A kind of weaving method of body temperature sensor fabric

A body temperature sensor and fabric technology, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of easy slipping in fabrics, poor coating effect, and the influence of accurate body temperature measurement, etc., to achieve small size and improve comfort , little effect on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

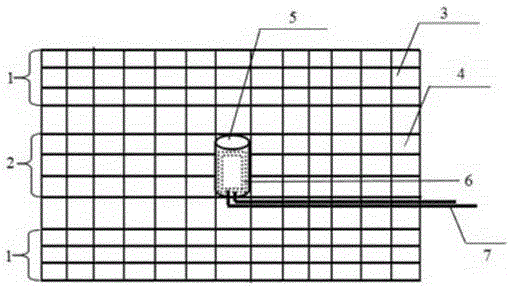

Image

Examples

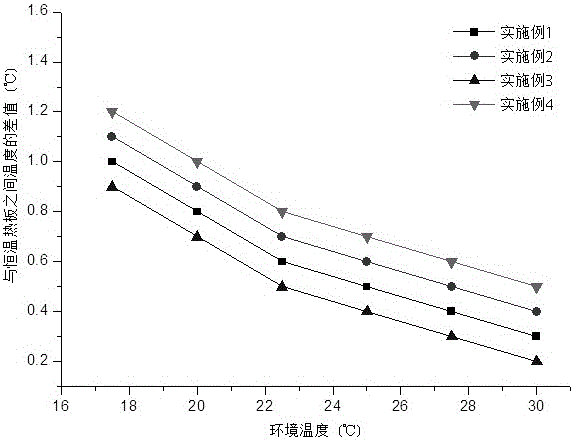

Embodiment 1

[0032] The warp yarn of the fabric is 30tex cotton yarn, the weft yarn of the first basic unit block is 20tex cotton yarn, the weft yarn of the second basic unit block is 300D / 96F high-shrinkage polyester filament, and the above-mentioned yarn is used as the yarn for fabric weaving to carry out the body temperature sensor fabric Weaving, through the following steps:

[0033] (1) Winding

[0034] 30tex cotton yarn, 20tex cotton yarn and 300D / 96F high-shrinkage polyester filament are wound by XFJ118M high-speed electronic winder. The processing speed of 30tex cotton yarn is 950m / min, and the processing speed of 20tex cotton yarn is 900m / min , The processing speed of 300D / 96F high-shrinkage polyester filament is 1000m / min, which can be processed into a package yarn that meets certain requirements and has a large yarn capacity. This can significantly improve the quality of cotton yarn and high-shrinkage polyester filament, which is beneficial to Improve the production efficiency ...

Embodiment 2

[0049] The warp yarn of the fabric is 30tex polyester yarn, the weft yarn of the first basic unit block is 20tex cotton yarn, the weft yarn of the second basic unit block is 300D / 96F high-shrinkage polyester filament, and the above yarn is used as the yarn for fabric weaving, and the body temperature sensor Fabric weaving, through the following steps:

[0050] (1) Winding

[0051] 30tex polyester yarn, 20tex cotton yarn and 300D / 96F high-shrinkage polyester filament are wound by XFJ118M high-speed electronic winder. The processing speed of 30tex polyester yarn is 980m / min, 20

[0052] The processing speed of tex cotton yarn is 900m / min, and the processing speed of 300D / 96F high-shrinkage polyester filament is 1000m / min.

[0053] m / min, it can be processed into package yarns that meet certain requirements and have a large yarn capacity, which can significantly improve the quality of polyester yarns, cotton yarns, and high-shrinkage polyester filaments, and is conducive to impr...

Embodiment 3

[0066] The warp yarn of the fabric is 30tex ramie yarn, the weft yarn of the first basic unit block is 20tex cotton yarn, the weft yarn of the second basic unit block is 300D / 96F high-shrinkage polyester filament, and the above-mentioned yarn is used as the yarn for fabric weaving to perform body temperature sensor Fabric weaving, through the following steps:

[0067] (1) Winding

[0068] 30tex ramie yarn, 20tex cotton yarn and 300D / 96F high-shrinkage polyester filament are wound by XFJ118M high-speed electronic winder. The processing speed of 30tex ramie yarn is 950m / min, 20

[0069] The processing speed of tex cotton yarn is 900m / min, and the processing speed of 300D / 96F high-shrinkage polyester filament is 1000m / min.

[0070] m / min, it can be processed into package yarns that meet certain requirements and have a larger yarn capacity, which can significantly improve the quality of ramie yarns, cotton yarns, and high-shrinkage polyester filaments, and is conducive to improvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com