Powder coating sprayed through friction gun

A technology of powder coating and friction gun, which is applied in the direction of powder coating, polyester coating, coating, etc., can solve the problem of no friction electrification, achieve high powder coating rate, excellent leveling of coating film, and avoid Faraday effect

Inactive Publication Date: 2015-01-14

ANHUI SHENJIAN NEW MATERIALS

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The material of the friction rod and the pipe wall in the friction gun is a special polymer material PTFE, its dielectric constant is 2.1, and any substance with a higher dielectric constant than its dielectric constant can get a positive charge after friction, but in The dielectric constant of the polyester resin in the powder coating is only about 3.0, and the dielectric constant of other auxiliary materials is even smaller, so the difference between the dielectric constant of the ordinary powder coating and the dielectric constant of the material used in the friction gun is too small, so there is no obvious difference. Triboelectricity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

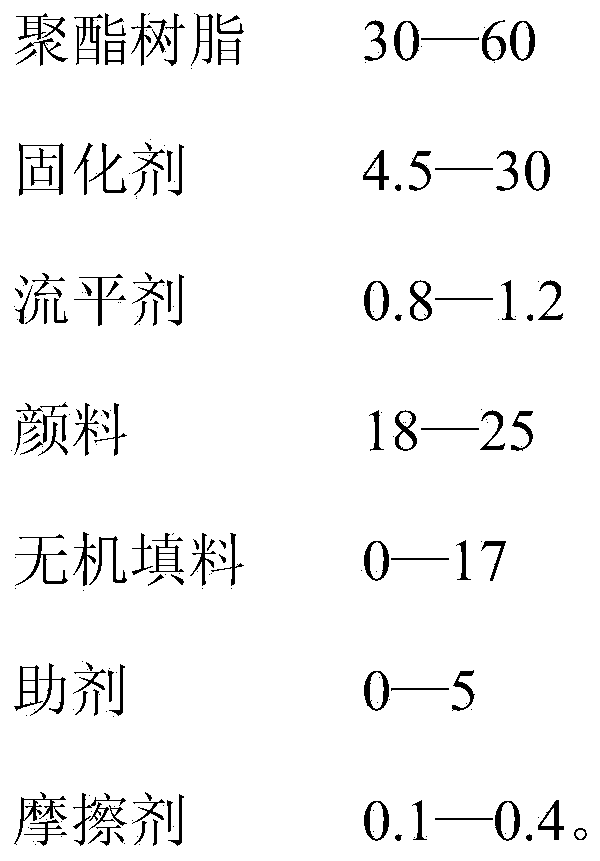

[0025] A kind of powder coating that is used for friction gun spraying, comprises following substance and weight percent:

[0026]

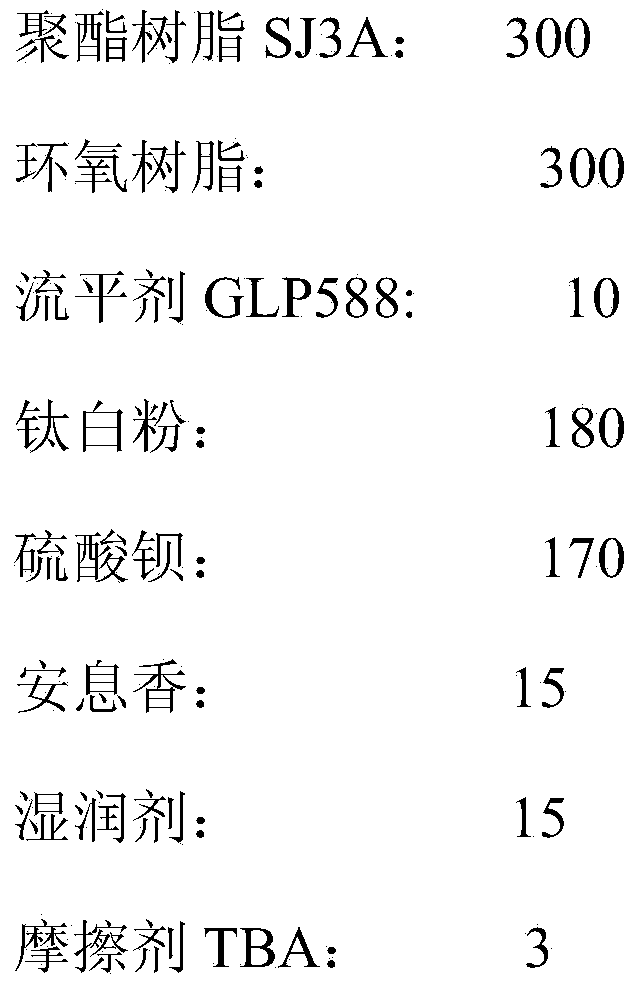

[0027] The polyester resin SJ3A used is produced by Anhui Shenjian New Material Co., Ltd.

example 2

[0029]

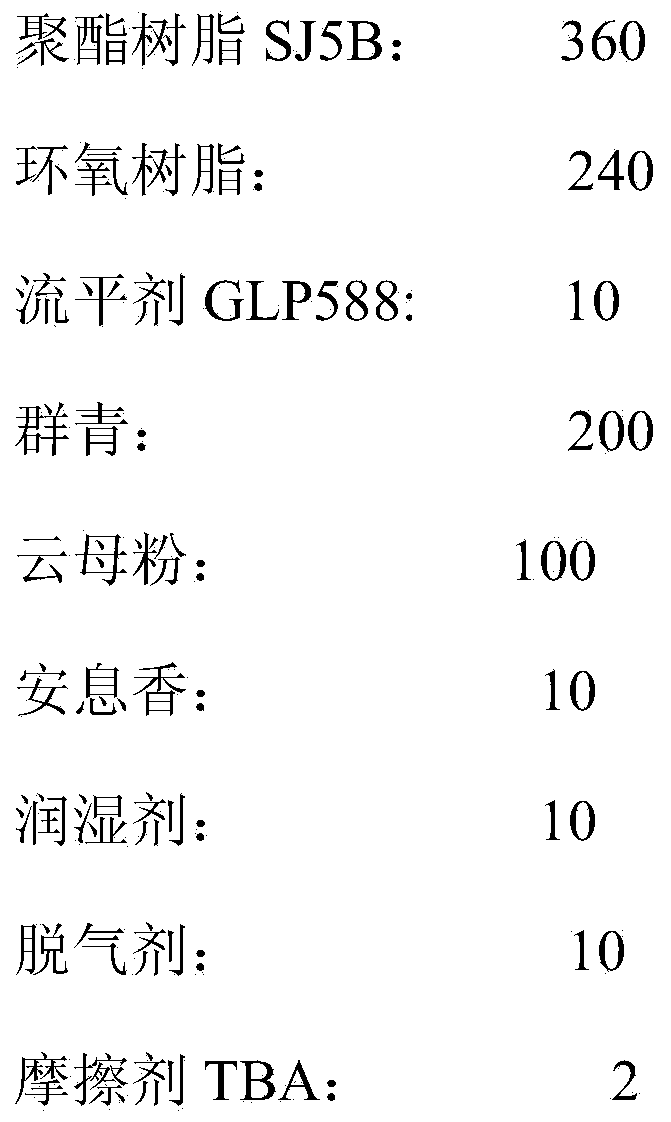

[0030] The polyester resin SJ5B used is produced by Anhui Shenjian New Materials Co., Ltd.

example 3

[0032]

[0033] The polyester resin SJ6B used is produced by Anhui Shenjian New Materials Co., Ltd.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a powder coating sprayed through a friction gun. The powder coating comprises the following substances in parts by weight: 30-60 parts of polyester resin, 4.5-30 parts of curing agent, 0.8-1.2 parts of flatting agent, 18-25 parts of pigment, 0-17 parts of inorganic filler, 0-5 parts of adjuvant and 0.1-0.4 part of friction agent. Due to the introduction of the friction agent, a great difference between dielectric constants of the powder coating and a material (polymer PTFE material) for preparing the pipe wall and a friction rod of the friction gun is generated in the frictional spraying process, so that the powder coating can be perfectly adsorbed on a workpiece after being electrified by virtue of friction with the material in the friction gun under the drive of dry airflow; in addition, the frictional electrification way is adopted, so that the Faraday effect generated by a corona field is avoided, and all corners of the workpiece can be completely coated by the powder coating. Meanwhile, compared with an electrostatic spraying way, the powder coating has the advantages that the powdering rate of the workpiece is higher, and a cured coating film is more excellent in flatting effect.

Description

technical field [0001] The invention belongs to the field of coatings, in particular to a powder coating used for friction gun spraying. Background technique [0002] At present, powder coating spraying processes commonly include electrostatic spraying and friction gun spraying. Electrostatic spraying is widely used in China because of its low requirements for powder coatings. However, due to the generation of corona field and Faraday effect in electrostatic spraying, dead angles will appear in complex workpieces, and some corners are difficult to powder. Although the electrostatic gun has been improved many times, the Faraday effect can only be reduced, but it cannot be avoided. [0003] The friction gun spraying can well solve the problem of powder coating on the dead corners of complex workpieces. The friction gun spraying process has the following advantages: 1. The first powder coating rate is high, which improves efficiency and reduces recycled powder. 2. Overcoming ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D167/00C09D5/03C09D7/12

CPCC09D167/00C08K3/26C08K3/30C08K5/17C08K5/20C08K5/34924C08K2003/265C08K2003/3045C09D5/033C09D7/40

Inventor 刘志坚吴德清汪俊

Owner ANHUI SHENJIAN NEW MATERIALS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com