NBR/PVC elastomer by taking LNBR as plasticizer and preparation method of elastomer

A technology of plasticizer and elastomer, which is applied in the field of NBR/PVC elastomer and its preparation, can solve the problems that have not been reported in the research, and achieve the effects of good oil resistance, improved compression performance, and reduced Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

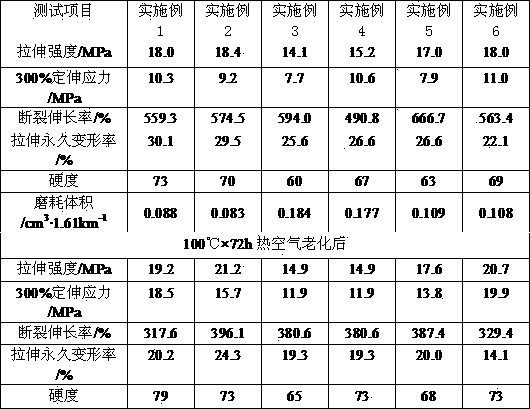

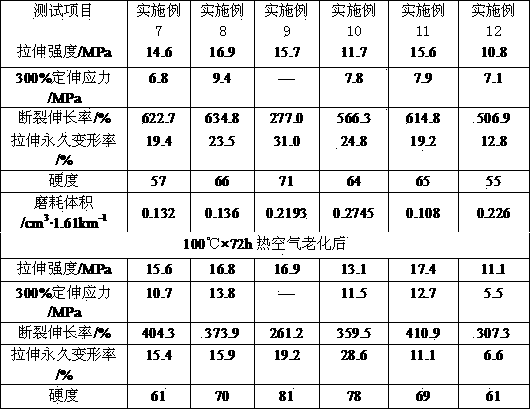

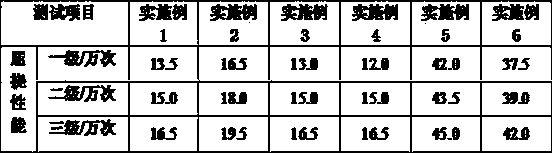

Examples

Embodiment 1

[0024] Example 1 According to the following parts by mass: NBR: 70 parts, PVC: 30 parts, carbon black (N330): 50 parts, LNBR: 30 parts, RD: 1.5 parts, 4010NA: 1.5 parts, sulfur: 1.2 parts, DCP: 0.5 parts, CZ: 1.2 parts, TMTD: 0.3 parts, stabilizer: 1.8 parts, ZnO: 5.0 parts, stearic acid: 1.5 parts.

[0025] A kind of NBR / PVC elastomer with LNBR described in the present embodiment as plasticizer, the preparation steps of its compounded rubber and its vulcanized rubber:

[0026] (1) NBR mastication: masticate NBR on an open rubber mixer, and add anti-aging agent to mix evenly;

[0027] (2) NBR / PVC blending: Heat the plastic mixer to 150~160°C, put the PVC / stabilizer evenly mixed with a high-mix mixer on the roller of the plastic mixer for plasticization, and when it reaches the plasticized state Add NBR for blending, mix evenly and then slice, cool for later use;

[0028] (3) Preparation of mixed rubber: put the NBR / PVC blended rubber obtained in step (2) on the roller of the...

Embodiment 2

[0031] Example 2 According to the following parts by mass: NBR: 70 parts, PVC: 30 parts, carbon black (N330): 30 parts, LNBR: 30 parts, RD: 1.5 parts, 4010NA: 1.5 parts, sulfur: 1.2 parts, DCP: 0.5 parts, CZ: 1.2 parts, TMTD: 0.3 parts, stabilizer: 1.8 parts, ZnO: 5.0 parts, stearic acid: 1.5 parts. The difference between the ratio of this example and Example 1 is that 30 parts of carbon black (N330) are used.

[0032] The preparation method and performance testing standard of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0033] Example 3 Ingredients are prepared according to the following parts by mass: NBR: 70 parts, PVC: 30 parts, carbon black (N220): 30 parts, LNBR: 30 parts, RD: 1.5 parts, 4010NA: 1.5 parts, sulfur: 1.2 parts, DCP: 0.5 parts, CZ: 1.2 parts, TMTD: 0.3 parts, stabilizer: 1.8 parts, ZnO: 5.0 parts, stearic acid: 1.5 parts. The difference between the ratio of this example and Example 1 is that 30 parts of carbon black (N220) are used.

[0034]The preparation method and performance testing standard of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com