of high temperature cementing material system

[0029] A high-temperature cementing material system can be composed of the following oxides, etc., and the mass fraction of each substance is specifically: SiO 2 51.4 parts, Al 2 o 3 9.8 parts for CaO, 30.2 parts for CaO, CaCO 3 5.6 parts, ZrO 2 1.2 parts for ZnO, 1.0 parts for LiBO 2 ·8H 2 O is 0.8 parts.

Embodiment 2

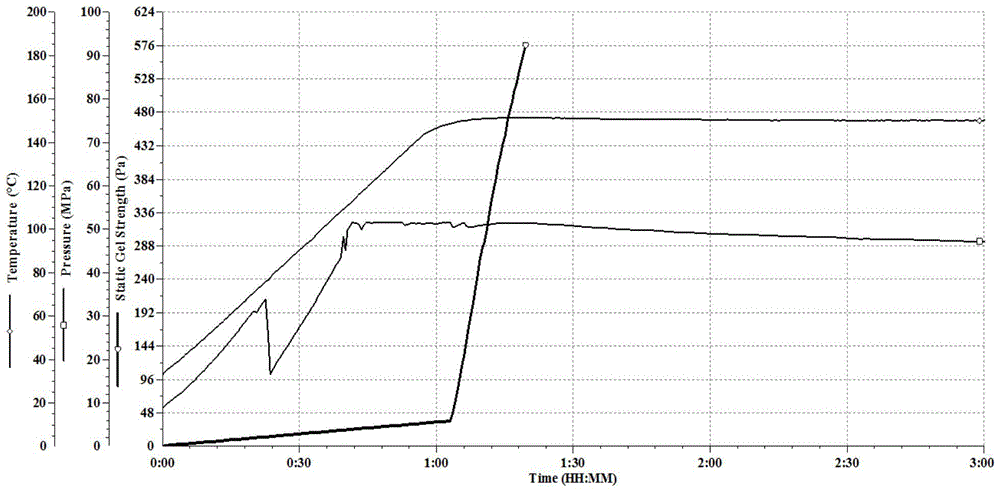

[0030] Example 2: Performance test of high temperature cementing material system slurry

[0031] Taking the high-temperature cementing material system in Example 1 as the test object, first weigh and mix the solid dry ash component and the liquid water component of the high-temperature cementing material system for slurry preparation, and then mix them according to the standard GB / T 19139-2003 "Oil Well Cement Test Method" Prepare the slurry. The test results are shown in Table 1.

[0032] Table 1. Paddle body performance of high temperature cementing material system

Embodiment 3

[0034] Example 3: Compressive Strength Test of High Temperature Cementing Material System

[0035] Taking the high-temperature cementing material system in Example 1 as the test object, first weigh and mix the solid dry ash component and the liquid water component of the high-temperature cementing material system for slurry preparation, and then mix them according to the standard GB / T 19139-2003 "Oil well cement test method" prepares slurry, and measures compressive strength after high temperature and high pressure curing. The test results are shown in Table 2.

[0036] Table 2 Compressive strength performance of high temperature cementing material system

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com