Air check valve device for exhaust pipe of automobile

A technology of automobile exhaust and check valves, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve the problems of engine exhaust gas not up to standard, achieve the goal of improving exhaust emission conditions, improving accuracy, and avoiding excessive consumption and waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

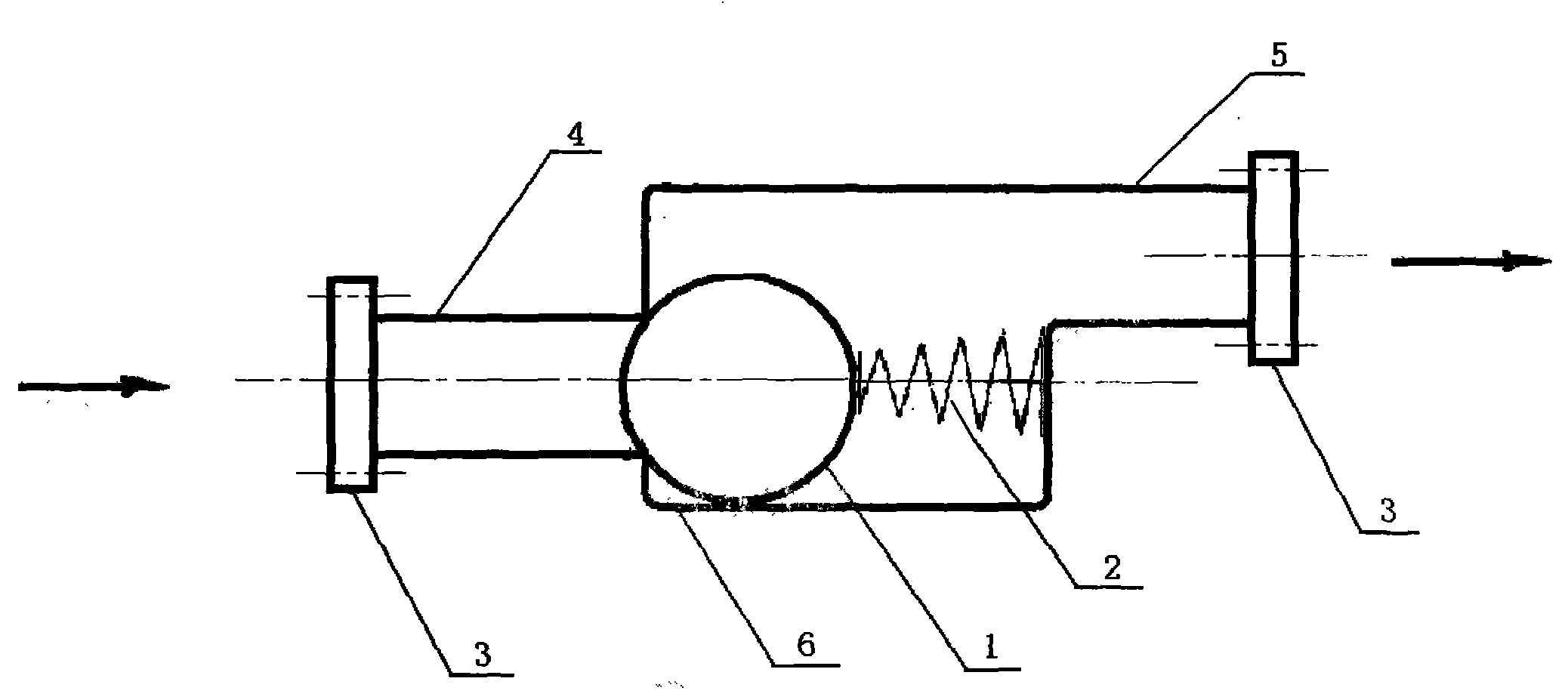

[0022] The hollow ball of the air check valve device of the automobile exhaust pipe should be selected according to the displacement of the automobile. The displacement is large and the mass of the ball is also large. For the environment of super large displacement, high impact force, high temperature and high pressure, the material of the stainless steel hollow ball can also be changed. It is made of ductile iron to increase its strength; in addition, when exhausting, a certain amount of gas will appear behind the hollow ball, which helps to reduce part of the impact force; the diameter of the inlet and outlet pipes should be consistent with the diameter of the original car exhaust pipe.

[0023] The return spring of the air check valve device of the automobile exhaust pipe selects a high temperature resistant conical compression spring. The end face of the big end of the spring is butt-welded with the inner wall, and the end face of the small end of the spring is butt-welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com