Biphasic stainless steel line pipe with yield strength of 555 MPa or above and manufacturing method thereof

A duplex stainless steel, yield strength technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A17 and comparative example B1-B5

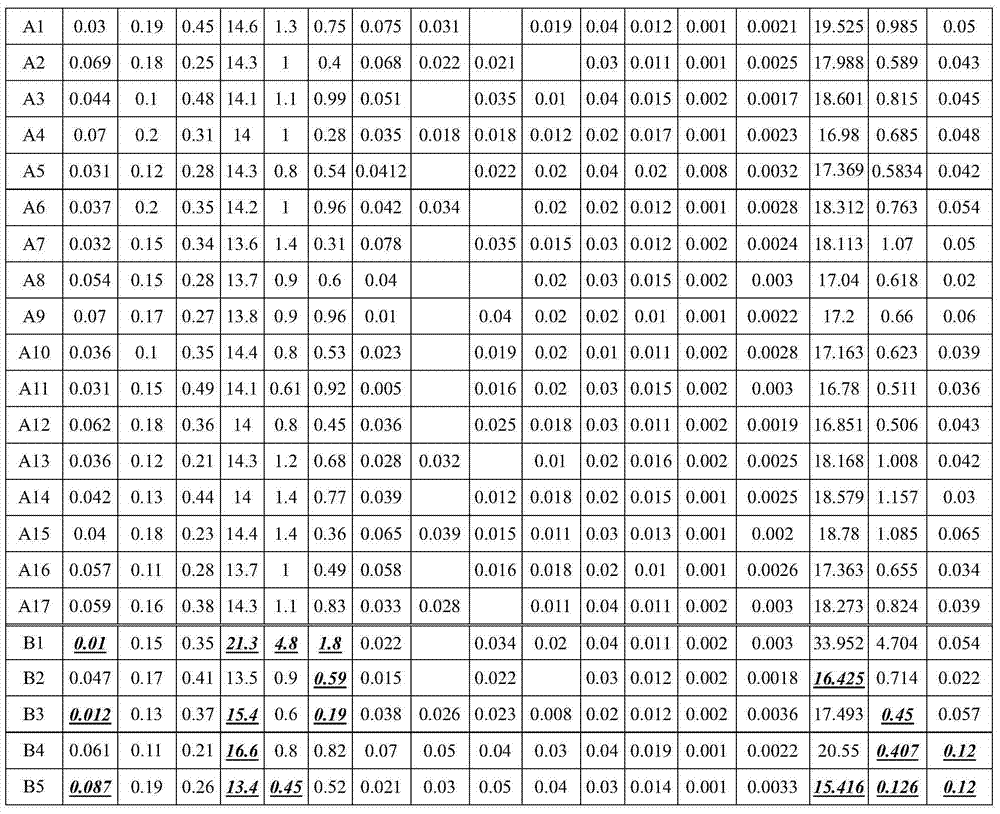

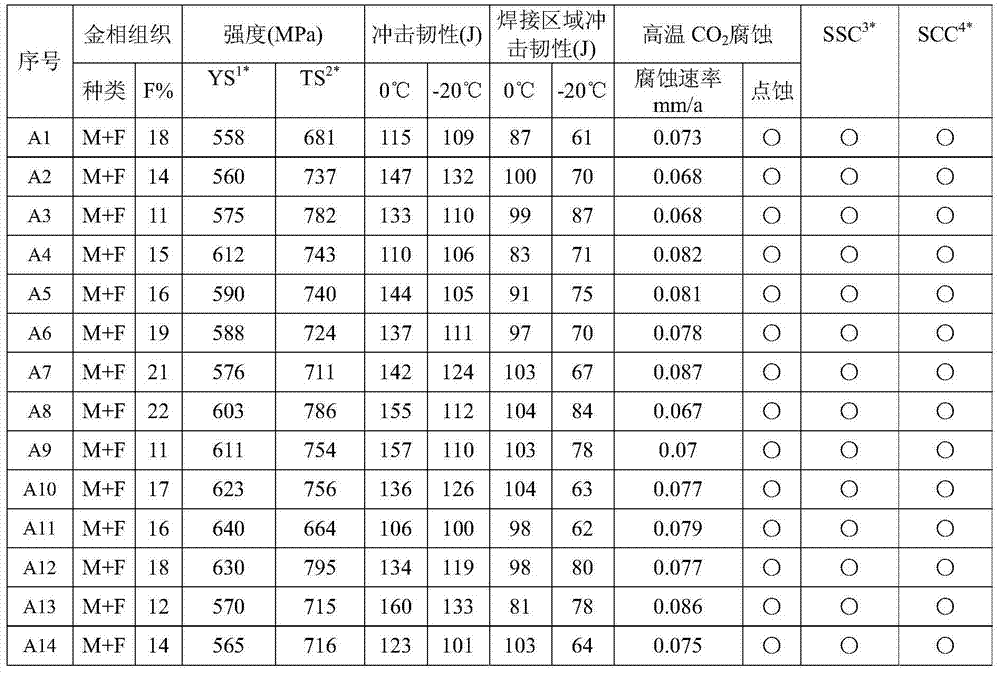

[0042] The duplex stainless steel linepipes in Examples A1-A17 and Comparative Examples B2-B5 were fabricated as follows:

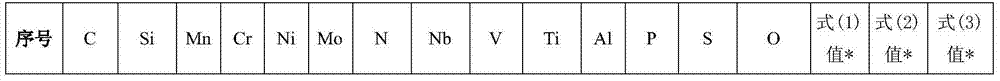

[0043] 1) smelting: control the mass percentage distribution of each chemical element in Examples A1-A17 and Comparative Examples B1-B5 as shown in Table 1;

[0044] 2) Pipe making: making raw materials into seamless steel pipes;

[0045] 3) Quenching: heat the steel pipe to a temperature above 900°C for 30 minutes, and cool it to below 150°C with a cooling rate above air cooling;

[0046] 4) Tempering: Temper the steel pipe at 610-670°C for a holding time of 60 minutes;

[0047] 5) The volume percentage content of ferrite in each steel pipe obtained after air cooling is shown in Table 3.

[0048] The specific process parameters involved in the above steps are shown in Table 2.

[0049] The duplex stainless steel (ferrite + austenite) linepipe of Comparative Example B1 was manufactured and implemented according to the following steps:

[0050] 1) Smel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com