Direct measuring method for single-well crude oil gas yield

A measurement method and technology of crude oil, which is applied in measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of difficult measurement, complex crude oil environment, and technical difficulty of accurate crude oil measurement equipment, and achieve the effect of simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

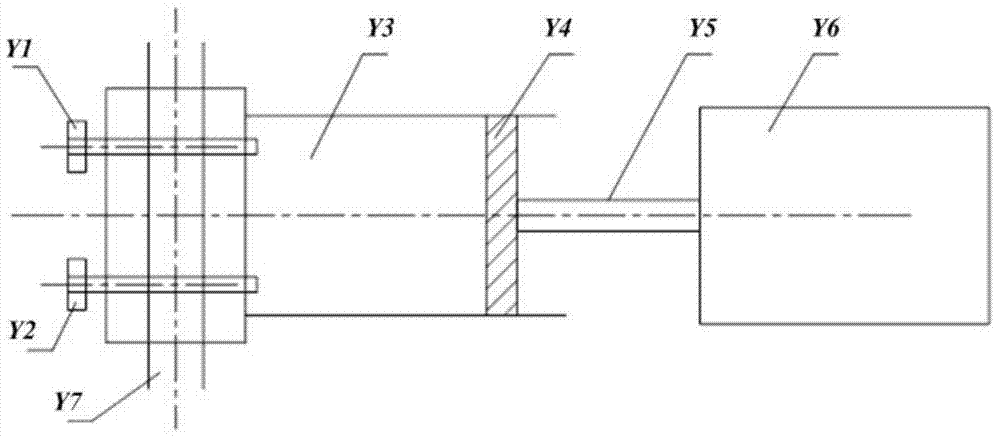

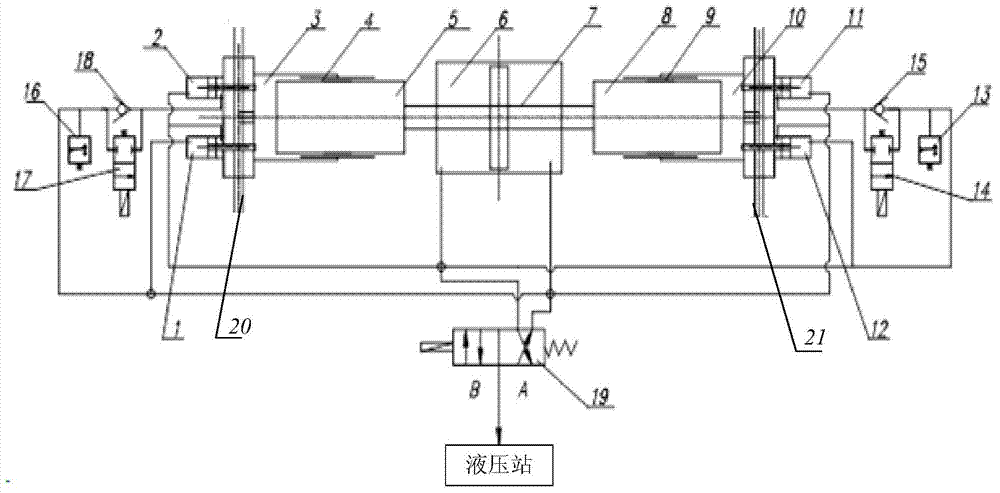

Method used

Image

Examples

Embodiment 1

[0093] The compressible airtight container collects the sand-removed oil-water mixture produced by a single well within 1 second through the inlet port connected to the oil pipeline. After the collection is completed, the pressure sensor, temperature sensor, density meter and volume measuring meter connected to the airtight container The pressure of the gas in the airtight container was measured to be 0.3MPa, the temperature was 30°C, and the density of the oil-water mixture was 900kg / m 3 And the volume of the airtight container is 0.001m 3 , record the data or transmit the data to the computer; after the measurement is completed, compress the airtight container to a certain degree, and then measure the pressure of the gas in the airtight container to be 0.9MPa, the temperature to be 35°C and the volume of the airtight container to be 0.0005 m 3 , also record or transfer data to a computer. Take the density of water in crude oil as 1000kg / m 3 , the density of oil in crude o...

Embodiment 2

[0095] The compressible airtight container collects the sand-removed oil-water mixture produced by a single well within 0.5s through the inlet port connected to the oil pipeline. After the collection is completed, the pressure sensor, temperature sensor, density meter and volume measurement connected to the airtight container The pressure of the gas in the airtight container is 0.1MPa, the temperature is 20°C, and the density of the oil-water mixture is 960kg / m3 respectively. 3 And the volume of the airtight container is 0.01m 3 , record the data or transmit the data to the computer; after the measurement is completed, compress the airtight container to a certain extent, and after it is stabilized, measure the pressure of the gas in the airtight container to be 0.25MPa, the temperature to be 25°C and the volume of the airtight container to be 0.005 m 3 , also record or transfer data to a computer. Take the density of water in crude oil as 1000kg / m 3 , the density of oil in ...

Embodiment 3

[0097] The compressible airtight container collects the sand-removed oil-water mixture produced by a single well within 2 seconds through the inlet port connected to the oil pipeline. After the collection is completed, the pressure sensor, temperature sensor, density meter and volume measuring meter connected to the airtight container The pressure of the gas in the airtight container was measured to be 0.5MPa, the temperature was 40°C, and the density of the oil-water mixture was 880kg / m 3 And the volume of the closed container is 0.5m 3 , record the data or transmit the data to the computer; after the measurement, compress the airtight container to a certain degree, and after it stabilizes, measure the pressure of the gas in the airtight container to be 1MPa, the temperature to be 43°C and the volume of the airtight container to be 0.3m 3 , also record or transfer data to a computer. Take the density of water in crude oil as 1000kg / m 3 , the density of oil in crude oil is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com