Test method for evaluating corrosion resistance of coating

A technology of corrosion resistance and test method, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. Layer screening and other issues to achieve the effect of convenient preliminary screening, rapid evaluation, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1. Cut the Q235 steel into a test piece with a size of 25mm×60mm×2mm, and perform sandblasting on the surface, and clean it for later use;

[0039] Step 2. Use electrostatic spraying technology to evenly spray a Teflon coating on the surface of the test piece to obtain a test piece 1. The Teflon coating should completely cover the test piece 1. Take pictures to record the coating morphology. Measure 1 three times, take the average value, and obtain the size of test piece 1: 27.20mm×62.12mm×5.26mm, and the mass is 15.8978g;

[0040] Step 3, configure the corrosion solution in the reactor, wherein the mass ratio of each component is liquid bromine: water: n-hexane = 0.5: 1.5: 98, and install the test piece 1 in the reactor lined with polytetrafluoroethylene ;

[0041] Step 4. Place test piece 1 in the reaction kettle for hanging test, take the piece after 24 hours, clean the surface and dry to get test piece 2;

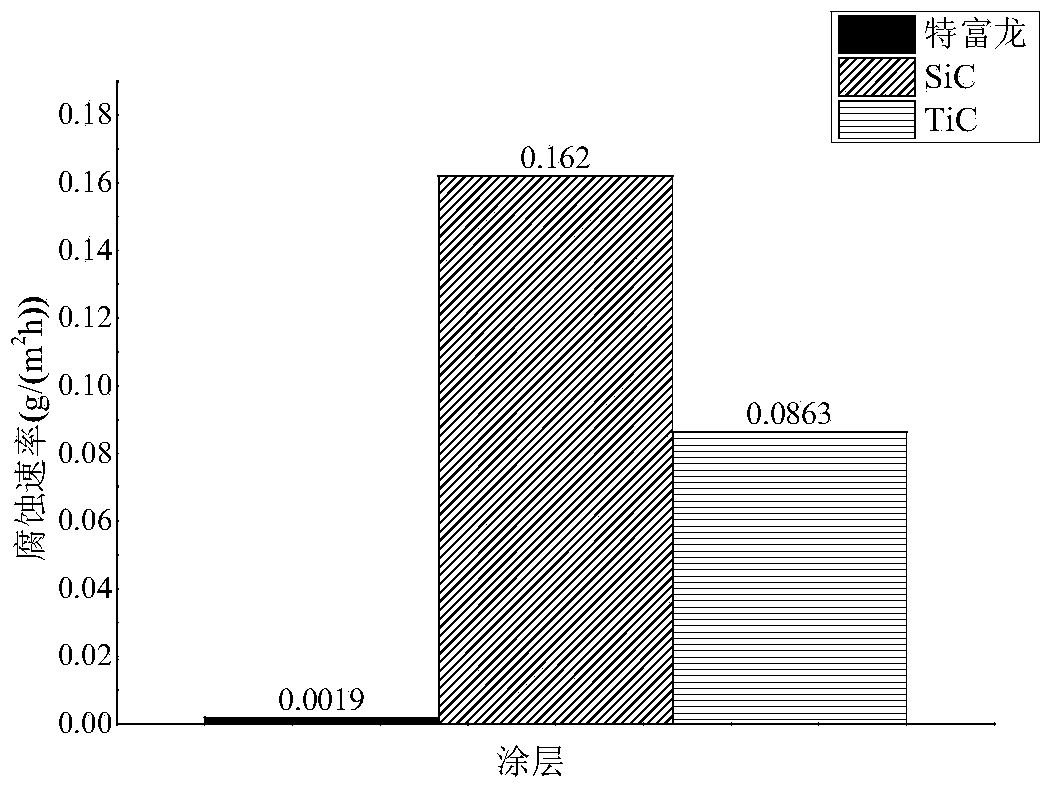

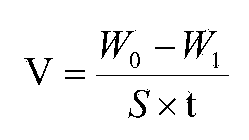

[0042] Step 5. After the test, the test piece 2 was ...

Embodiment 2

[0045] The difference from Example 1 is that in step 2, a ceramic coating containing SiC is uniformly sprayed on the surface of the test piece by plasma spraying technology to obtain a test piece 1, the size of which is 27.14mm×62.08mm×5.18 mm, the mass is 18.2465g.

[0046]In step 5, the mass of the test piece 2 after the experiment is 18.2298g, and the weight loss of the test piece before and after the test is calculated by the formula (1) by the weight loss method to be 0.0167g, and the corrosion rate is 0.1620g / (m 2 h).

Embodiment 3

[0048] The difference from Example 1 is that in step 2, a ceramic coating containing TiC is evenly sprayed on the surface of the test piece by using plasma spraying technology to obtain a test piece 1, and the size of the test piece 1 is 27.12mm×62.10mm×5.20 mm, the mass is 18.8531g.

[0049] In step 5, the mass of the test piece 2 after the experiment is 18.8442g, and the weight loss of the test piece before and after the test is calculated by the formula (1) by the weight loss method to be 0.0089g, and the corrosion rate is 0.0863g / (m 2 h)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com