Two-stage material-feeding random gradually-varied butylbenzene co-polymer and preparation method thereof

A styrene-butadiene copolymer and gradient copolymerization technology, applied in the field of random gradient styrene-butadiene copolymer and its preparation, can solve the problems of difficulty in alternating control, complicated process, long feeding time, etc., and achieve better toughening effect and preparation Simple method and increased toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

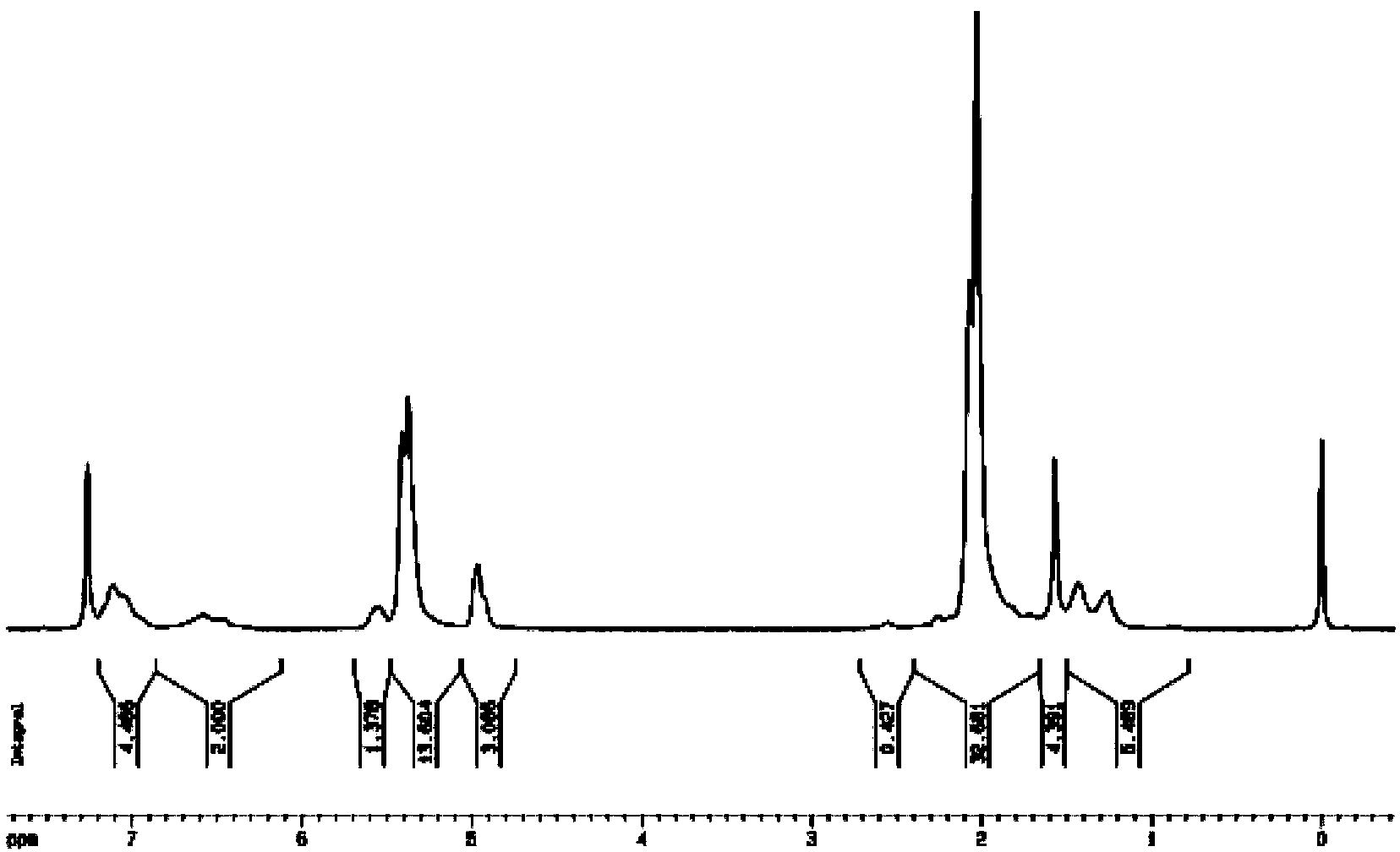

Embodiment 1

[0040] In a 5L jacketed stainless steel polymerization kettle replaced with nitrogen, introduce 2500mL of purified cyclohexane, add 0.39gTHF and 4mmol of n-butyllithium and stir, heat up to 70-80°C with jacketed hot water, and mix for 22.5 g styrene and 225g butadiene are evenly distributed, and the feeding time is controlled to be 20min. They are added to the polymerization kettle at a uniform speed for the first stage of polymerization until the monomer reaction is complete, and then 52.5g of styrene is added for the second stage of polymerization until the monomer is reacted. complete, 0.18 g of ethanol was added to terminate the polymerization reaction. Put the glue out of the polymerization kettle, add 0.75g of antioxidant 1076 and 0.75g of antioxidant 168, stir evenly, and conduct drying treatment after water precipitation and coagulation to obtain dry polymer glue. GPC chromatographic test obtains that the number-average molecular weight of this polymer is 75000, and th...

Embodiment 2

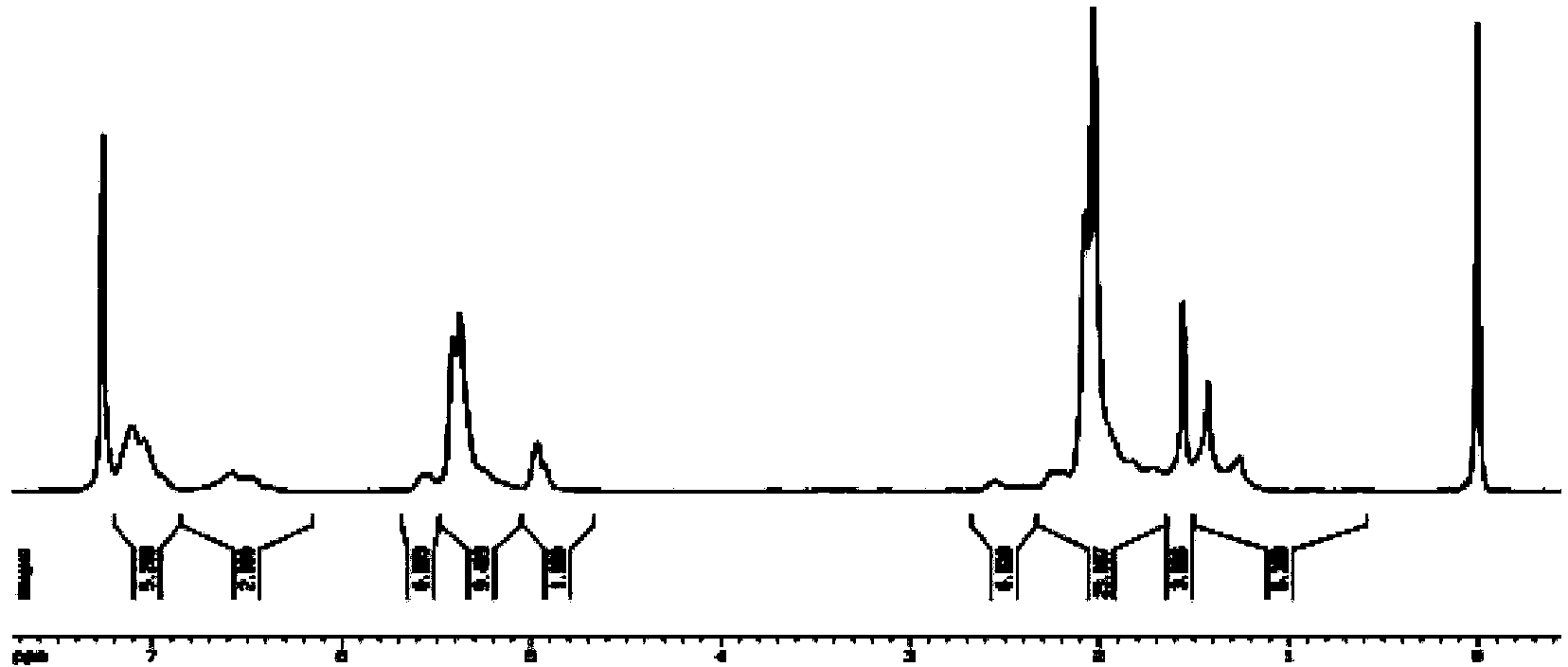

[0047] In a 5L jacketed stainless steel polymerization kettle replaced with nitrogen, introduce 2500mL of purified cyclohexane, add 0.39g THF and 2mmol n-butyllithium and stir, heat up to 70-80°C with jacketed hot water, and Mix 30.0g styrene and 195g butadiene monomer evenly, control the feeding time at 25 minutes, carry out the first stage of polymerization reaction until the monomer reaction is complete, then add 75.0g styrene polymerization, until the monomer reaction is complete, add 0.09g Ethanol terminates the polymerization reaction. Put the glue out of the polymerization kettle, add 0.75g of antioxidant 1076 and 0.75g of antioxidant 168, stir evenly, and conduct drying treatment after water precipitation and coagulation to obtain dry polymer glue. The number-average molecular weight of the polymer is 150,000, the content of polymer block styrene is 25.0% of the total weight ratio of monomers, the content of mixed styrene in butadiene is 10.0% of the total weight ratio...

Embodiment 3

[0063] In a 5L jacketed stainless steel polymerization kettle replaced with nitrogen, introduce 2500mL of purified cyclohexane, add 0.39g THF and 1mmol n-butyllithium and stir, heat up to 70-80°C with jacketed hot water, and Mix 30.0g styrene and 195g butadiene monomer evenly, control the feeding time at 25 minutes, carry out the first stage of polymerization reaction until the monomer reaction is complete, then add 75.0g styrene polymerization, until the monomer reaction is complete, add 0.09g Ethanol terminates the polymerization reaction. Put the glue out of the polymerization kettle, add 0.75g of antioxidant 1076 and 0.75g of antioxidant 168, stir evenly, and conduct drying treatment after water precipitation and coagulation to obtain dry polymer glue. The number-average molecular weight of the polymer is 300,000, the content of polymer block styrene is 35.0% of the total weight ratio of monomers, the content of mixed styrene in butadiene is 10.0% of the total weight ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com