A deep-water composite structural acoustic array and sound transmission method based on the array

A composite structure and acoustic technology, which is applied in the field of deep-water composite structure acoustic arrays, can solve the problems of poor hydrostatic pressure resistance of acoustic arrays, poor reliability and anti-collision performance of waterproof and sound-permeable rubber layers, and expand engineering applications. range, the effect of improving electrical insulation properties and shielding performance, improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

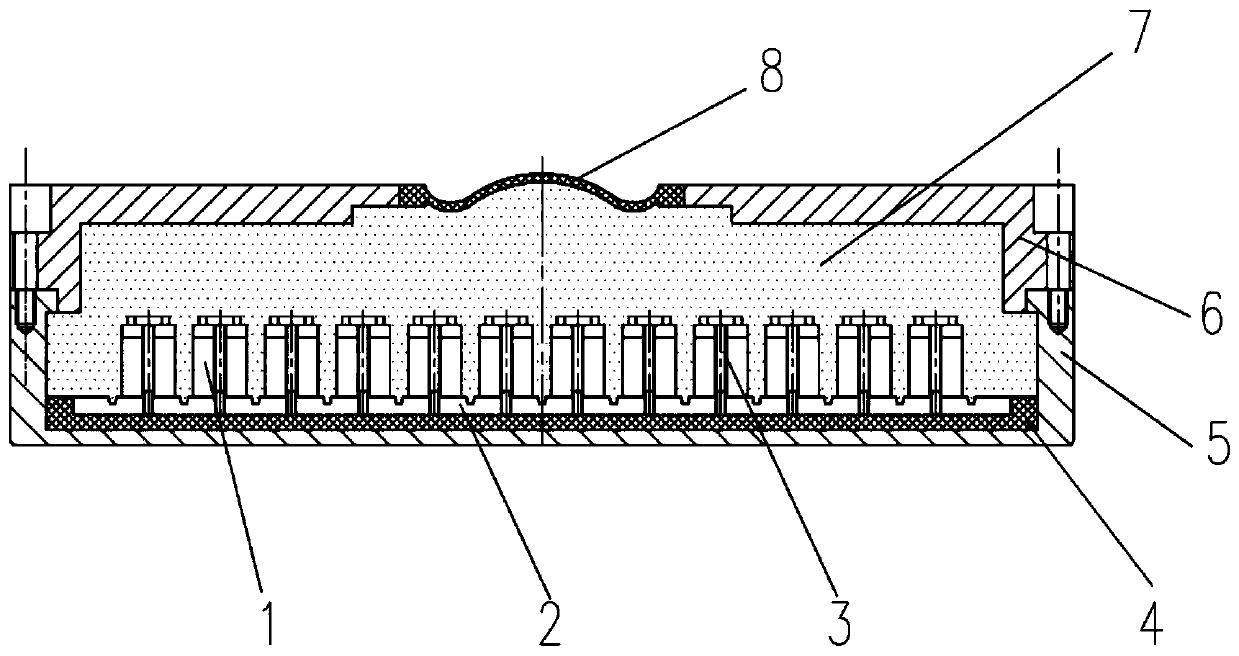

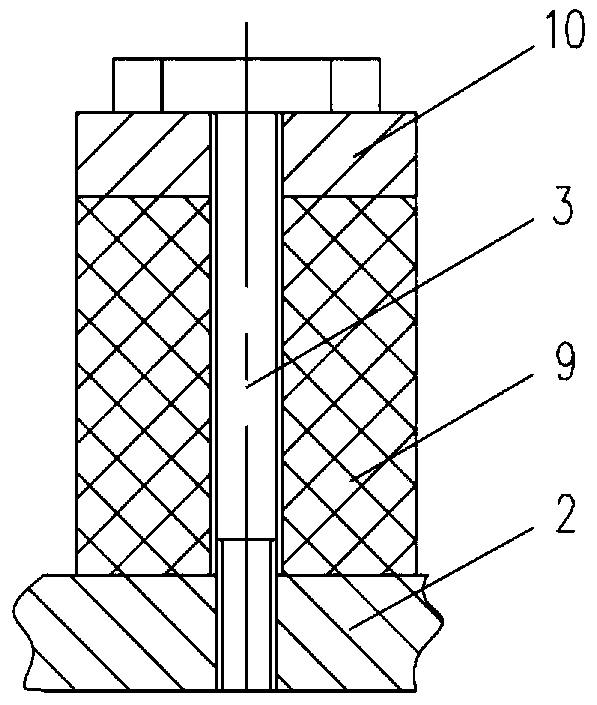

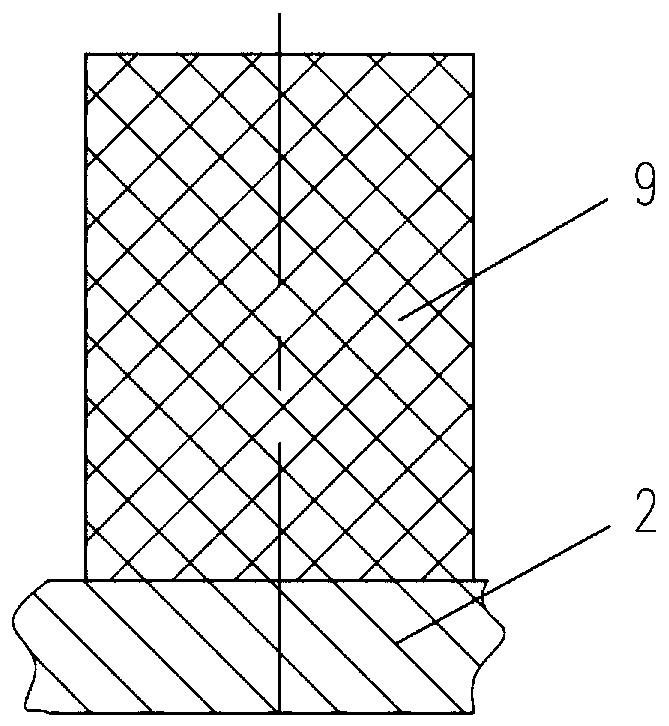

[0034] The upper shell and the lower shell form an axisymmetric cylindrical shell. The bottom surface of the inner cavity of the axisymmetric cylindrical shell is provided with a three-layer composite structure of front radiation plate 2-shock isolation and decoupling layer 4-lower shell 5. The three-layer composite structure As an acoustic sound-permeable window, the unit 1 is fixed in the front radiation plate 2 of the acoustic sound-permeable window to realize a sound-permeable strategy different from the prior art.

Embodiment 2

[0036] The pressure balance window 8 and the filling liquid 7 are used, so that the water pressure outside the matrix is transmitted to the filling liquid inside through the rubber structure of the pressure balance window 8, and the pressure inside and outside the acoustic matrix is kept in balance by utilizing the incompressibility of the filling liquid 7. The ability to withstand hydrostatic pressure of the acoustic array is greatly improved, making it possible for the acoustic array to work in a deep water environment, and expanding the engineering application range of the array, so the following embodiments are provided.

[0037] The present invention provides an acoustic array of deep water composite structure, the acoustic array includes a lower shell 5, an upper shell 6, a shock-isolation and decoupling layer 4, a front radiation plate 2, a basic element 1, a prestressed screw 3, a pressure balance Window 8 and filling liquid 7, the lower shell 5 has a thin-walled me...

Embodiment 3

[0043] Such as figure 1 As shown, the lower shell 5 and the upper shell 6 are processed into an axisymmetric cylindrical shell made of titanium alloy material, and the open ends of the two cylindrical shells are butted to form a cavity for accommodating the element 1. The lower surface of the lower shell 5 (That is, the bottom surface of the inner cavity of the axisymmetric cylindrical shell) should be processed into a thinner wall thickness, such as 5mm thickness; an O-ring is installed between the two shells to ensure watertightness, and 20 M10 titanium alloy screws are axially tightened to form a hermetic seal lumen structure. The front radiant plate 2 is processed into a 10mm thick disc shape with titanium alloy material. The upper surface is processed with 2mm wide and 3mm deep grooves. 96 square bosses are formed between the grooves. The center of the bosses is processed with an internal thread hole. The specific thickness and diameter of the front radiating plate 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com